DPR Exclusive Materials Survey: Your guide to the latest in dental materials

There are many great dental restorative products and impression materials available, and DPR’s latest survey indicates most of you are very satisfied with your choices.

There are many great dental restorative products and impression materials available, and DPR’s latest survey indicates most of you are very satisfied with the choices.

The tricky part, however, comes when trying to decide when or if to switch materials and which materials will deliver on their promises and allow you to continue producing long-lasting restorations that will keep your patients smiling.

You want to reach for a material you can count on. But how do you know if the latest generation offering is right for you? And how can anyone stay on top of all these terms being tossed around?

It isn’t easy at all, but we hope to help here by sharing advice from educators and manufacturers, and also by taking a look at what our readers think about all things materials.

How do you know if it’s time to try a new material and who do you trust to help you make these decisions? Well, Dental Products Report attempts to be a great source for informing clinicians of all the new product offerings and also a great resource for how-to technique articles and videos of how best to use those materials.

But just how important is it for you to actually understand all of the terms surrounding today’s materials, and just how important is it to follow all the directions that come with the various materials and the curing lights used to activate those materials?

With the help of several experts, we hope to get you on the right track to understanding all of the latest and greatest dental materials. This latest DPR Exclusive Survey on Dental Materials is designed to let you know more about the latest materials, the science behind them, the terminology that can help you make purchasing decisions, and who can help you the most while incorporating these products into your practice.

“There are many descriptive terms used to categorize materials for convenience. Dentists should know what these words mean and how they impact the physical properties of the materials,” said Dr. Daniel Ward, an author and lecturer who is in private practice in Columbus, Ohio.

“The reality is there are major differences between different products. Most manufacturers understand that they must provide educational information about their materials, and many have online technique videos about their particular products.”

In the survey, we asked our readers about how well they understood a variety of terms including nanofilled hybrid, micro-hybrid, hydrophillic, thixotropic, dual-cure, total-etch, and more.

An example of the confusion out there today is reflected by the fact that only 68% said they have a knowledgeable understanding of the term thixotropic, while just more than three-fourths understand the term microhybrid well enough to make practical purchasing decisions.

