Working with your lab: How can you streamline the process?

Dental labs accomplish amazing things.

When you think about it, the process of creating a restoration is sort of a miracle. The fact that a piece of human anatomy can be replicated quickly and at reasonable expense is nothing short of astounding.

But when you add new technology and materials-like CAD/CAM and monolithics-producing better, faster, cheaper restorations becomes even more impressive.

It’s not really a miracle, though. It’s hard work between the clinician and the laboratory. To optimize the endeavors of both parties, they must be able to work together smoothly.

What your labs want you to know

Lab owners say the same thing as doctors when it comes to having a fruitful relationship-they want good communication.

“Communication is killer,” said Shaun Keating, owner of Keating Dental Arts in Irvine, Calif. “It’s king when it comes to working with a dental office. That’s everything from the front desk staff to the assistants to who’s packing the cases. It’s important that we all work together as a team.”

The more information the doctor shares with the lab, the better the results.

“Have them draw a little picture on the lab script, too,” Keating added. “If they’re breaking down from the incisal third to the middle third to the gingival third, it’s kind of nice to break it down a little bit if we don’t have a picture, so the ceramist can try to layer that in, or to surface stain it if it’s something like a monolithic or a pressed type (IPS) e.max. As much information as we can get is always nice. A picture’s worth a thousand words when it comes to ceramics or designing.”

In many cases, if your lab knows you, how you work and what you typically want, its can help catch problems.

“It’s about the open communication,” said Bob Savage, CFO at Drake Precision Dental Lab in Charlotte, N.C. “I think Drake always tries to take a proactive approach with its clients, whether we notice that the prescription is maybe different from what the doctor normally prescribes, if it’s a long-standing customer or if material selection seems maybe not appropriate for the particular case, we always try to contact our doctors and talk about it. We really do feel that the input we bring and what the clinician brings to the table, if we can meld those together, is the success of the case for the patient.”

Best practices

Successful doctors offer advice for working with their own labs.

“Provide the necessary information,” said Dr. Bob Mongrain, DMD, at Berkshire Dental Group in Broken Arrow, Okla. “Provide a good impression, adequate lab slips that give the necessary detail and good photos as appropriate. Today, with digital photography, it’s so easy to send really high-quality photos by email. Some labs are very digitally oriented and others are not, but make sure your lab is digitally oriented and provide them that information.”

Finding time to strategize with your lab on cases will result in better end results.

“Ask to have a conversation,” Dr. Mongrain said. “Lab techs can give you advice on things that’ll keep you out of trouble. It’s a really good idea to take several minutes. You’re looking at the photos, and the lab tech is looking at the photos; just walk through it. That can make a huge difference. The lab doesn’t always know when it should be reaching out because it doesn’t know what’s coming from the doctor.”

While techs can do some impressive things in the lab, they aren’t mind readers.

“Don’t expect them to be magicians,” said Dr. John Comisi, DDS, president and CEO of Dental Care With a Difference in Ithaca, N.Y. “If you don’t give them the heads up on what you’re doing ahead of time, they’re not going to be able to guess what you need, especially if you’re not sending them the appropriate scans, impressions, wax-ups or models you need to get before you do the case.”

There are intangibles involved with a successful doctor/lab relationship.

“What you need to do is find a lab that you can work with, and it’s interesting because in a way I feel it’s kind of like a marriage,” said Dr. John Flucke, DDS, chief dental editor and technology editor for Dental Products Report. “You need to find somebody you can get along with. You need to find somebody that does have your best interests at heart or the patient’s best interests at heart, and you’re not always going to have the same personality, but I do think it’s important to work on finding people whose personalities mesh. That’s not always just a matter of finding somebody that has the lowest prices or can offer the shortest turnaround or whatever it is. Some of it is finding somebody who just thinks like you and has the same goals as you do.”

Use your resources

Doctors are wise to look to their labs as useful resources-resources that can be tapped when unusual cases arise.

