A 3D look at the future: A roundup of dental 3D printers

A 3D look at the future

Perhaps there is no better example of smart technology in the dental profession than the introduction of 3D printing. Initially embraced by dental laboratories, more and more practices are adopting this technology for in-office use. With its cost-savings, efficiency, and immediacy, it’s clear to see why. Plus, 3D printing is suitable for a range of applications, including crown and bridge models; clear aligner models; splints and nightguards; and even full dentures. Just as 3D printers fabricate these objects layer-by-layer, these machines can add an additional layer of services to dental practices. Imagine delivering full dentures or a sleep appliance to your patients in days versus weeks-that’s smart.

Read on for an overview of 3D printers.

Continue reading on the next page...

Structo Velox

- An all-in-one desktop 3D printer with built-in autonomous post-processing features

- Print, wash, and cure appliances at the push of a button for same-day dentistry

- Integration with digital design services providers, enabling users to go straight from intraoral scan to printed appliance

- Designed for chairside use to maximize time

Structo

877-787-8286 | structo3d.com

NextDent® 5100

- Powered by Figure 4® technology, facilitating high-speed 3D printing

- Suitable for fabricating crowns, bridges, surgical guides, orthodontic splints, and trays with precision

- Compatible with intraoral scanning and software solutions

- Designed to produce devices at speeds up to 4x faster, while reducing waste and reliance on milling centers, enabling up to 90 percent cost savings

3D Systems

888-598-1438 |

3dsystems.com/3d-printers/nextdent-5100

Continue reading on the next page...

Stratasys J720

- An all-in-one 3D printer that can print realistic models using 500,000 color combinations

- The large-capacity PolyJet machine is designed to access six materials at once

- Sized at 490 x 390 x 200 mm, it has a maximum capacity of 200 µm

- Can print in full color using materials that mimic the shape, texture, and color of teeth and gums

- Uses GrabCAD Print software, which can create a gcode directly from the CAD model without the need to convert files

Stratasys

800-801-6491 | stratasys.com/dental

Sprintray Pro Desktop

- Features a large build platform of 18 x 10 cm while still maintaining its desktop form factor

- Touchscreen controls and contextual instructions managed by a 6-core CPU

- Print jobs can be started from the USB port

- Ability to print up to 30 full-arch dental models in a single batch

- The custom 405 nm, LED 95 μm projector provides high-intensity light evenly across the build surface for an accurate print

- Unique resin certification system enables the use of materials from a variety of other brands

Sprintray

800-914-8004 | sprintray.com

Continue reading on the next page...

caraPrint 4.0

- A 3D-DLP printer that produces monochrome dental appliances using a high-quality photopolymer

- With an X&Y resolution of 53.6 µm, it has the ability to deliver precise restorations faster and more economically

- Its user-friendly interface for both beginners and experienced CAD/CAM users

- Most indications print within one-hour or less

- Together with Kulzer’s dima® Print materials, followed by post-curing in the HiLite® Power 3D, ensures high-quality results

Kulzer

800-431-1785 | kulzerus.com/cara

Form 3B

- Advanced Low Force Stereolithography (LFS)™ technology uses a flexible resin tank and a custom-designed, user-replaceable Light Processing Unit to produce consistent prints

- Features an XY resolution of 25 µm, and a build volume of 14.5 x 14.5 x 18.5 cm, designed to print 2-3 times more parts

- Production environments see 55 percent less labor time and costs

- Switch between a library of dental resins with a no-hassle cartridge system

Formlabs

617-702-8476 | dental.formlabs.com

Continue reading on the next page...

Envision One cDLM

- A desktop printer designed for dental and orthodontic applications

- Capable of printing six orthodontic arch models in under 15 minutes

- Features a high-resolution industrial projector with UV glass

- LED light source at 385 nm for higher accuracy on clear parts and crisper details on all parts

- Dual linear slides provide stability during build process, eliminating shifting parts

- Domeless technology delivers high accuracy in Z

EnvisionTEC

313-436-4300 | envisiontec.com

EvoDent S110

- Compatible with multiple materials as the resin tank can be changed without leveling

- Open system design - all STL files are available

- Features a UV LED light source, 40 mm/h, and has USB, ethernet, and Wi-Fi connectivity

- Capable of a broad range of applications, including veneers, inlays/onlays, temporaries, surgical guides, ortho models, splints, and removable partial dentures

EvoDent

770-881-8299 | evodent3d.com

Continue reading on the next page...

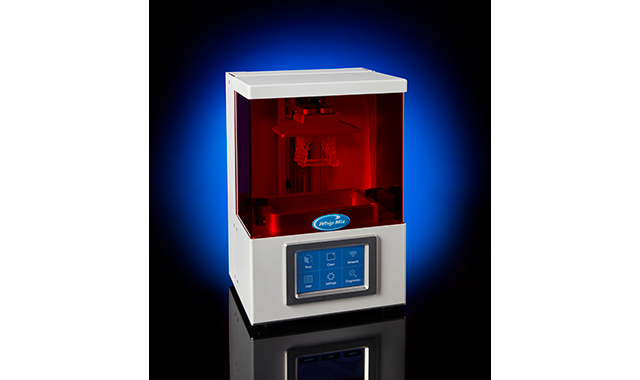

VeriBuild LCD

- This open system printer is able to print 405 nm print resins using the proper file

