How to adjust and polish full-contour zirconia crowns using Komet USA's LD0707 system

"The LD0707 proprietary system from Komet USA offers the instruments necessary for adjusting occlusion and reconfiguring the luster of zirconia restorations."

"The LD0707 proprietary system from Komet USA offers the instruments necessary for adjusting occlusion and reconfiguring the luster of zirconia restorations."

Within the practice of restorative dentistry, all-ceramic restorations are quickly becoming the preferred choice of patients, dental laboratories and practitioners alike. The use of zirconium dioxide, in particular, has grown rapidly, making it one of the primary options often presented to patients. Many within the dental community view zirconia as the ultimate restorative material, offering a superb combination of strength, durability, biocompatibility and esthetics. Interestingly, although it is considered a ceramic, zirconia is a metal oxide exhibiting different properties from true ceramic materials currently in use, and it is harder and stronger than most metals used for crown and bridge procedures.¹ As such, it can be exceptionally difficult to adjust appropriately with standard instrumentation.

For the best results when working with zirconia, users should rely on instruments optimized for the high-strength material. Standard instruments often fail in these cases, requiring the operator to use multiple burs to adjust or polish a single restoration. In turn, if the instrumentation does not achieve a high luster on the restoration, the zirconia will be very unforgiving and antagonistic to the opposing dentition; therefore, a kit dedicated to high-strength ceramics offers the ideal solution. The LD0707 proprietary system from Komet USA offers the instruments necessary for adjusting occlusion and reconfiguring the luster of zirconia restorations.

The kit contains a range of specialized instruments engineered to cut, finish and polish full-contour restorations fabricated of zirconium oxide, lithium disilicate, aluminum oxide and other pressed ceramics. The kit provides four ZR Flash Polishers™ and three ZR™ Diamonds, all conveniently organized and secured in a stainless steel, sterilizable bur block. These instruments feature distinct polishing and cutting characteristics that address the unique material properties of today’s generation of high-strength dental restoratives.