“As a doctor, I do routine dentistry,” Dr. Flucke said. “Let’s say that I come up with some kind of oddball situation, and, from a lab standpoint, I’m going to be pushing the envelope on a case. As a doctor, I may bump into one of those envelope-pushing cases maybe once or twice a year, but, my laboratory may bump into those cases once a week, once a month or whatever. I count on the lab to be just like an adjunct team member in the office so that I’m going to do something, and I’m going to push the envelope, and I contact the lab, and I ask them their advice.”

“They’re there as a resource to help guide you through procedural challenges that you may have above and beyond the usual techniques that you know,” Dr. Comisi added. “Sometimes a lab tech can give you insights as to appropriate preparation for a particular type of material or a crown, how to look at how to plan for your implant cases or your full reconstructions. Communication with a lab, in that respect, is going to be really, really important-both from what you give the lab to work with and from what they give you back as far as feedback.”

Be sure to take advantage of all the resources your lab offers.

“For me, it’s leveraging the digital capabilities,” Dr. Mongrain said. “My lab has a portal, and many of the larger labs have portals now, but I haven’t taken the time to educate myself about that and the ways the labs can streamline communication for me. Labs are working hard to utilize the digital capabilities that we have, and dentists need to take the time to educate themselves about what their lab provides and how they can streamline that process.”

Labs offer prospects for assistance; doctors just need to take advantage of those opportunities.

“Usually, when you start working with a new lab, they always send you an information package that contains lab slips, costs for particular cases or people to contact. Some of them are even nice enough to provide technique design recommendations and other things to work with certain materials in ceramics, etc.,” Dr. Comisi said. “That’s great because that gives us an opportunity, if we read what they send us. Unfortunately, many doctors are of the mindset that they know everything and they don’t need the lab to tell them what to do. Even after 30 years, I’m still learning from the people at the labs I work with. They continue to give me insights as to how to make what I am doing better. The lab technicians know about most of these things well before the majority of the doctors out there do. Who better to get some real good insight as to the pros and cons of a particular material than your technician? They’re an important part of the dental team. They’re as important as my assistants, my hygienist and my front office people. They’re part of what makes me better.”

Strengthen communication

To get the best work from your lab, you must provide it the best information. Without enough detail, the lab can’t know enough to give you back what you want.

“The more information you give to the lab, the better the final outcome,” said Dr. Sheri Doniger, DDS, president, American Association of Women Dentists. “The impression must be perfect or the final restoration won’t be perfect. If you send something ‘iffy’, don’t expect miracles. I know labs will not critique doctors, but it is important that doctors are open to suggestions.”

The size of the lab can affect your results, and routinely working with the same techs helps.

“Let’s say I’ve decided to change to a large lab, and the first case I send to them, they give to a lab tech with 30 years of experience, and I get the case back, and I think, ‘Oh my gosh, this is amazing! Where have you been my whole career? I love it,’” Dr. Flucke illustrates. “So I send them another case, and because it’s a large lab with a large number of employees, then I get the guy with one year of experience. So now I get the case back and I think, ‘Holy cow! Where’s the quality control? This isn’t anything like I got the first time.’ I think that’s one of those things where a lab needs to do the best that it can to get the cases in the hands of lab techs so the doctor gets to know the same lab tech over and over and over. So you get a working relationship with them and they know what you want, and that does not happen.”

Taking the lead with new products

Introducing a new product or material into the doctor/laboratory relationship can occur in several different ways. In some cases, the lab takes the lead.

“Generally, it’s the laboratory because it’s in its best interest to be able to continue to receive work from a doctor that’s made the switch to technology,” said Ryan Faufau, director of CAD/CAM resources at Custom Milling Center in Arvada, Colo. “One of the fears I see with most labs is that everything’s going digital and doctors aren’t taking impressions today. How do I maintain this working relationship with the clinician to continue to receive work and keep control of the account?”

Oftentimes, doctors are too busy to keep up with what’s new so the lab brings it up.