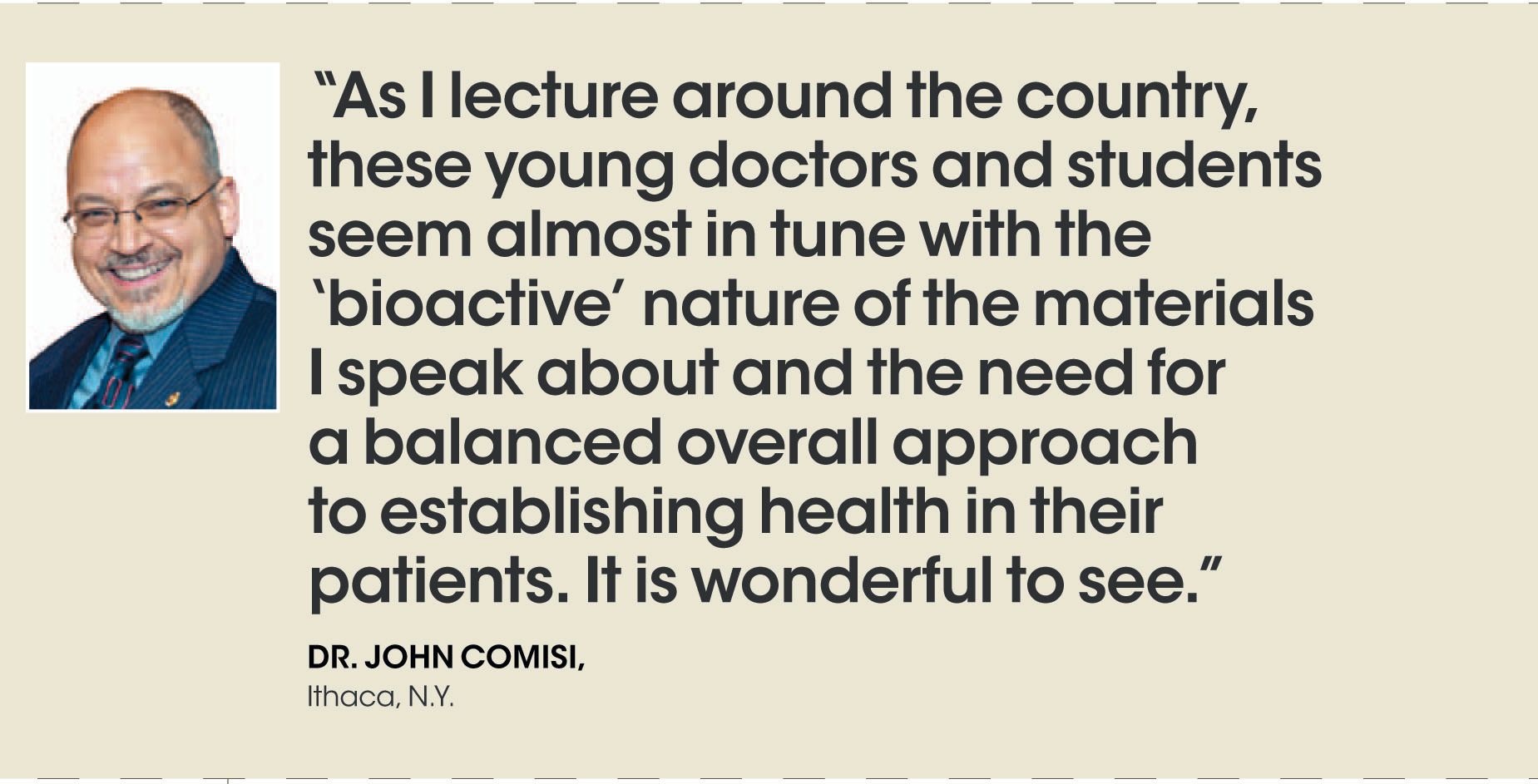

Dr. John Comisi, DDS , MAGD , lecturer, author and member of The Catapult Group who has a private practice in Ithaca, N.Y., said it’s important to understand the terms and the science around today’s materials.

“It is crucial for clinicians to understand these various terms simply because using the wrong material in the wrong place intraorally will increase the odds of failure of the restorative process,” he said. “As doctors, the impetus is on us to know and understand why one type of material or technique would work best in the conditions and places that we are working. Otherwise, we fail our patients and our profession.”

Dr. Robert Lowe, who lectures on cosmetic dentistry and materials, said there are a variety of resources available to dentists looking to stay educated on dental materials. It’s critical to know what you want your dental products to do before making a materials choice.

“Read dental journals, attend lectures on current materials and techniques, be involved with study clubs, and most of all, talk to your colleagues!” Dr. Lowe suggested.

“And THE most important factor in deciding a material to use is choosing what is best for that particular patient or case. Too many doctors want ‘a magic bullet’ that works for all clinical situations. What is the health of the gingival tissues? How good is the patient’s home care? How important is esthetics? Does the patient clinch or grind ... are they ‘hard’ on their teeth? All of these parameters are important to consider before choosing the dental restorative material that best fits the patient’s functional and esthetic needs.”

Dr. George Tysowsky, Ivoclar Vivadent’s Vice President of Research & Development, acknowledges there is a lot out there for clinicians to try to stay on top of, but adds that they should determine their needs and then do some research to decide which products best meet those needs.

“Continuous developments and release of new materials is taking the field of dentistry to a new era. With the recent advances in adhesives (universal bonding agents), composites (bulkfill resin composites), CAD /CAM (CEREC OmniCam, 4.2 software, E4D Technologies), blocks (e.max, VITA, Lava Ultimate), it is becoming a challenge for a dentist to judge the best material as per his/her needs,” Dr. Tysowsky said.