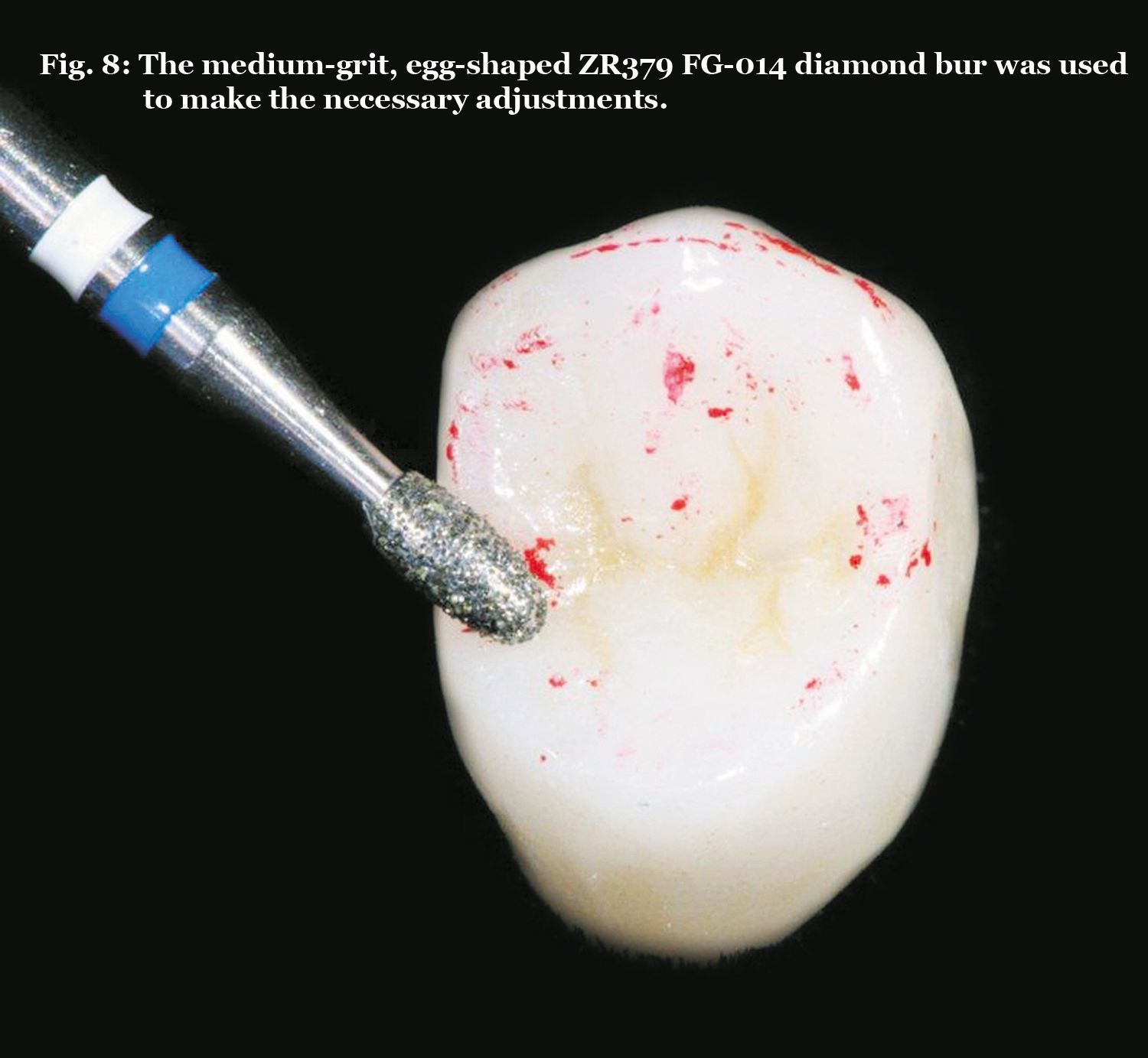

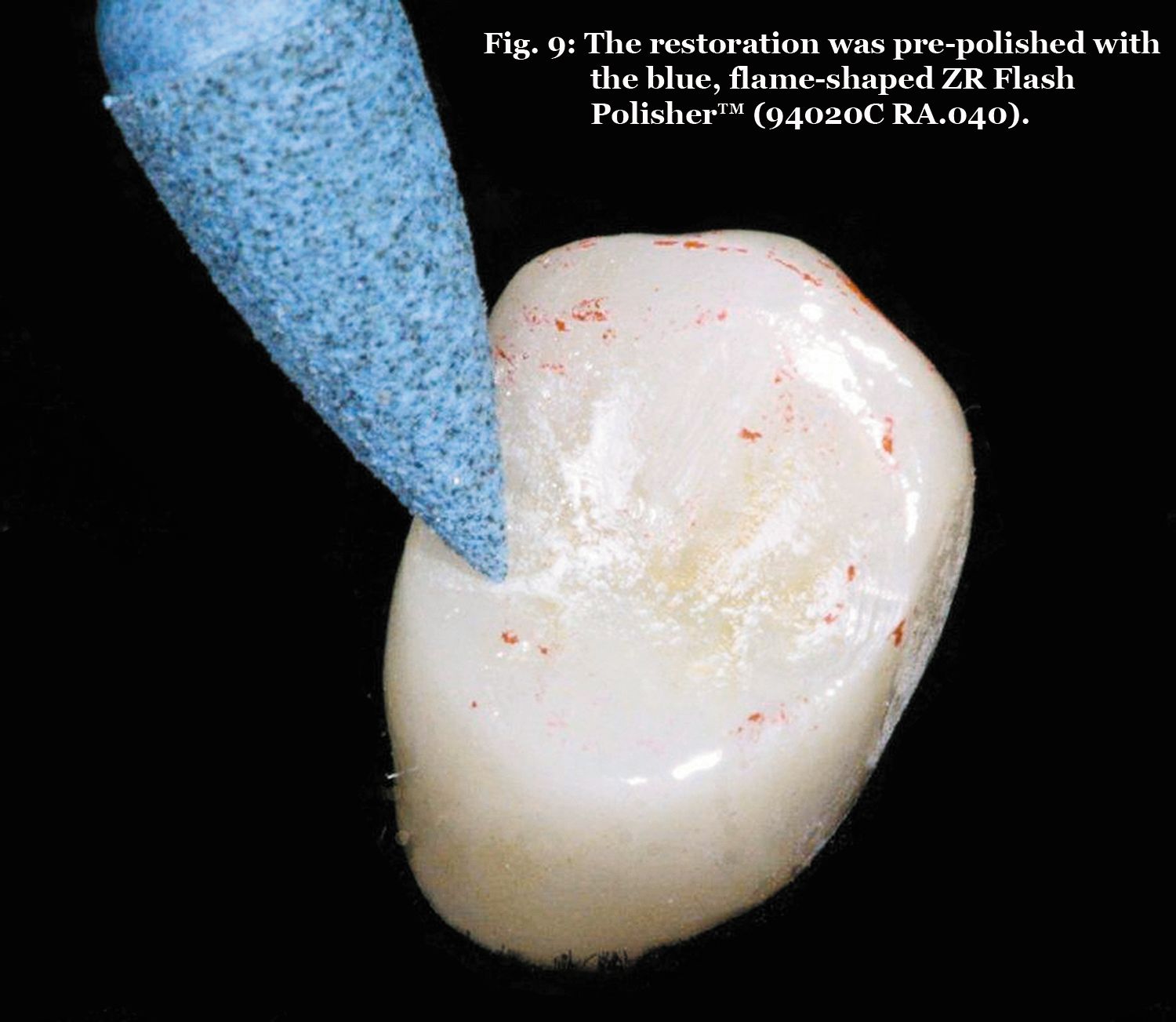

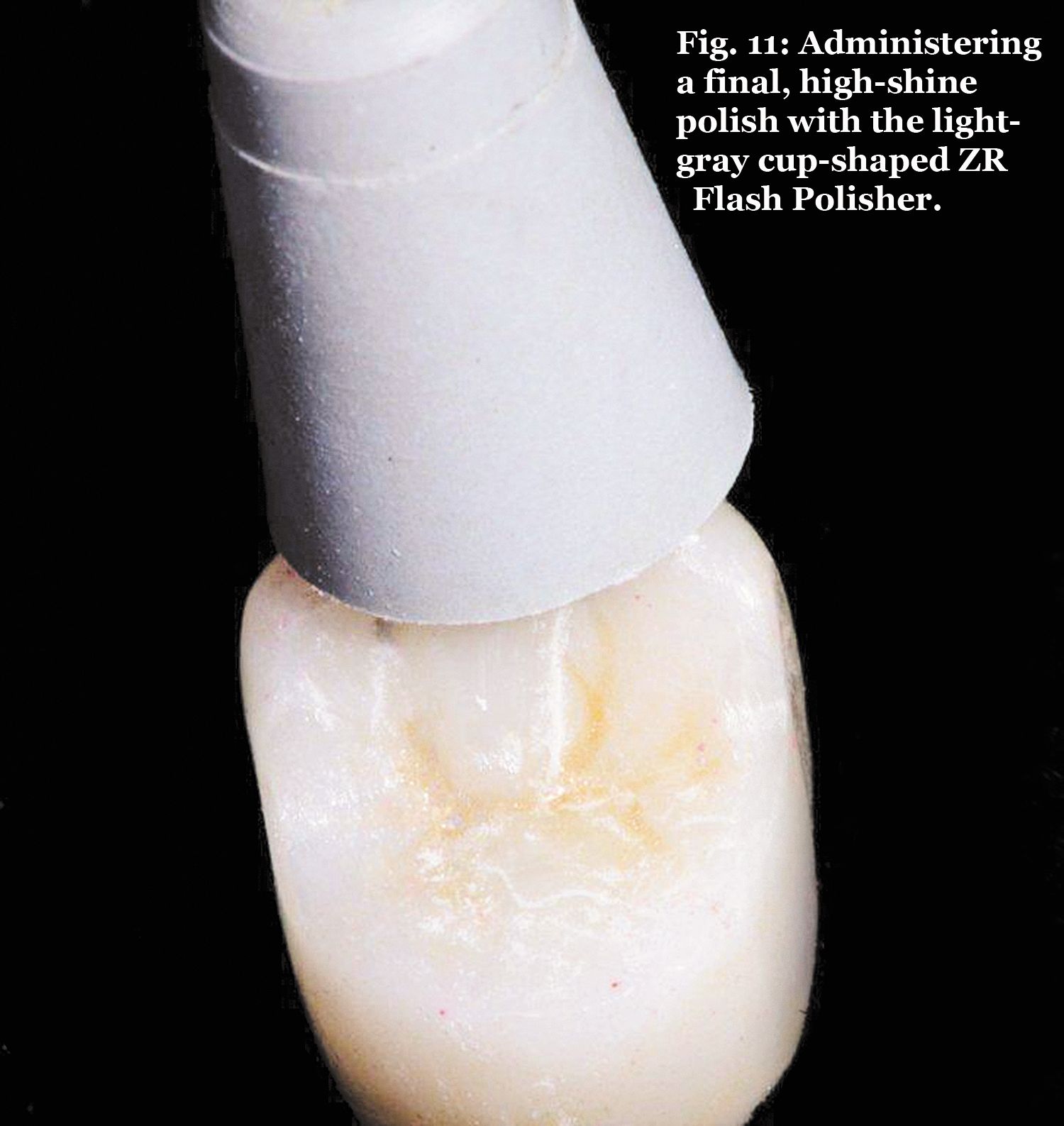

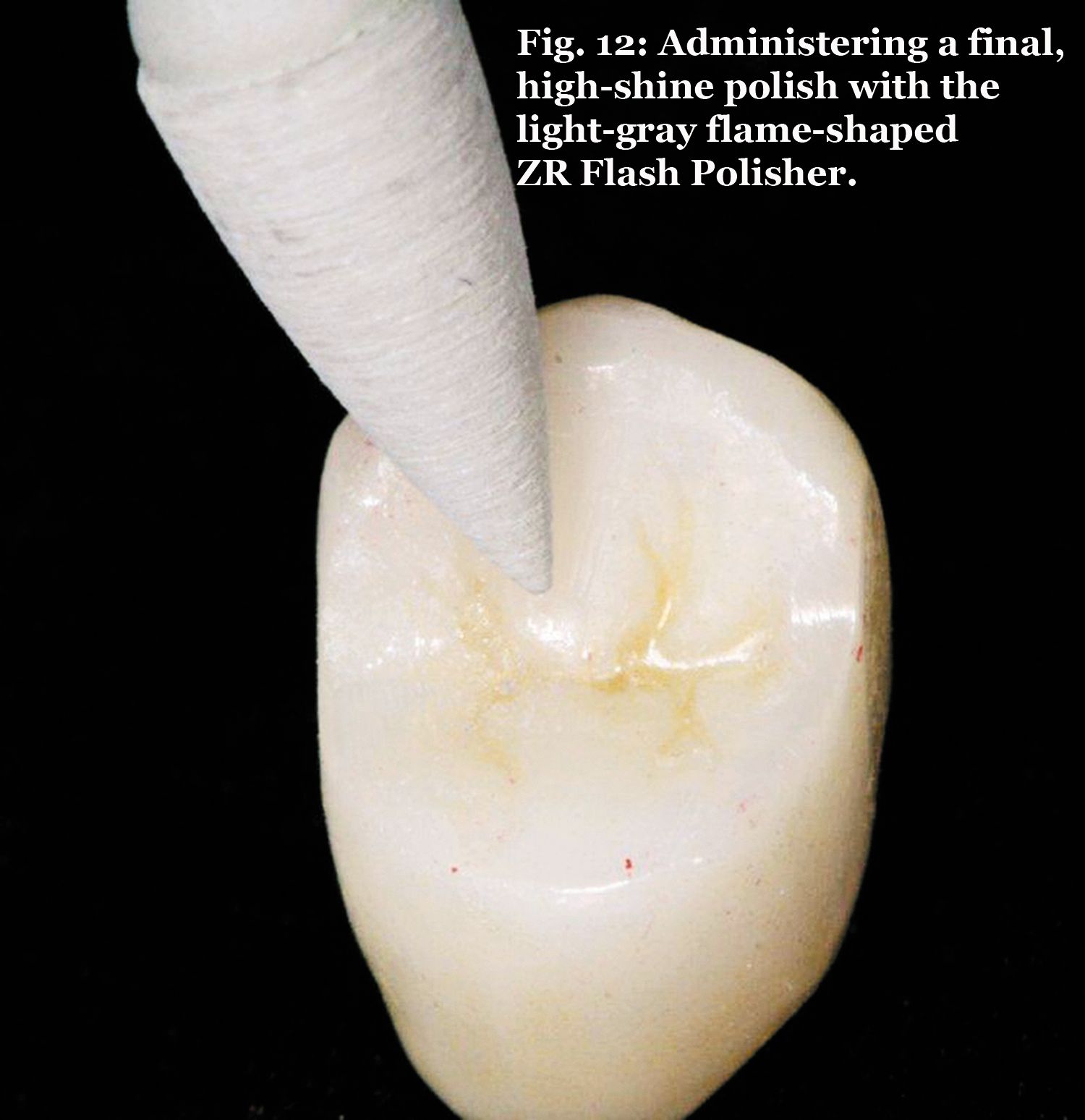

To re-contour, adjust or finish a zirconia crown, the ZR™ Diamonds are uniquely engineered with a permanently bonded, densely packed diamond layer. The coarse-grit diamonds provide an exceptional performance-to-service