“If the doctor is reading journals and the literature, they’re going to be finding out about the new materials, but sometimes the day is too packed and crammed to know about all the different things that are out there,” Dr. Comisi said. “Many labs will send out brochures and leaflets regarding new techniques and materials that are available, and most of them say, ‘Call us to learn more about this material, how to work with it and what you can do.’ Technicians can give some great information. If the technicians are staying up and they are trained on these things, oh my gosh, you can’t get a better insight and a better team member.”

Sometimes the new product or material is introduced into the relationship organically when discussing a case’s improvement.

“Our client services people may bring it up to an account,” Savage said. “Our technical people, as they’re talking about a case, maybe they’re having a problem on this case with a material and maybe this new material is a good option or, ‘Hey, maybe on your next case similar to this, we have this XYZ product that may really fit into that particular modality of the case.”

“What I see is primarily manufacturers and key opinion leader speakers that start talking about a new material and then the labs follow behind them to introduce them to use their clients,” Dr. Mongrain added. “They’re usually talking to me before I’m talking to them.”

The type of product also is a factor in who introduces it into the relationship.

“In my case, when it’s a device, like a scanner, I’ll often bring that to the attention of my lab,” Dr. Flucke said. “As far as materials, they will bring that to my attention because they’re more versed in the materials than I am, but I’m a bit of an outlier from the device standpoint because I’m a gearhead and I’m always looking for gadgets and stuff to try.”

New equipment, new work methods

With new products and techniques, there are new ways to handle the workflow between doctor and laboratory.

“The expectation level changes a bit,” Savage said. “You used to box an impression up and you get it the next day. With digital, I think there’s a growing expectation of immediate access. That impression is now in our hands. Is it good while the patient’s still in the chair? It sets a different expectation level for us. I don’t think the communication really changes, but I think it speeds it up, and I think it’s up to the lab to be responsive to that in understanding that, going forward, as more digital impressions and CAD/CAM-type restorations enter into a lab, you have to be cognizant of that expectation change.”