“This question can be answered well if a clinician defines his/her needs, understands the advantages and limitations of a dental product, and makes clinical decisions accordingly.”

To do so, he said, a dentist’s clinical judgment along with the basic understanding of materials science and chemical composition could significantly improve the efficiency and the clinical outcome. For example, dental composites are made from various size filler particles (macrofilled, microfilled, nanofilled, hybrids), resin matrix, and other components like photoinitiators, modifiers, and pigments.

All these components contribute significantly to the physio-mechanical properties of dental composites. Microfilled composites attain high polished surface whereas macrofilled composites are not very polishable and wear easily. On the other hand, hybrid composites attain advantages of both micro-filled and macrofilled composites, which give high wear resistance, high poshilability, low polymerization shrinkage, and better handling.

“Similarly, the other questions which I encounter very often are the difference between light-cure, dual-cure, and self-cure resin cements and their indications,” Dr. Tysowsky said.

“Ivoclar Vivadent, being one of the fastest growing dental manufacturers, considers the dental industry as a delicate chain of trust from researchers to educators, manufacturers, laboratories, dentists, and patients. And like all other chains, we contribute by building on a foundation of sound research and development platforms, long-term clinical data, and support the fundamentals that have always been the part of dentistry, education, and quality tested products.”

Ivoclar Vivadent considers it its own responsibility to educate clinicians about products by providing scientific tools like detailed instructions for use, white papers, smartphone apps, and by organizing lunch-n-learns, webinars, focus groups, and CE courses.

Many materials manufacturers invest significantly in research and development prior to launching new products, but then also make sure expert technicians, clinicians and researchers are on hand should customers have questions or need assistance while selecting a dental product that best serves their clinical needs.