- Prints accurate surgical guides with slice thicknesses between 25-100 µm

- Its build volume is 118 x 66 x 140 mm and has a high pixel resolution of 47 µm

- Qualified for use with these VeriBuild resins: OS Ivory, OS Golden Brown, OS White, OS Grey, and OS Surgical Guide Resin

Whip Mix

502-637-1451 | whipmix.com

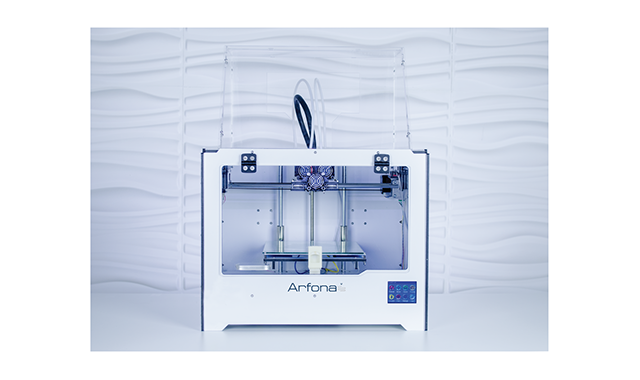

r.Pod®

- Powered by Fused Filament Fabrication, technology that takes a thermoplastic wire (filament) and feeds it through a hot nozzle, where it is melted and deposited layer by layer into a 3D object

- Eliminates the need for photopolymers, resulting in stronger, longer-lasting restorations with no monomers

- Enables users to print with a variety of thermoplastics, including Valpast®

- Capable of multi-material printing for parts with removable support material and multicolor printing

- Applications include dentures and appliances, custom impression trays, study models, and soft tissue gingiva

Arfona

718-290-9300 | arfona.com

Continue reading on the next page...

Carbon M2

- Uses Carbon’s Digital Light Synthesis technology, which is said to be approximately 20 times faster than traditional DLP/SLA techniques

- Over the air software updates

- Features a 189 x 119 x 326 mm build volume for low-volume dental labs

- Open and compatible with any STL file

- Prints typically with +/- 50 um

Carbon

650-285-6307 | carbon3d.com

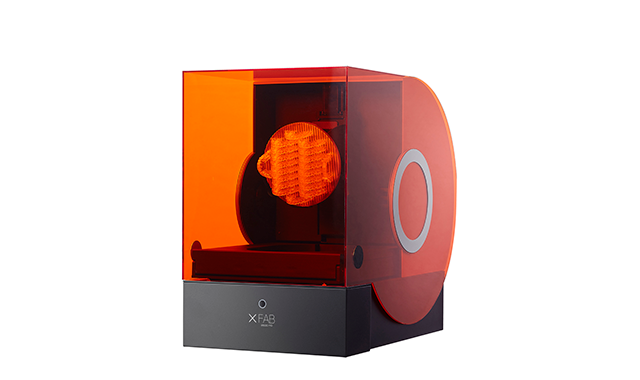

XFAB 2500 PD

- This desktop printer features a “plug and play” USB connection, and a cylindrical work area of 180 x 180 mm

- Specifically designed for small to medium dental labs, it’s provided with Nauta and Fictor software with the possibility to manually set the customized parameters of DWS materials

- Compatible with five materials for dentistry from DWS

- Features a BluEdge® proprietary laser, parametric technology, and automatic heating system and material temperature control

DWS Systems

info@dwssystems.com | dwssystems.com

Continue reading on the next page...

Micron P305

- A desktop printer that employs the use of new masked LCD light engine technology that allows for a larger build area without sacrificing accuracy and speed

- Capable of printing 12-24 arches per run as fast as 10 minutes per arch

- A 100 percent open solution option

- Features a 7.5” x 4.7” build plate, a high contrast 2K LCD, and a UV LED light source

- One-click Wi-FI print from any device

Micron Dental

844-448-6008 | microndental.com

Ackuray A135

- Provides a build envelop of 135 x 76 x 130 mm

- Print speeds up to 4 cm/hr

- Open material system

- Prints detailed appliance +/- 25 µm to +/- 35 µm

- Ability to print with any SLA/DLP resin

Ackuretta

support@ackuretta.com | Ackuretta.com

A 3D printer for every need

3D printers spur end-to-end digital dentistry. Using a light or laser, these printers polymerize a liquid with computer-guided precision. The two most commonly used 3D printer technologies in dentistry are stereolithography (SLA) and digital light processing (DLP). While both rely on light to cure a photosensitive resin, there are a few key differences.

SLA

Dating back to the 1980s, SLA is one of the oldest forms of 3D printing. Using a laser, its concentrated light photopolymerizes resin monomers in a given section. The laser moves across a vat of resin and the layer is drawn according to specifications in order to build the 3D object.

DLP

A technique developed in the late 1980s, DLP projects each layer, creating a plane where photopolymerization will occur. Unlike SLA, where light is directed to a single spot, DLP forms the whole layer at once. Patterning of the desired shape is done using a “mask” produced by a digital micromirror device (DMD). The DMD can be replaced by LCD screens in some models. More modern DLPs use LED as a light source.

Information gathered from all3dp.com.