life ratio, and the medium-grit versions are especially suitable for a wide range of adjustment procedures. For preliminary and final polishing procedures, the ZR Flash Polishers™ smooth, polish and impart a high shine to zirconia in just two steps. The blue polisher is used for smoothing and pre-polishing, and the light gray polisher is used for high-shine final polishing.

The following case demonstrates the placement of a full-contour zirconia crown using the LD0707 Cut, Finish and Polish kit from Komet USA.

Case Presentation

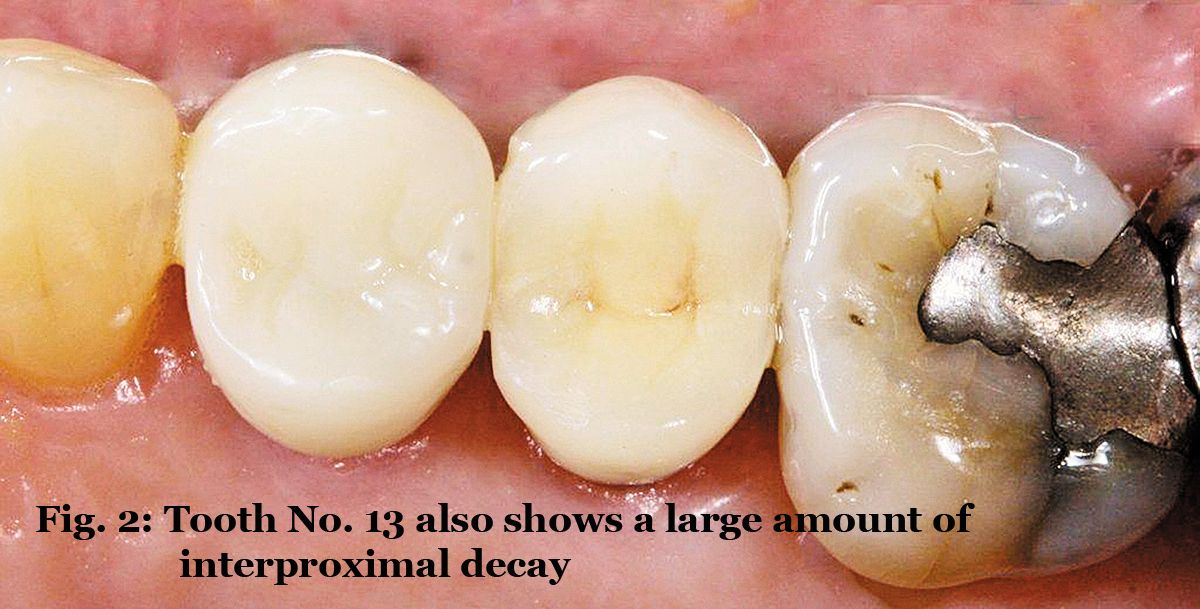

Step 1: The patient presented with a failing, 15-year-old PFM restoration on tooth No. 13. The tooth also exhibited a large amount of interproximal decay (Figs. 1 & 2 - click to enlarge image).

