Take Control of Your Production Dollars With Roland DGA’s New DGSHAPE Dry Milling Solution

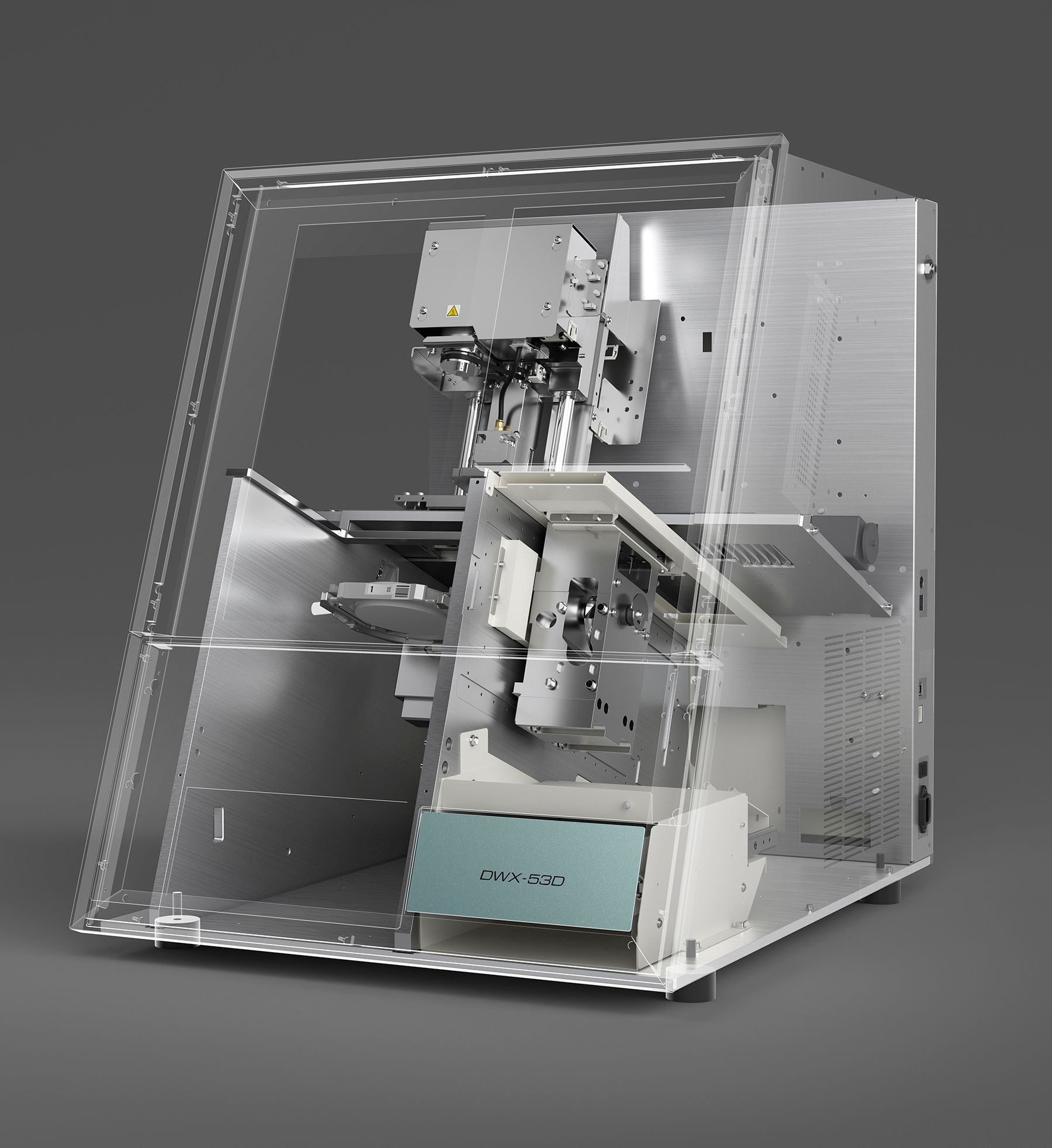

The company has launched an upgrade to its flagship single-puck dry mill, the new DWX-53D milling solution.