Tooth-colored materials

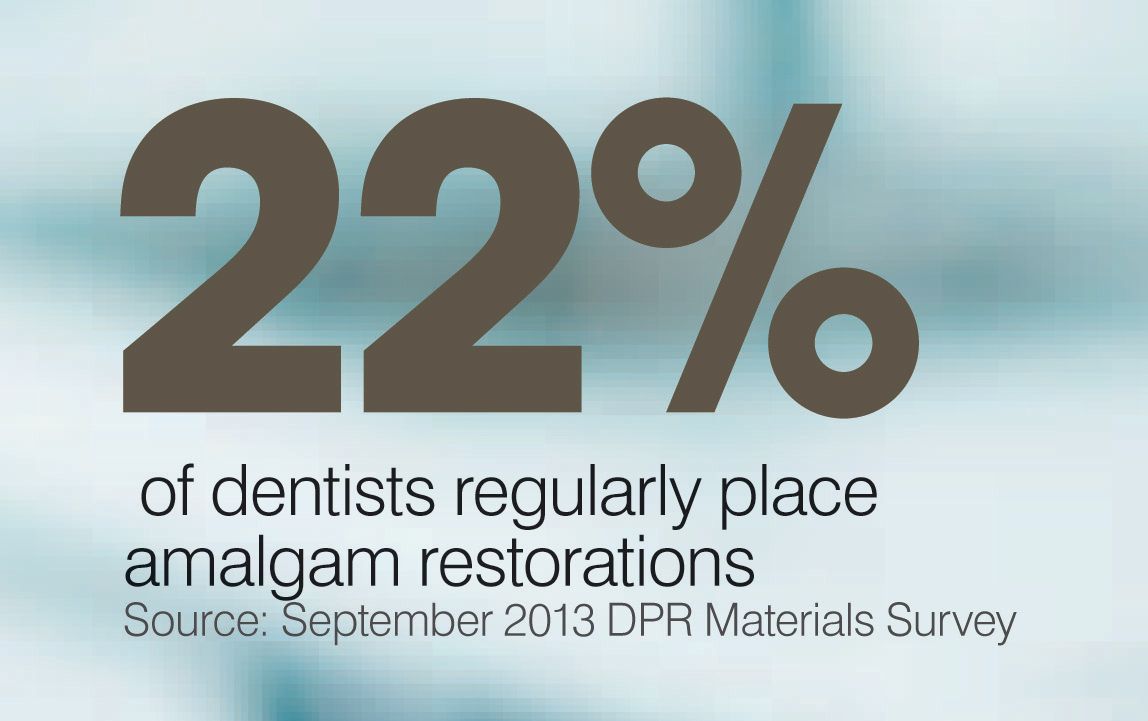

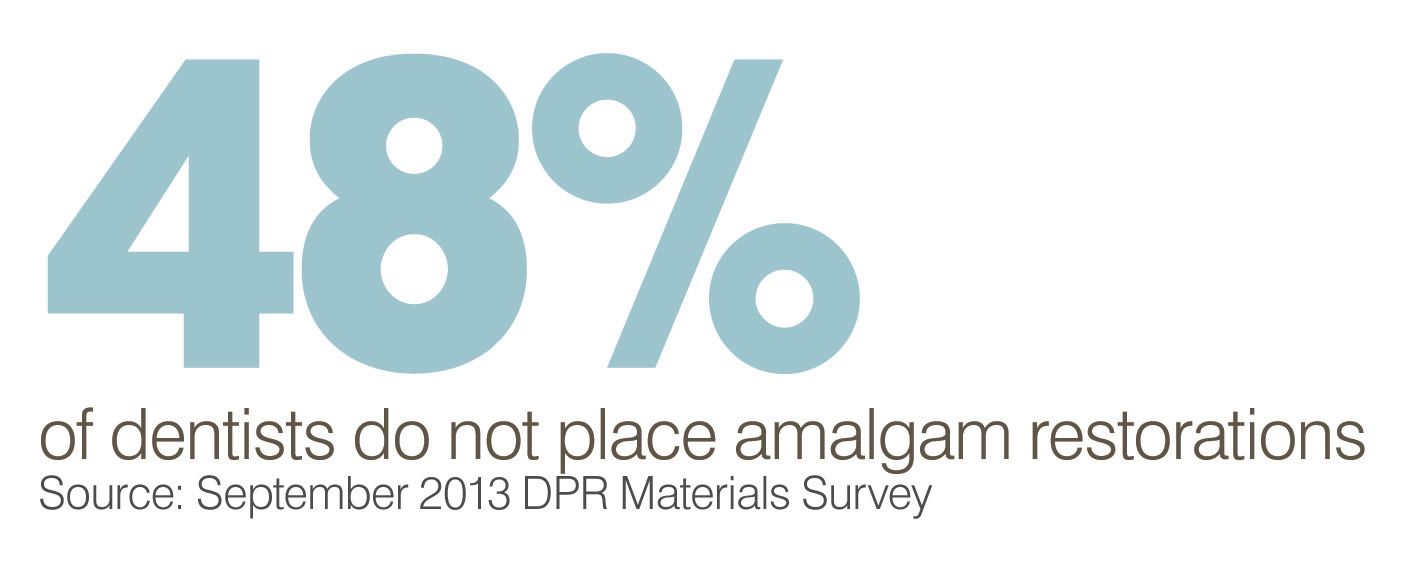

With tooth-colored materials a staple in most practices these days, we asked dentists what they felt about them in terms of how long they’ve used them, their satisfaction with the available choices, and what might influence them to try another brand.

Most of the survey respondents have used tooth-colored direct restorative systems/materials for some time now, and most are quite content with the results.

When we asked about direct restorative systems/materials dentists use most frequently, 39% said they have been using them for more than 5 years, while another 37% said between 2 to 5 years. And when we asked them to rank their overall satisfaction with the current products in this category -with 5 meaning very satisfied and 1 not satisfied at all - 29% chose 5, and 59% chose 4, while only 1% of the respondents said they were not satisfied at all.

