How to achieve long-term clinical success with Celtra advanced glass ceramic

Examining the microstructure of Celtra and how it leads to long-term clinical success.

There are a large number of materials to choose from for ceramic restorations. Feldspathic-based materials have been used for many years now for veneers, inlays and onlays.

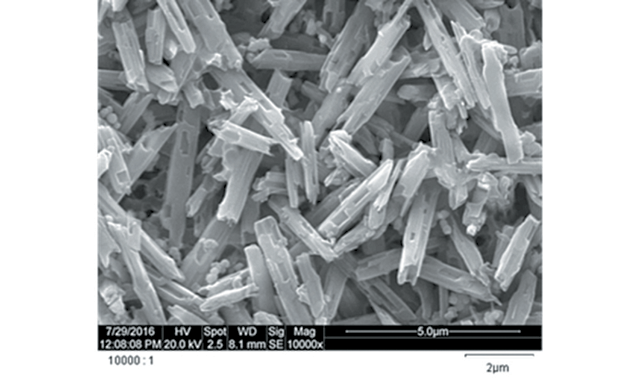

Fig. 1

Mechanical properties are low, with flexural strength typically varying from 70-100 MPa. With the introduction of glass ceramics, such as lithium disilicate, mechanical properties increased greatly and indications for use have expanded to full contour restorations throughout the mouth. These materials have approximately 70 percent crystal structure composed primarily of lithium disilicate crystals (Fig. 1).

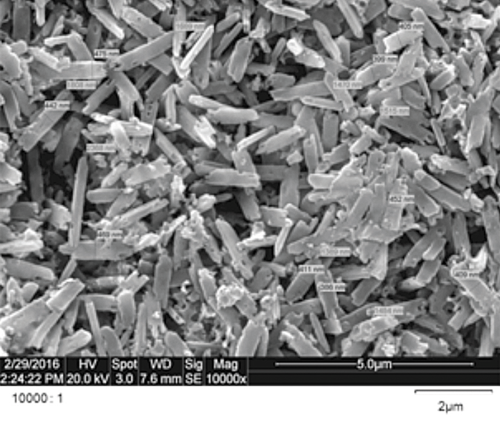

Development of glass ceramics has continued to further improve properties by refining crystal structure. The innovations in Celtra, Celtra Duo and Celtra Press (the newest pressable version of Celtra created for dental laboratories) relate back to the microstructure of this material. It is a 10 percent zirconia-reinforced lithium silicate glass ceramic. The lithium silicate material has 70 percent dissolved particles of zirconia that help decrease mean crystal size down to about 1.5 microns, with even finer submicron crystals in between these larger ones (Fig. 2).

Related reading: Using Celtra Press in your lab

In creating dental materials, we seek to find materials that resist crack growth. In general, as the crystal size decreases and content increases, the resistance to fracture increases. Hopefully, our restorations behave like natural teeth that can sustain damage but also successfully exist for years without failure. Flexural strength is only one component to consider when selecting materials.

Fig. 2

There are a number of other important properties to contemplate for a given clinical case. Fracture resistance, color stability, polishability/gloss, margin integrity and creation of a smooth “wear-kind” surface free of subsurface defects. Color stability and a chameleon effect are also very important from an esthetic standpoint. How does the Celtra fulfill these requirements? And with so many glass ceramics available, what makes the Celtra family of materials so unique?

Trending article: 5 techniques showcasing long-lasting results

Unique properties of Celtra materials

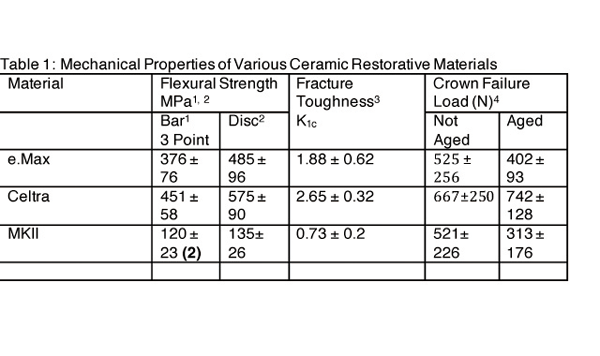

One of the principal concerns with using ceramic materials is their ability to resist stress in the mouth. There are a number of methods to examine this, including flexural strength, fracture toughness and failure load of actual crowns.1-4 Although Celtra is a relatively new material, there has been research examining these various areas. The mechanical properties of glass ceramics were tested using different methods according to ISO Standard 6872, fracture toughness and load to failure of maxillary incisor crowns (Table 1).