Step 2: Following injection of local anesthetic, the failing restoration was removed.

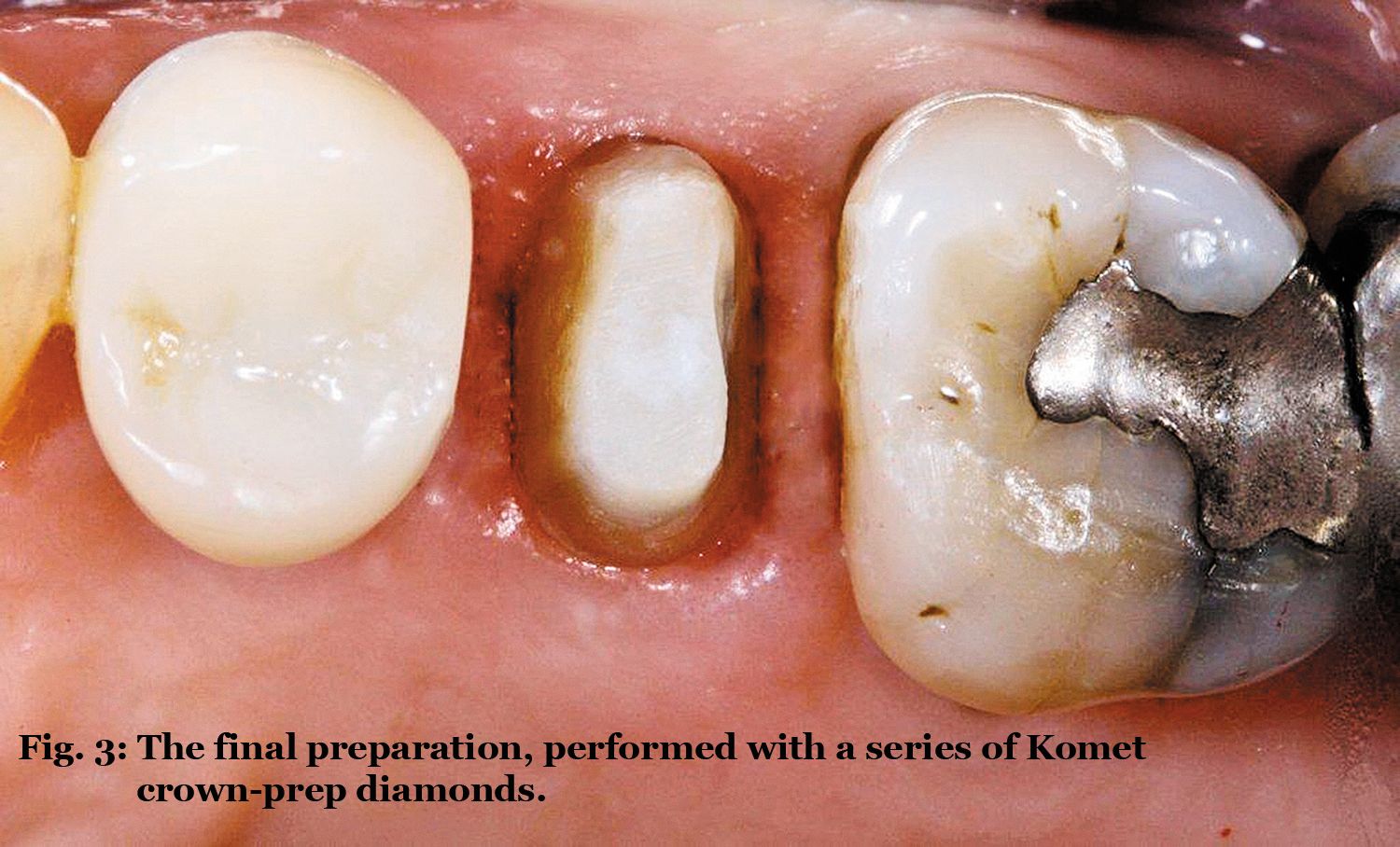

Step 3: The tooth was prepared using a series of Komet crown-prep diamonds, including the KS0, KS1SC and the KS3SC. Proper margins were established, and an antimicrobial scrub was applied to the preparation. The area was then thoroughly rinsed and dried. Figure 3 shows the final preparation (click to enlarge image).