Dr. Lowe was not surprised and noted that today’s material options provide clinicians with a number of good choices.

“Tooth-colored restorative materials, or composite resins, continue to improve. Today the trend is toward adhesive systems and composites that are easier to use (less technique sensitive), yet not sacrificing good clinical results,” Dr. Lowe said. “Examples are ‘universal bonding agents’ and ‘bulk fill materials.’

“In selecting direct restorative materials for clinical use, ease of use, predictability, reliability, and fewer clinical steps without compromising clinical result are important factors. The ‘ultimate,’ I think, will be when we have a composite that has zero shrinkage, does not need a bonding agent, (ie. is ‘self adhesive’), and is moisture tolerant, like amalgam.”

Dr. Ward agrees that today’s busy dentists want materials that are not difficult to use and are not overly technique sensitive.

“The No. 1 factor I hear from clinicians is that they want something that is easy to use and not technique sensitive,” he said. “Consistent results are important. Bonding agents are a prime example. The new universal bonding agents are designed to give excellent results with self-etch and total-etch, self-cured and light-cured, and direct and indirect techniques. In larger offices with multiple assistants, it is important that materials perform well when used by different personnel with their individual nuances.”

Dr. Comisi said it’s important for dentists to get some hands-on training with new materials so they can know firsthand what works best for them.

“First off, the clinician needs to know what differentiates this material or technique from others. Are there specific characteristics that make it more suitable for use? Where is it indicated and where is it contraindicated,” Dr. Comisi said.

“The best way to educate doctors is with a combination of the science of what and why this material or technique is different or better, and hands-on working with the material or technique. This can be done either ‘live’ or on interactive webinars with hands-on components.”

Dr. Tysowsky said it’s also important to keep the role of the dental laboratory and the patient high on the totem pole of importance.

“I strongly believe that the formula for a dentist’s success is clear - combine the new materials and techniques (used in conjunction with quality, traditional materials) along with a new partnering relationship with laboratory technicians, manufacturers and communicate these options to the patient,” he said.

The Ivoclar Vivadent VP of R&D admits that staying on top of the ever-evolving field of products is not always easy, but is indeed an important factor for today’s clinicians.

“Dentists are abreast with new materials and technologies, however, because of factors such as limited time to review scientific information or clinical data, limited exposure to hands-on, or lack of trust of new products, makes many clinicians hesitant to adopt new materials,” he said.

“That being said, manufacturers innovate new products to meet not only clinicians’ but also patients’ needs and expectations. Most of the manufacturers introduce these products after intense scientific evaluation with both invitro and invivo testing to provide a confidence that their materials will perform as intended.”

While finding the time and resources to learn everything about several new products may be a real obstacle for dentists, taking the time to follow the manufacturer instructions is not an area where they should take shortcuts.

“In order to achieve a best clinical outcome, it is important for a dentist to follow manufacturer’s instructions for use, indications, to understand clinical situations and to make clinical judgment accordingly,” Dr. Tysowsky.

“Each material has its advantages and limitations! No one material yet is indicated for all clinical situations, which makes it important for manufacturers to provide all scientific tools, educate clinicians and assist them further with their questions.’

“I believe scientific documentation, white papers, third-party evaluations, and clinical trials provided by manufacturers are excellent sources for dentists to review. Clinicians should appreciate all this information to educate themselves and should not hesitate to discuss further regarding new products with sales representatives, manufacturers or during focus groups, dental meetings or lunch and learns.”

