Using The Oz and QDfx as water treatment options

How these two products from Toppen Dental can be used to sanitize a dental practice.

Infection control is one of the most important aspects of running a successful dental practice, but every practice knows that being successful in this area is largely reliant on how well staff members follow protocol. And even under the best circumstances, the dental office is never 100 percent sterile. Consider dental unit waterlines, which still contain some level of bacteria even just after a cleaning.

Chemically induced infection control has several weaknesses when it comes to water treatment. The first is that the bacteria isn’t killed immediately, giving it time to multiply. The second is that even if all but 0.01 percent of the bacteria in the line is destroyed, it doesn’t take long for the rest of it to replicate and exceed the 500 CFU/mL limit recommended by the Centers for Disease Control and Prevention (CDC).

An additional shortcoming is that chemicals kill free-floating bacteria, but they’re not effective at eliminating biofilm, a slimy film on the inside of water pipes and waterlines that stores and protects bacteria. Biofilm isn’t affected by flushing the waterlines, a daily procedure recommended by the CDC to ensure clean water in dental offices.

It’s well known that dental unit waterlines are a breeding ground for the very pathogens dental practices are trying to avoid, such as Legionella. Therefore, dental staff must use a combination of chemicals, procedures and protocols to keep patients safe.

Luckily, there’s an alternative that’s more effective at removing bacteria and viruses from waterlines, simpler to implement, and safer for staff, patients and the environment. It has been utilized in medicine and dentistry in the European Union for years but is only now being introduced in the U.S. It’s called ozone, and it’s part of Toppen Dental’s three-pronged approach to water disinfection in the dental practice.

Toppen Dental founders Owen Boyd and Al Dube sat down to discuss ozone and quantum disinfection, two technologies they offer to keep dental practice equipment and waterlines sterile and safe.

The Oz

Ozone gas is often used in water treatment as a chemical-free method of disinfection. The process, called ozonation, has been used in bottled water treatment since the 1970s. Before that, the shelf life of bottled water was about 90 days, Boyd says. While the dental community continues to rely on chlorine tablets and other chemical treatments for dental unit waterlines, ozone is more effective at combating microorganisms in water.

Toppen Dental uses ozone in one of its marquee products, The Oz. The Oz is a spray bottle that uses an ozone generator to sanitize the water. It’s designed to replace glass cleaners, hard surface cleaners, surface disinfectants, deodorizers and other products.

The process is simple: Fill the bottle with tap water. Once ozonated, water from The Oz can kill pathogens such as E. coli, Salmonella, and MRSA.

There are two big benefits to The Oz, according to Boyd and Dube. The first is that it kills bacteria within 30 seconds. The second is that it’s safe to use on any surface, including dental chairs. In fact, in a video posted on Toppen Dental’s website, Boyd sprays water from The Oz directly into his mouth, highlighting just how innocuous ozone is to our health.

“I always tell people, if you’re using a cleaner, open up a cabinet under your kitchen sink and read the warning labels,” Boyd says. “You probably would not use most of the cleaners you have underneath there.”

Unlike most cleaners, which contain around 40 to 60 percent isopropyl alcohol, ozone can be used on any surface and provides a deeper clean.

“Because it’s a gas in water, sort of like CO2 in your beer, that small ozone molecule gets into the little crevices that you have on glass and wood and fiber,” Boyd says. “So, it’s going to sanitize deep down where most of your other large-molecule cleaners strip stuff off the surface and leave bacteria in the crevices. You may have done a great job cleaning your surface, but bacteria are still there, resident.”

“You can use this spray bottle and spray it on the chair itself and you’ll sanitize it, and the only byproduct is water and oxygen,” Dube adds.

The Oz is part of a family of ozone products from Toppen Dental, including a faucet and a wall mount for chairside water bottles.

Continue to page two to read more...

QDfx

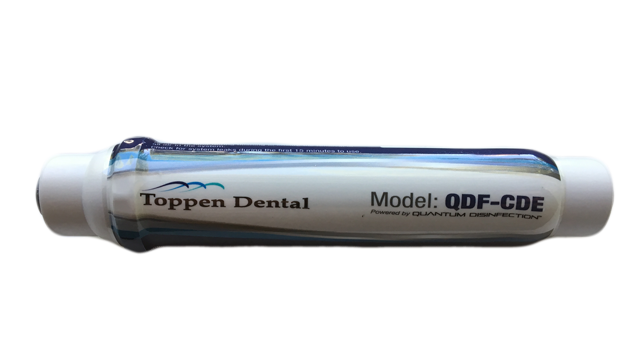

The other technology Toppen Dental offers is QDfx, an inline filter that utilizes quantum disinfection technology to destroy bacteria and viruses in the water. Within the filter are tiny ceramic balls that attract electrons from microorganisms, stripping away their outer membrane and destroying the entire cell.

“It essentially uses a charged ceramic chemistry, whereby the cation charge is so powerful that it attracts bacteria and steals the bacteria’s outer ring of electrons, killing it in a tenth of a second before destroying its innards,” Boyd says.

This process is called lysis, and it affects free-floating bacteria as well as bacteria in biofilm. Compare this to a chemical treatment, which requires 30 to 90 minutes of contact to combat the DNA of free-floating microorganisms. Chemicals also have little effect on the biofilm, where most microbial activity takes place.

Boyd and Dube say that the QDfx technology provides a 24/7 secondary kill.

“Just by doing dental procedures on their patients, dentists are going to have disinfection accomplished,” Boyd says. “They don’t need the protocols.”

They add that using QDfx is a much simpler process. It takes about five minutes to install the QDfx cartridge, which plugs into the dental unit waterline with a quick connect fitting. There’s no daily process to attend to, as the cartridge is designed to be replaced annually.

Benefits

These technologies work together to offer significant benefits to dental team members, patients and the environment as a whole. While most water treatment options are considered pesticides by the EPA, The Oz and QDfx are devices that add nothing to the water. Therefore, staff members aren’t vulnerable to chemical byproducts and patients aren’t ingesting pesticides. The Oz can even be used to sanitize hands before a procedure without dealing with the sticky residue that alcohol leaves behind.

“We think that there’s a bit of a missing link in some of the things that are going on in dentistry,” Dube says. “One of the pieces is how you have chemistries that may solve one particular kind of problem, but then they create a secondary problem. If you have a disinfectant that creates an aerosol that’s a potential carcinogenic, you could be creating a hazardous potential for a staff member.”

Boyd and Dube emphasize that a priority of Toppen Dental is to create products that solve existing problems without creating new ones.

“In our company, everything has to have an oral health benefit, a human health benefit and an environmental health benefit,” Boyd says. “It can’t meet one of the three. It’s got to meet three of the three, or we’re not going to develop that as a product. It’s that simple.”