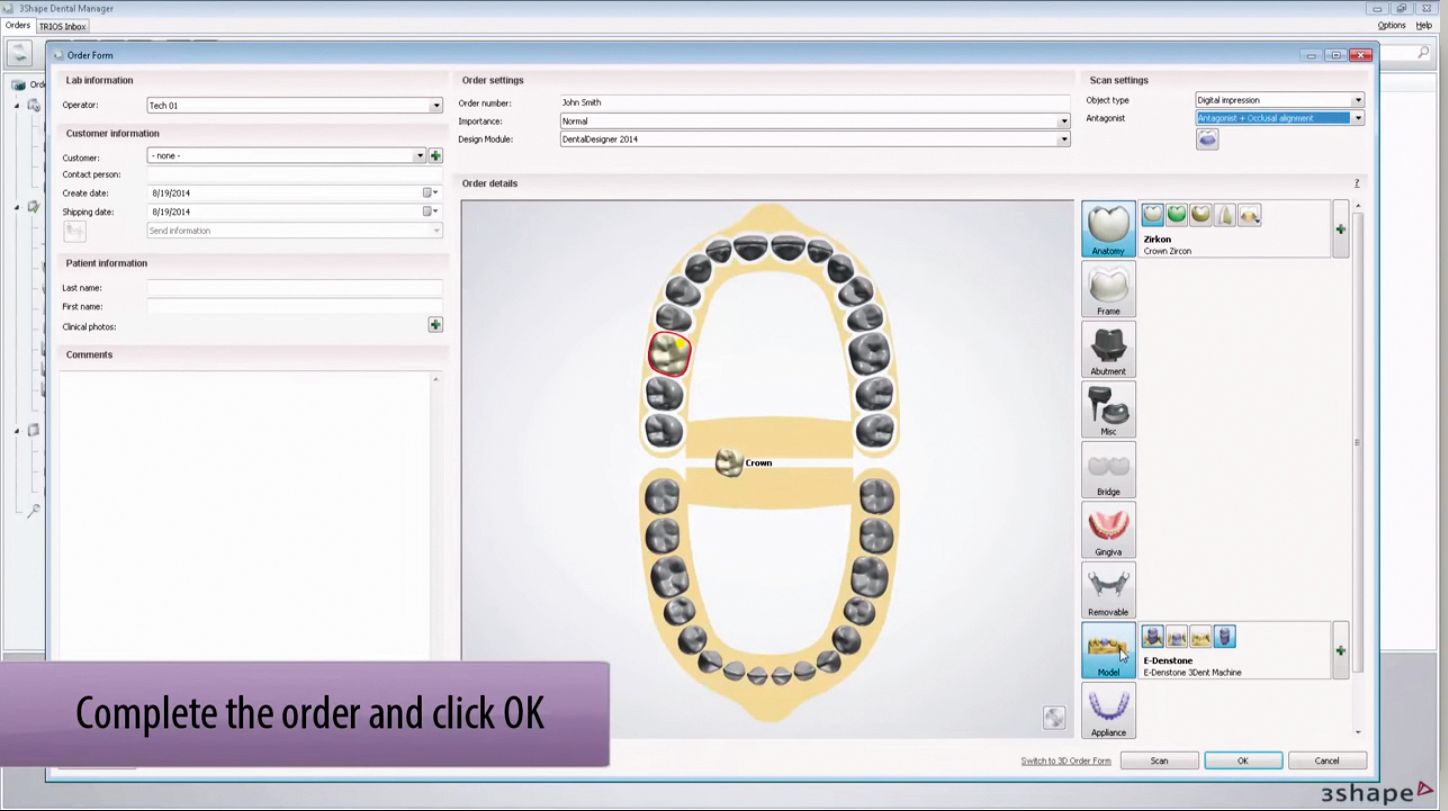

Dr. Comisi has gone from traditional impression techniques to using a 3Shape scanner for an all-digital workflow.

“It’s made me, in my opinion, a better doctor overall simply because as I’m preparing, after I’ve scanned, I can really scrutinize,” Dr. Comisi said. “I can blow that picture up and see were my margin is or, even worse, not see where my margin is. And I can correct it before I send that off to the lab. Since I’ve gone digital, I’m just looking at this and I say, ‘Oh my gosh, I see things that I wouldn’t have seen otherwise,’ and it’s really remarkable.”

The ability to send the case electronically helps not only in terms of speed and efficiency, but it also gives the lab a chance to look at it while the patient is still in the chair.

“The communication there is instantaneous,” Dr. Comisi said. “Once I send an STL file to the laboratory, they’ve got it within minutes. The technicians who open up the file look at the case, and, shortly thereafter, I get a notification whether the case has been accepted or not, so I know right away if there’s a problem with my case. That’s great because I may have that notice before I dismiss the patient, and I can correct the problem. That’s really the great thing that goes on for most of these but especially with the mobile apps that are available with many of the systems. You get a notice on your telephone that something’s going on on the TRIOS app, and they look at it and say, ‘OK,’ and the lab has communicated with you. Then you type back and you tell them what you want, ask them to clarify it more or just get on the horn and talk to them.”

To facilitate that exchange of data, labs and doctors use online portals.

“If the doctor has a chairside scanner, how do they get that data submitted over to the laboratory and how do we make this as easy as possible,” Faufau observed. “One of the things we do at Custom Milling Center is we help laboratories set this workflow between the laboratory and the doctor. We use a program called DDX, which is Dentrix. It’s actually an online web-based program that enables the clinician to create an account through their website. The laboratory would create an account, and this is how they both would connect. The clinician would be able to simply pull up the web browser, attach the file and submit the case to the laboratory without purchasing additional software.”

Tools like DDX not only facilitate the exchange of information, they also ensure regulatory compliance.

“I think it’s becoming more common because one of the things that we also have to look at when we’re sending RXes and patient information over the web is, ‘Is this HIPAA-compliant?’ ” Faufau says. “Is it following patient privacy? And DDX follows all those guidelines, which I think is something that might be overseen in the industry today, especially when it comes to electronic submission.”