Influencing factors

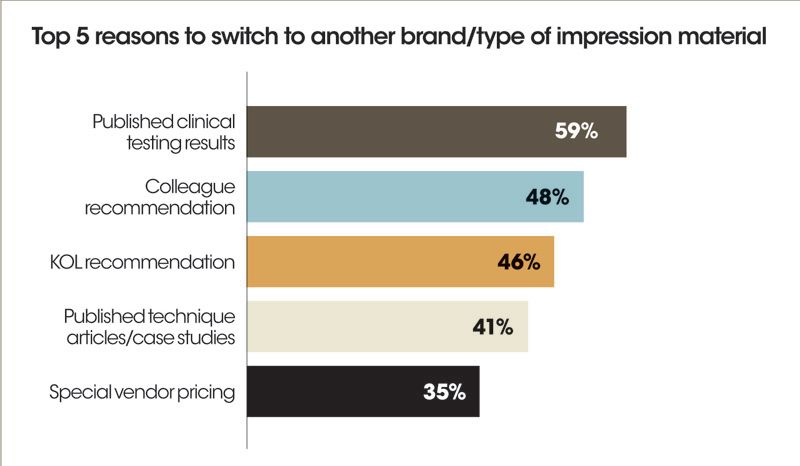

So what motivates you when considering to try a new brand or type of tooth-colored direct restorative system or material? We wanted to find out how just important KOLs, colleague recommendations and things like vendor pricing were, so we asked.

What we learned was that 67% of survey respondents said published clinical testing results would motivate them to switch brands, while just more than half are influenced by key opinion leaders (52%) and a colleague's recommendation (51%). Almost half (48%) indicated that published technique articles/case studies can motivate clinicians to try another material, while special vendor pricing sways 29%.

“Dentists need to be wise consumers and do their homework,” advised Dr. Ward, who served as Assistant Clinical Professor at The Ohio State University for 13 years. “Obviously reading publications is important to staying current on the latest materials and trends. Attending meetings with hands-on courses are invaluable ways to not only learn about, but practice using materials under expert supervision and guidance.”

Are improvements needed?

While the satisfaction levels are quite high for today’s materials, there are areas where you would like to see things improved, with longevity leading the way. We asked what single aspect of the current esthetic direct restorative process you think needs the most improvement, and restoration longevity was the No. 1 response, coming in at 37%.

The next highest response came from just 13% who suggested handling (placement and sculpting) needs the most improvement. But that small percentage figure reflects that, for the most part, today’s clinicians are content with the available restorative materials.

Dr. Comisi said clinicians today do want their materials to speed up the restorative process, which is why bulk fill materials have become quite popular recently.

“Bulk fill materials are all the rage right now. The doctors want it quick and easy,” Dr. Comisi said. “‘Get it done’ is the feeling. There are some excellent materials available and some very nice delivery units as well.

"However, these materials although low in shrinkage, still possess shrinkage stress and will ultimately create challenges to the restorative process since this stress will create micro leakage and ultimate failure. Bonding agents that reduce or eliminate shrinkage stress, like SDI ’s Riva Bond LC, will become quite popular and important in the near future, in my opinion.”

Impression materials

There have been a number of innovative impression materials released lately, including a trio of launches on the cover of this month’s issue of DPR. Even so, many clinicians have remained quite loyal to the material they currently use most often.

Half of the survey respondents have used the impression material they use most frequently for more than 5 years now, while another 32% have stuck with their choice for 2 to 5 years.

Seven percent of the survey respondents have been going with their most frequently used impression material for one year or less. And when it comes to impression materials, our readers seem just as happy with the choices currently available.

Again, on a 1 to 5 scale, 39% selected 5 (very satisfied) and 51% checked No. 4. Only 1% of the respondents were not satisfied at all with the impression materials currently available.

In other results

Some other interesting results from the survey included the following stats:

• 38% of the respondents have been using their most frequently used bonding agent system/material for more than 5 years.

• Slightly more than one-third of the respondents (34%) indicated that between 16-30% of their overall operating budget goes to materials-related expense.

ACTIVA BioACTIVE Bulk Flow Marks Pulpdent’s First Major Product Release in 4 Years

December 12th 2024Next-generation bulk-fill dental restorative raises the standard of care for bulk-fill procedures by providing natural remineralization support, while also overcoming current bulk-fill limitations.