How to choose material that provides optimal end results, with efficiency and predictability

One of the greatest challenges in dentistry is the placement of metal-ceramic restorations which achieve a harmonious and esthetic appearance with adjacent natural dentition. Therefore, laboratory technicians require materials that offer outstanding esthetics, high strength and efficient productivity.

One of the greatest challenges in dentistry is the placement of metal-ceramic restorations which achieve a harmonious and esthetic appearance with adjacent natural dentition. Therefore, laboratory technicians require materials that offer outstanding esthetics, high strength and efficient productivity.

Fortunately, Ivoclar Vivadent’s IPS InLine metal-ceramic and Protocol Alloy enable ceramists to achieve highly predictable and esthetic results when porcelain-fused-to-metal (PFM) restorations are needed.

To enhance productivity and efficiency, IPS InLine only requires one application of a combined dentin/incisal material with the desired chroma and translucency. Balanced coordination of translucency and shade saturation produces restorations with optimal optical properties and a consistent, true-to-nature shade. The IPS InLine leucite-containing veneering ceramic materials are easy to apply and do not require any special knowledge of layering techniques. Therefore, they are ideal for conventionally layering PFM restorations.

This article demonstrates the natural esthetics that can be achieved using IPS InLine PFM crowns. In this case, a 19-year-old female presented with a congenitally missing lateral incisor, for which she wore a flipper (Fig. 1).

A diagnostic wax-up was made, and implant surgery to replace the missing tooth was recommended, accepted, and later undertaken. The surgeon placed a Nobel Active Narrow Platform (NP) (Nobel Biocare) implant.

Following surgery, a provisional restoration created from the wax-up was bonded into place (Fig. 2). Months later, the patient returned for opening of the soft tissue and exposure of the implant head. At this time, a screw-retained provisional crown restoration was developed to the final shape of the soft tissue for the definitive restoration. After the provisional restoration was screwed into place, the patient was checked every two weeks until the tissue contouring was satisfactory (Fig. 3).

To fabricate the definitive restoration, impressions were made using a flowable composite around the area and between the impression coping and soft tissue, which copied the shape of the soft tissue that had been developed with the provisional restorations (Fig. 4). Next, the impression was poured using Fuji Rock (GC America) and Gingitech Gingival mask material (Figs. 5a and 5b).

In this specific case, a UCLA-type porcelain-fused-to-metal (PFM) restoration that was cast with Protocol Alloy and veneered with esthetic porcelain IPS InLine was selected. This alloy selection was compatible with the coefficient of thermal expansion of the chosen ceramic (i.e., 13.8-14.5).

Laboratory technique/Fig. 6

01 The color for the definitive restoration-2M2- was selected and converted to A2.

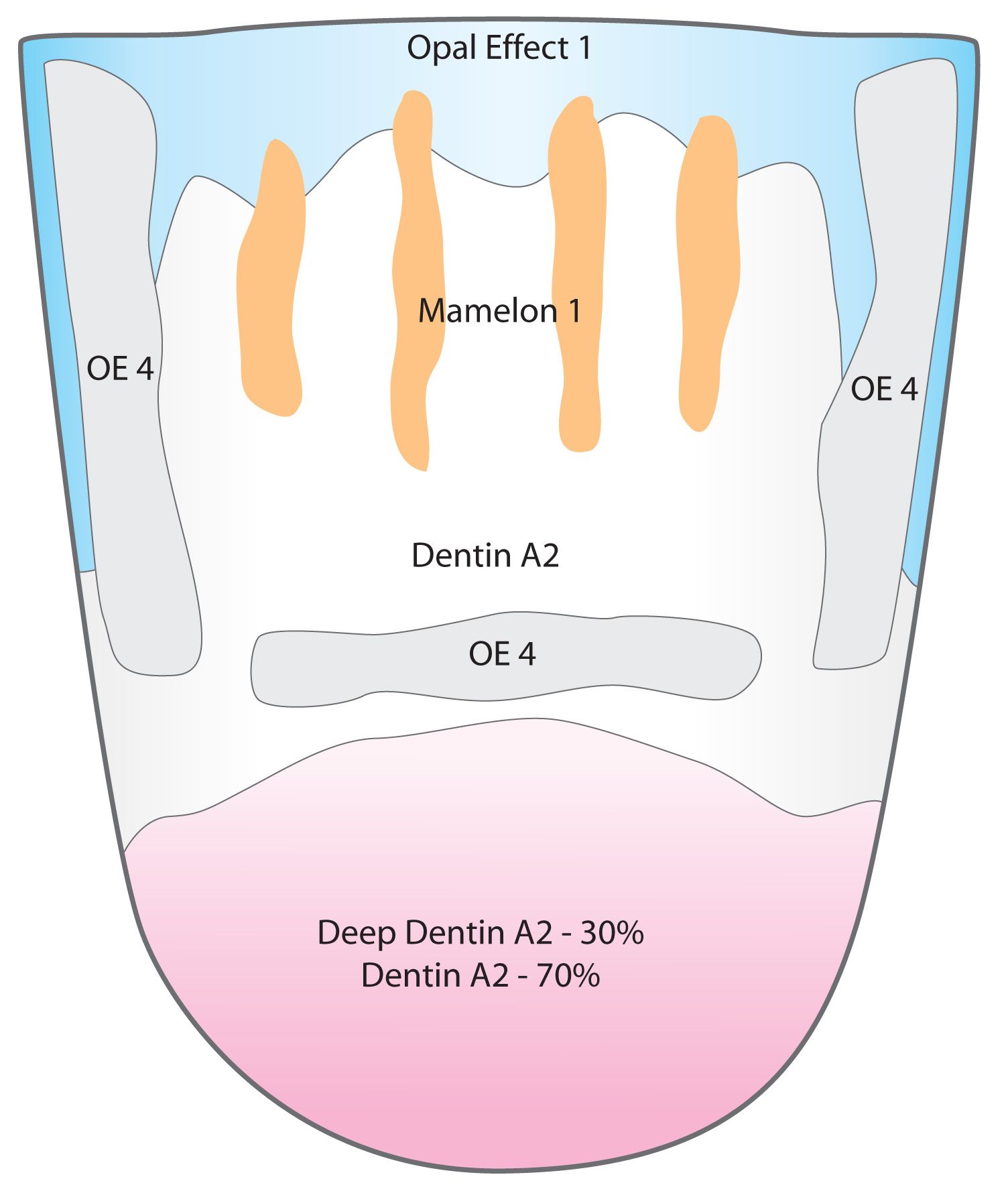

02 The alloy coping was opaqued using the InLine Paste Opaque Deep Dentine 30% and Dentine 70% Color A2 as base shade. Mamelon 1, EO1, and TI 1 –TI2 were also applied, and a first firing conducted.

03 Shade OE1 enamels and modifiers were applied, and shade OE4 was used for the middle third and the distal and mesial line angles to create a frame to increase the high value in those areas.

04 Shade CT yellow, plus a combination of OE4 and T-neutral, were then applied.

05 Crack line white and vanilla were applied to the restoration to create the calcification effects that appear on the natural tooth.

06 Finally, rotary tools were used to achieve the restoration’s final luster and texture (Figs. 8a + 8b).

Figs. 8a + 8b Different views of the final IPS InLine Restorations.

Conclusion

Laboratory ceramists strive to fabricate esthetic combinations of metal and metal-ceramic restorations. In cases requiring PFM restorations, achieving a harmonious appearance with the natural dentition can be achieved by using a combination of Protocol Alloy and IPS InLine ceramic. Doing so can make the process easier, more predictable, and more productive, while simultaneously producing lifelike esthetics.