Just Launched: The DWX-53D is suitable for a variety of cases, including prosthodontics and more.

Laboratories and dental professionals alike are very familiar with the Roland DGA name and reputation. For over a decade, the company has expertly manufactured DGSHAPE DWX open-architecture CAD/CAM milling solutions for dental laboratories and has recently expanded their offering to specialty and general dentistry offices. As of October 1, 2024, DGSHAPE launched an upgrade to their flagship single-puck dry mill, the new DWX-53D milling solution. The upgrades to their best-selling flagship product makes the DWX-53D the ideal dry milling solution for general dentists, prosthodontists, oral surgeons, dental service organizations (DSOs), and in-house labs. Roland DGA dental marketing manager Lisa Aguirre explained how the enhanced dry milling solution can increase production dollars per hour while creating a better chairside patient experience.

Lou Shuman (LS): What is the difference between the DWX-42W Plus and the DWX-53D milling solutions?

Lisa Aguirre (LA): The DWX-42W Plus is anything but the traditional chairside milling solution as its true open-architecture ecosystem platform allows users the freedom in choice of intraoral scanner, CAD software, and restorative materials. Clinicians can produce same-day restorations from commonly used materials like traditional precrystallized lithium disilicate and pre-sintered chairside zirconia. The DWX-42W Plus is commonly utilized in clinical dental offices for everyday bread-and-butter restorative procedures such as posterior single crowns.

Whereas the new DWX-53D milling solution is the ideal single-puck dry mill for the in-office production of advanced applications such as All-On-X cases, traditional and implant supported dentures, and other removable and fixed prosthetics. We consider these to be advanced applications as these services are traditionally being provided by prosthodontists, oral surgeons, and general dentists who are performing full-mouth reconstruction cases.

LS: What kind of software is needed with DGSHAPE DWX milling solutions?

LA: DGSHAPE prides themselves with their truly open-architecture ecosystem platform. That means it doesn’t tie users to any specific software, subscription/maintenance fees, or proprietary control source. Clinicians are free to choose their preferred CAD/CAM software, scanners, and restorative materials.

LS: Can I replace my dental laboratory with the DWX-53D?

LA: Roland DGA continues to emphasize the importance of maintaining the clinician’s relationship and collaboration with their trusted dental laboratory partner. Same-day dentistry can be productive and beneficial, but when the restorative application becomes more complicated—for example, a subgingival restoration or even a highly esthetic anterior case—the clinician should consider collaborating with their trusted laboratory in order to achieve an optimal clinical outcome.

In-office milling can easily add value to a practice by being able to produce certain applications in-office, when appropriate, and creating a better overall experience for the patient.

LS: What excites you about the new improvements to the DWX-53D?

LA: Essentially, the best just got better. We like to say that the innovation was “built from the outside in” with the DWX-53D. First, the spindle has been upgraded, now with 1.5 times more gripping power than the previous DWX-52D Plus model. This allows for even more precise milling of materials like PMMA [polymethyl methacrylate] and other very rigid plastics along with faster milling times.

The frame structure has also been redesigned and reinforced, creating more stability when milling and helping to minimize routine maintenance procedures. The included open-edge adapter accessory allows for advanced 90-degree-plus milling capabilities to reproduce 100% of the case design. This is perfect for milling of large full-arch and/or highly esthetic cases.

One exciting and useful aspect of the innovation is the addition of a built-in web camera so the practitioner can monitor inside the actual milling chamber of the machine.

LS: Can my dental office really benefit from having a DWX-53D in-office?

LA: The return on investment for bringing milling in-office can quickly become apparent. In-house milling can make everyday and complex restorative cases more profitable by increasing production dollars per hour and in-office efficiency. For the patient, this translates to a better overall chairside experience, reduced time between visits, and fewer visits overall. For those who are ready to take control and do more advanced applications in-office, you can upgrade your practice with the DWX-53D for just under $30,000.

LS: How can practitioners learn more about the updated dry mill and contact you?

LA: For any questions, clinicians can email dental@rolanddga.com. For availability and purchase, contact www.rolanddga.com/dealers, or for more specific information on the mill, visit www.rolanddga.com/DWX-53D.