New materials

A major shift in dental work has come with CAD/CAM, both through the involvement of digital dentistry and also the materials used to produce those restorations.

“The dentists are transitioning,” said Jason Obrokta, director of technical marketing, Fixed Prosthetics at Ivoclar Vivadent. “We are in this transitional phase. The normal thing was for a doctor to prescribe a metal-based restoration, and they’re starting to transition away from that and into these all-ceramic restorations where there’s no metal involved at all in it.”

As the technology has evolved, the materials have grown easier to work with.

“In the past, you had to do very specific things to be able to utilize an all-ceramic crown or an all-ceramic restoration,” Obrokta said. “Now, because we’ve got stronger materials, it gives a little bit more forgiveness in the applications they can be used in and the number of ways a doctor can do things incorrectly and still have a successful result.”

Given the material evolution from traditional restorations, some doctors might be resistant to the change. It usually takes a nudge from an associate to get a dentist to try new materials.

“Colleague referrals are where we start to see a lot of people take notice-they’re hanging out together and somebody says, ‘Have you ever tried an e.max crown?’ ‘ No I haven’t, why? What’s the big deal?’ ‘It looks better. It doesn’t have metal. My patients have been asking for it. My laboratory is promoting it because it’s a better restoration. It doesn’t break; it doesn’t crack.’ ”

“I feel like that cohort recommendation is really kind of what will prompt some of those laggards to take a look at it and go, ‘Oh, yeah, maybe I should be using this,’ ” he said.

Scott Clark, president of Dental Arts Laboratories (DAL) in Peoria, Ill., stresses the need for educating customers, as this area of the industry is always evolving.

“With clinical procedures, digital materials and manufacturing changing so rapidly, DAL makes a concentrated effort to educate our dentist customers through forums such as The Dawson Academy. Additionally, we lecture extensively on material selection guidelines, cementation recommendations and adjust/polishing procedures,” Clark said. “With new high strength, translucent ceramics coming to market such as our cubeX2 cubic zirconia, it is extremely important that we effectively educate our customers as to the indications of these new products and the proper clinical steps with each material.”

Teamwork

For the best working relationship-and for the best results-clinicians and their labs must work as a team. To smooth out complex cases, Dr. Flucke brings each member of the team together.

“What I’ve seen is the lab will call me and say, ‘You know, John, we’re going to have a hard time getting this the way you want it because the surgeon or the periodontist didn’t put these where they need to be for easy restorability or for angulation or whatever,” Dr. Flucke said. “Unfortunately, in those situations, the general dentist becomes caught in the middle. So what I’ve started doing when we get complicated things-and this is something I would really advise with cases like this-if there is a chance that it could go haywire, have a meeting.”

That meeting can be done in person or even through conference calls or virtually. In Dr. Flucke’s case, he built a conference room in his building with a screen so he can host meetings. He brings in the lab tech and any specialists and puts the case on the wall so they can all go over the details together.

“We can review the X-rays, photos, everything,” Dr. Flucke said. “We can all treatment plan the case together so that we all know the nuances of it. It’s nice to do that because you end up with a case that everybody is involved with from the ground floor. I have no problem with having a big meeting and getting everybody together and making the decisions together as a group so that we all know where the limitations are with different potential stopping points.”

Realizing the skills and talents of the other members of your team will help you deliver the best for the patient.

“It’s definitely an interesting time, but regardless of whether it’s CAD/CAM or whether it’s traditional impressions, communication is a very big piece to our business,” Savage said. “We have to communicate because I think both parties bring different talents and different experiences to the table. We learn from our clients, and I hope that our clients learn from us because that’s the way it should be and can really build a synergistic relationship and not be just one-way communication.”

Ultimately, a successful relationship depends on solid communication.

“The most important thing they can do is communicate,” Dr. Comisi said. “Talk. Ask questions. Share the knowledge base together with your teammates. Make sure that everybody is aware of what’s going on so that this way disagreements and challenges can be reduced. That’s where you’re going to can find it. If we talk, we’ll find solutions.”