The overall conclusion from this is that the refined microstructure of Celtra appears to improve properties in all categories important to long-term clinical success. Of particular importance is toughness and load to failure of actual crowns. Although bar and disc testing are helpful in evaluation, testing of crown failure resistance as used clinically is extremely important. Celtra was very resistant to aging, indicating a good resistance to the stresses of oral activity over time.

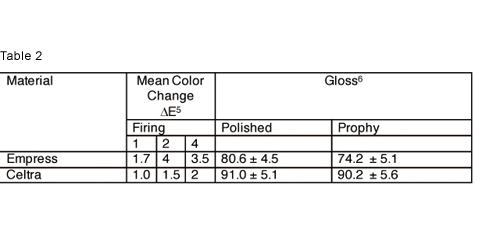

An important issue in shade matching is the color stability upon firing of finished restorations. Often it is necessary to apply additional colorants (stains) to get the best match to the patient’s teeth adjacent to the restorations. One problem with glass ceramics, or any ceramic, is to maintain both the structure and color upon repeated firings.

Related reading: How to create strong restorations with Celtra Press ceramics

Initial examination of color stability of two glass ceramics is shown in Table 2. Color is measured with a spectrophotometer to determine the values in color space: value, red-green and blue-yellow. An equation is used to determine the position in color space called ΔE. Color testing has shown that a value of ΔE of 2-4 can usually be seen by most people as a clinically obvious difference in color.5 The table also shows gloss, measured of polished restorations and those subjected to prophy that occurs routinely when patients come for recall to visit the hygienist.6 Celtra maintains the color over repeated firings.

In addition, a pressable version of Celtra has recently been introduced exclusively for laboratories called Celtra Press. Celtra Press has all the same durable and esthetically pleasing properties that Celtra Duo possesses.

Conclusion

Ceramic materials are in widespread use with a myriad of choices. Material selection is designed to maximize the esthetic and longevity of that restoration for the patient. The novel Celtra glass ceramic is demonstrated to show improved mechanical and physical properties that should enhance our ability to provide a reliable long-term positive clinical outcome for our patients.

References

1. Wear, strength, modulus and hardness of CAD/CAM restorative materials Nathaniel C. Lawsona, Ritika Bansalb, John O. Burgess Dental Materials 32(2016 ) e275–e283.

2. Giordano, R Flexural strength of ceramic materials, in progress, 9/2017.

3. Alternative loading approach for compact tension test, Dental Materials, Volume 32, Issue 7, 2016, Pages 847-852.

4. Fracture resistance of glazed, full-contour ZLS incisor crowns, Franz Sebastian Schwindling, Stefan Rues, Marc Schmitter, Journal of Prosthodontic Research, Volume 61, Issue 3, 2017, Pages 344-349.

5. Giordano, R Effect of repeated firing on color stability of ceramics, in progress, 9/2017.

6. Effect of professional dental prophylaxis on the surface gloss and roughness of restorative materials. Sugiyama T, Kameyama A, Enokuchi T, Haruyama A, Chiba A, Sugiyama S, Hosaka M, Takahashi T J Clin Exp Dent. 2017 Jun 1;9(6):e772-e778e283.

ACTIVA BioACTIVE Bulk Flow Marks Pulpdent’s First Major Product Release in 4 Years

December 12th 2024Next-generation bulk-fill dental restorative raises the standard of care for bulk-fill procedures by providing natural remineralization support, while also overcoming current bulk-fill limitations.