vhf camfacture AG and Ivoclar Further Strengthen Partnership

With second Ivoclar certification in past year, vhf is now an official Ivoclar Authorized Milling Partner for the renowned lithium disilicate ceramic IPS e.max CAD.

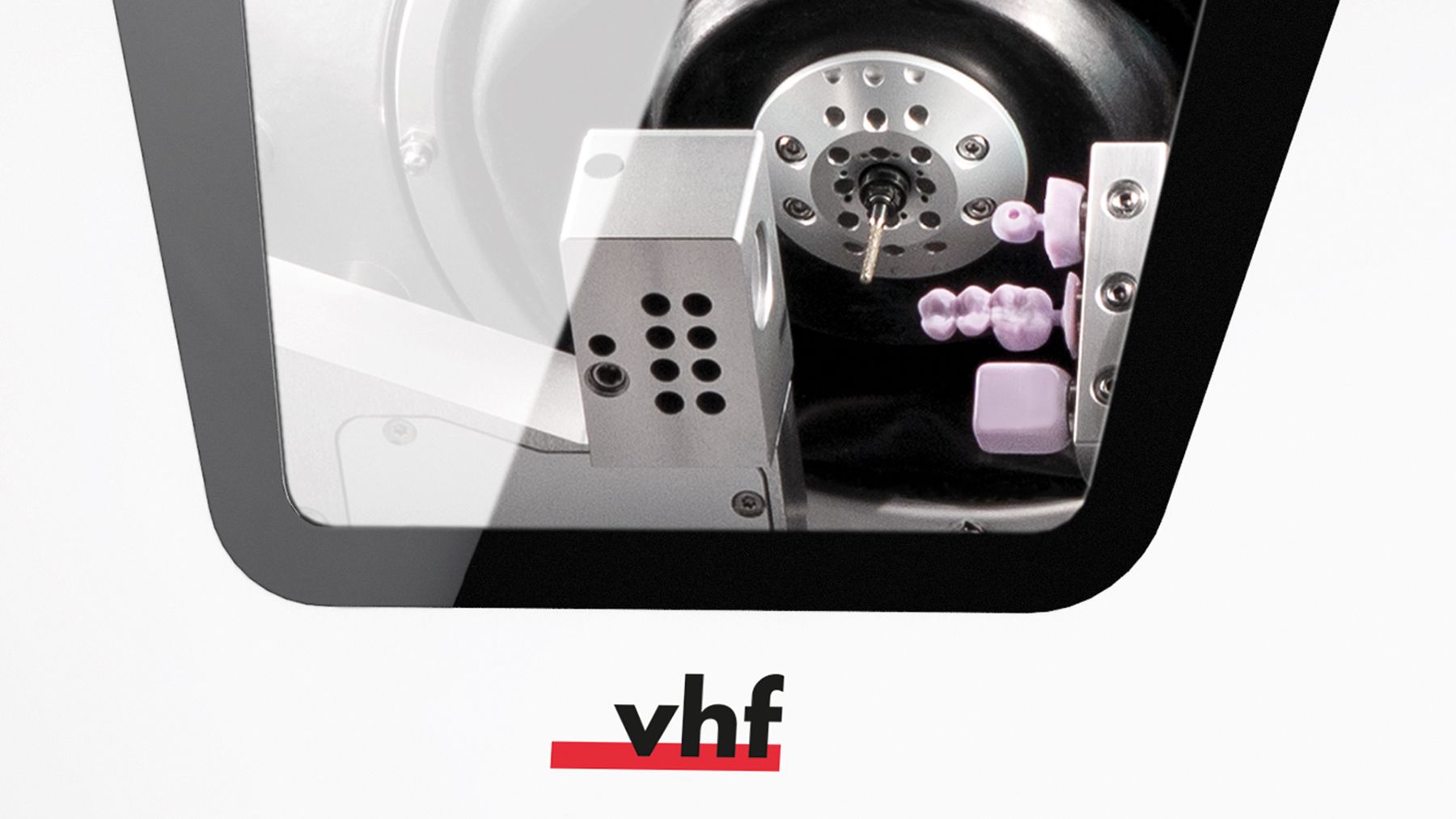

vhf camfacture AG and Ivoclar Further Strengthen Partnership | Image Credit: © vhf camfacture AG

Ivoclar has a long-standing collaboration with vhf camfacture AG and the partnership continues to strengthen following the announcement that vhf is now also an official Ivoclar Authorized Milling Partner for the renowned lithium disilicate ceramic IPS e.max CAD.

The IPS e.max Authorized Milling Partner accolade represents a validated and well coordinated processing procedure between the dental material and the milling device. The 2 companies state this seal of quality guarantees high-precision, high-quality restorations and has now been officially awarded to vhf.

The latest announcement comes after vhf was one of the first manufacturers to be certified as an Ivoclar Authorized Milling Partner for the Ivotion Denture System in February 2023. That collaboration was designed to offer customers maximum flexibility in designing and producing digital prosthetic solutions.

As part of the newest collaboration, the vhf DENTALCAM 8.09 software update will be available in mid-March 2024, and the IPS e.max CAD for PrograMill in the vhf N4+ will be authorized for crowns, inlays, onlays, veneers and 3-unit dental bridges up to the second premolar, the companies say. vhf also plans to obtain authorization from Ivoclar for additional wet grinding machines soon.

“The collaboration between vhf and Ivoclar to achieve a successful validation reinforces the trust and certainty of users in the quality and precision of the vhf dental milling machines. The IPS e.max Authorized Milling Partner accolade is the official declaration that dental and practice laboratories can process IPS e.max CAD in an optimal procedure with vhf machines,” says Lucas Kehl, head of product at vhf camfacture AG, in a press release.

Vhf, a leading manufacturer of modern dental milling machines, high-precision milling tools and associated CAM software, is well known internationally for its high standards of quality and the innovative strength of its products; 2 characteristics shared by vhf and Ivoclar. The N4+ machine is the top seller from the company’s vhf PERFORMANCE CLASS. The 4-axis wet grinding machine has served many dental laboratories and practices since 2020.

Earlier this year, vhf updated the N4+ and the dental milling machine now has a new machine design and the company reports that even the most demanding users are happy with the wet processing capabilities of the device.

“We are delighted to further expand our already very successful partnership with vhf. We share the high standards that we want to offer our customers at all times, along with the constant development of our products and workflows,” Stefan Schulz, director global business unit clinical prosthetics at Ivoclar, adds in the press release.

IPS e.max CAD has been a popular choice of dental technicians and clinicians for 2 decades. The clinically proven lithium disilicate glass ceramic material features a strength of 530 MPa,1 which Ivoclar states achieves impressive results with its natural color behavior and optimal light-optical properties. After the blocks are wet processed, the restorations are crystallized in a Programat furnace.

The vhf DENTALCAM 8.09 software update will be available in mid-March 2024, and the IPS e.max CAD for PrograMill in the vhf N4+ will be authorized for crowns, inlays, onlays,veneers and 3-unit dental bridges up to the second premolar. vhf is also planning to obtain authorization from Ivoclar for additional wet grinding machines soon.

The Ivoclar Group, headquartered in Schaan, Liechtenstein, is one of the world's leading manufacturers of integrated solutions for high-quality dental applications. vhf camfacture has its headquarters in Ammerbuch, Germany near Stuttgart.

ACTIVA BioACTIVE Bulk Flow Marks Pulpdent’s First Major Product Release in 4 Years

December 12th 2024Next-generation bulk-fill dental restorative raises the standard of care for bulk-fill procedures by providing natural remineralization support, while also overcoming current bulk-fill limitations.