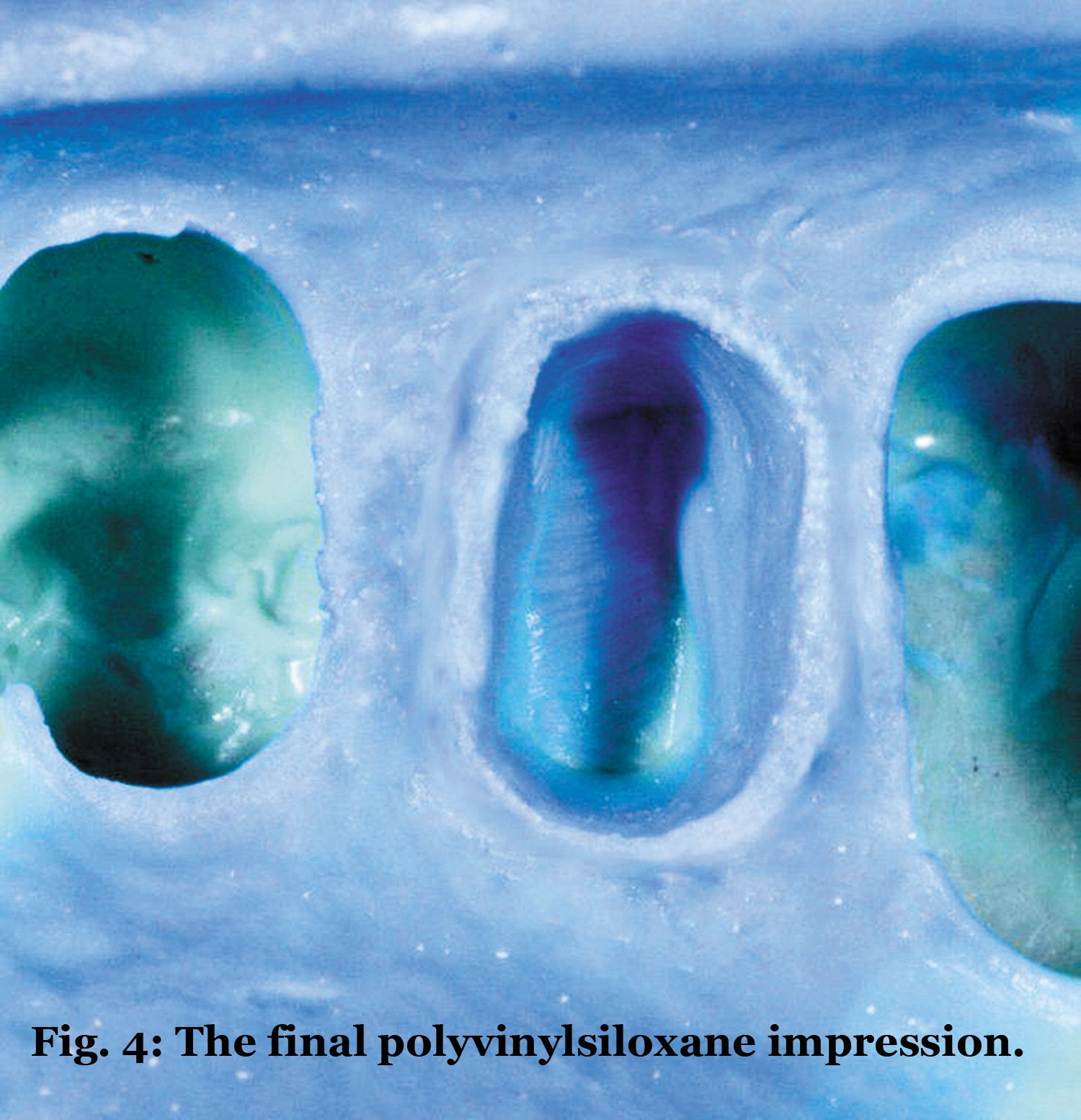

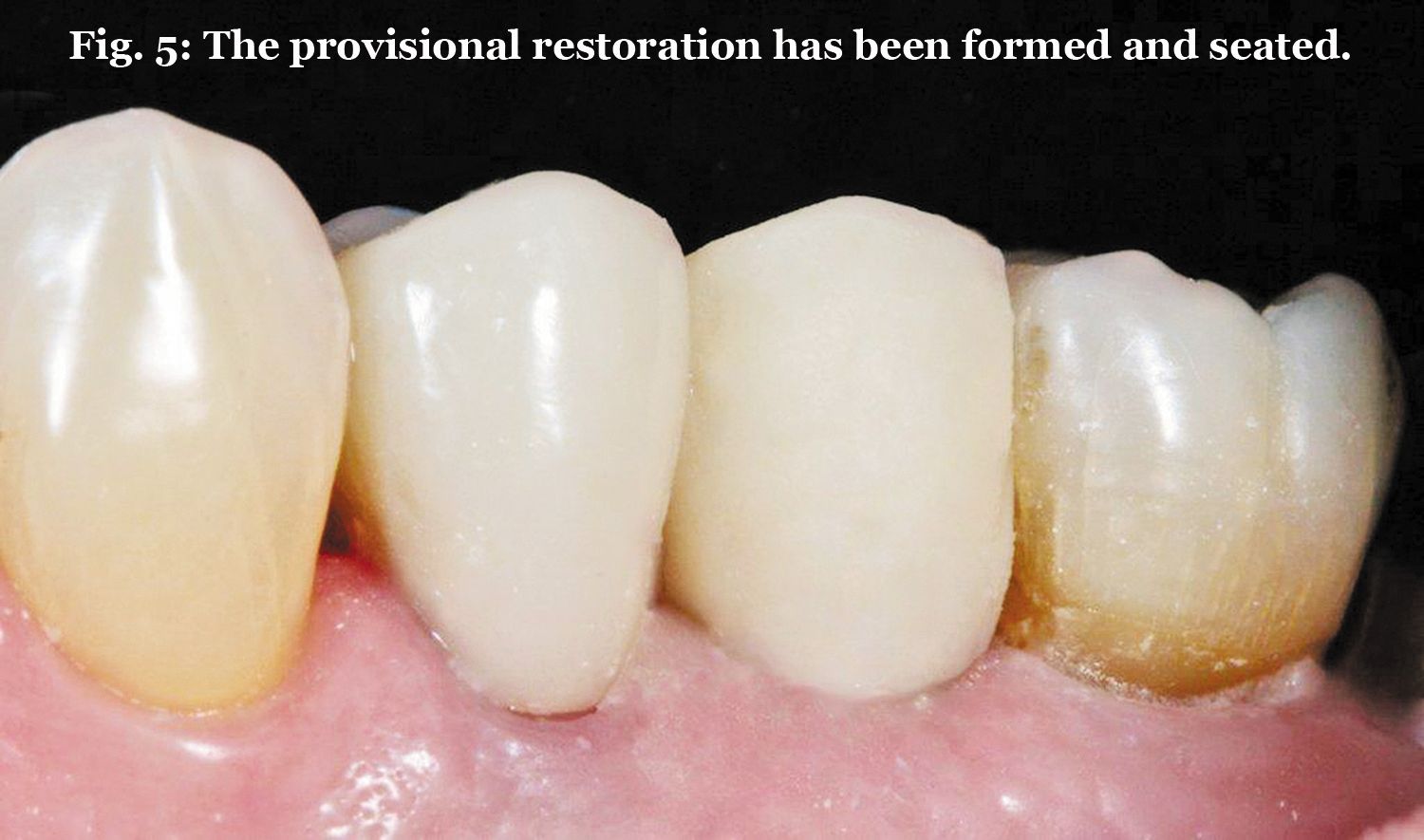

Step 4: A final polyvinylsiloxane impression was taken (Fig. 4 - click to enlarge image), and a provisional restoration was formed and seated (Fig. 5 - click to enlarge image). The patient received hygiene instructions for provisional care, and instructions were sent to the laboratory for creation of the full-contour zirconia crown.

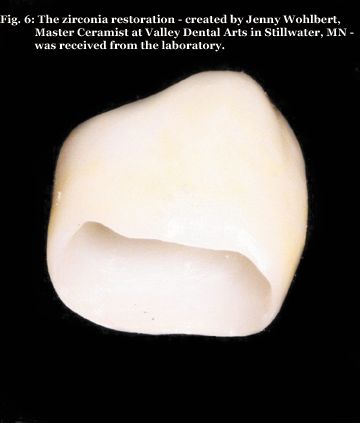

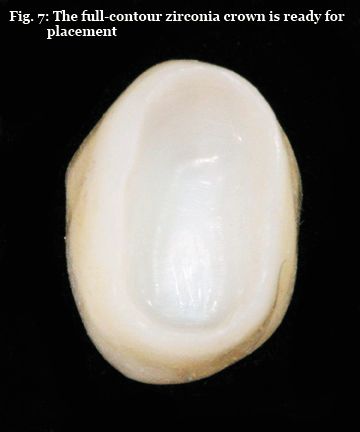

Step 5: The zirconia restoration was received from the laboratory (Figs. 6 & 7 - click images to enlarge). Note: All lab work in this case was created by Master Ceramist Jenny Wohlberg of Valley Dental Arts in Stillwater, Minn.; valleydentalarts.com.

Step 6: The crown was tried in, and articulating paper was used to determine spots that required adjusting. The medium-grit, egg-shaped ZR379 FG-014 diamond bur was used to make the necessary adjustments (Fig. 8 - click image to enlarge).

Step 7: Following adjustments, the crown was seated using Shofu’s BeautiCem SA self-adhesive resin cement.

Step 8: The restoration was pre-polished with the blue, flame-shaped ZR Flash Polisher™ (94020C RA.040) (Fig. 9 - click image to enlarge).

Step 9: Figure 10 demonstrates the finish achieved with the pre-polisher.

Step 10: The final, high-shine polish was achieved with the light-gray flame and cup-shaped ZR Flash Polishers™ (Figs. 11 & 12).

Step 11: The final finish demonstrated optimal luster, showing the zirconia has been polished to an ideal finish (Fig. 13).

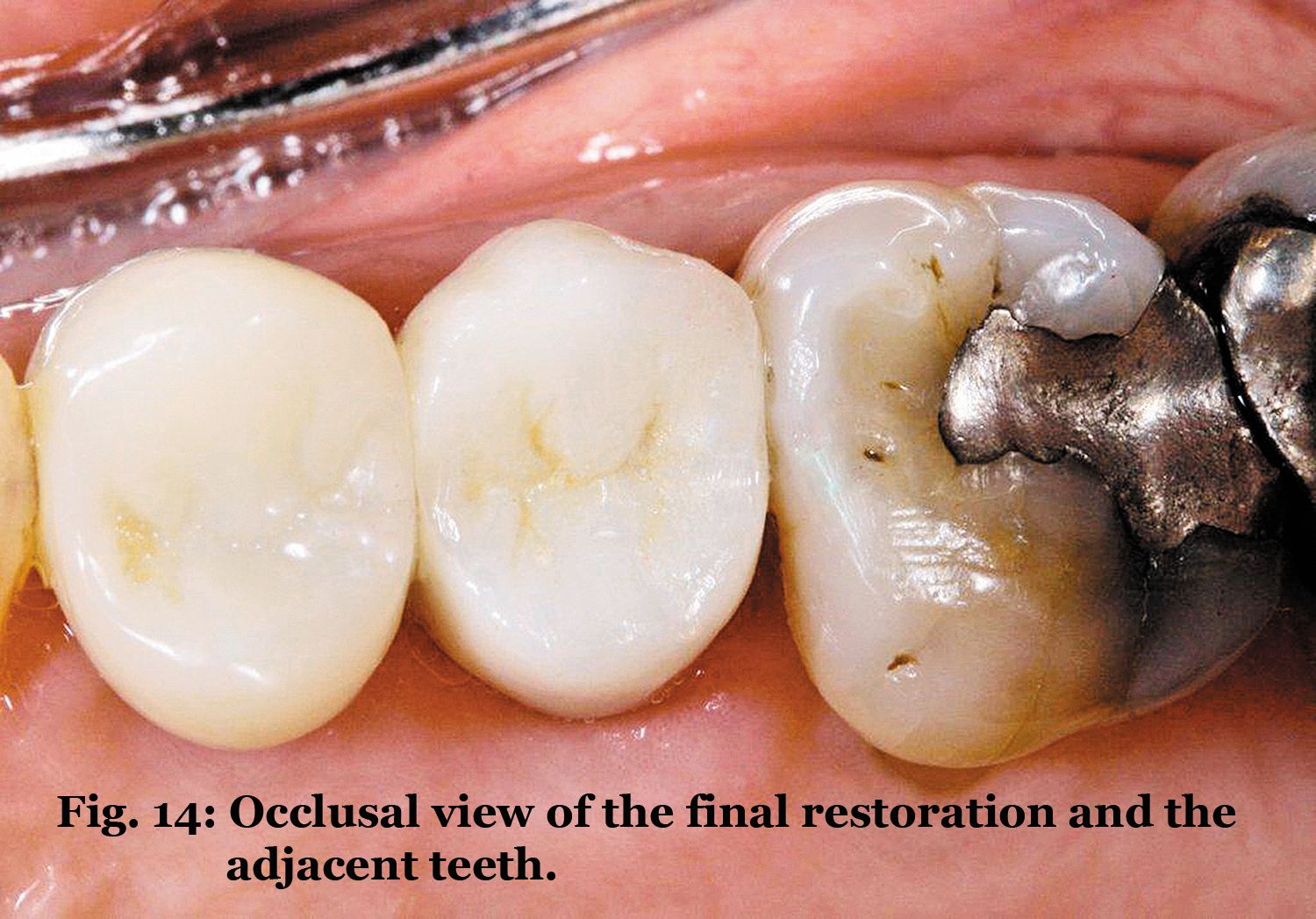

Step 12: The post-operative occlusal and buccal views (Figs. 14 & 15) demonstrated an ideal match between the restoration and the adjacent teeth. Form, function and esthetics were restored.

Closing thought

Today’s aspiring clinicians benefit from gaining an understanding of the biomaterials that are used in modern restorative dentistry. By understanding how the materials are fabricated and how they can be adjusted, we are better able to select the right instrument for a given material. Dedicated systems such as the Komet® LD0707 Cut, Finish and Polish kit enable us to better serve our patients and, in turn, the practice of dentistry as a whole. This simple, dedicated system allows us to logically and predictably adjust high-strength ceramic restorations at chairside, helping clinicians to remain in step with advances in material science.

1 Helvey G., Finishing zirconia chairside. Inside Dentistry. 2011;2(2):38-48.

Komet USA LD0707 Cut, Finish and Polish Kit Features

- Designed to polish, cut and finish full-contour restorations, including those made of zirconia, lithium disilicate and other pressed ceramics

- Includes four ZR® Flash Polishers and three ZR® Diamonds

- Each kit comes with a sterilizable, stainless steel bur block

Komet USA

kometusa.com 888-566-3887

ACTIVA BioACTIVE Bulk Flow Marks Pulpdent’s First Major Product Release in 4 Years

December 12th 2024Next-generation bulk-fill dental restorative raises the standard of care for bulk-fill procedures by providing natural remineralization support, while also overcoming current bulk-fill limitations.