Stratasys Introduces Multi-Material Dental 3D Printer

This new 3D printer from Stratasys boost efficiency through its multi-material capabilities as well as its minimization of post processing.

Stratasys Introduces Multi-Material Dental 3D Printer

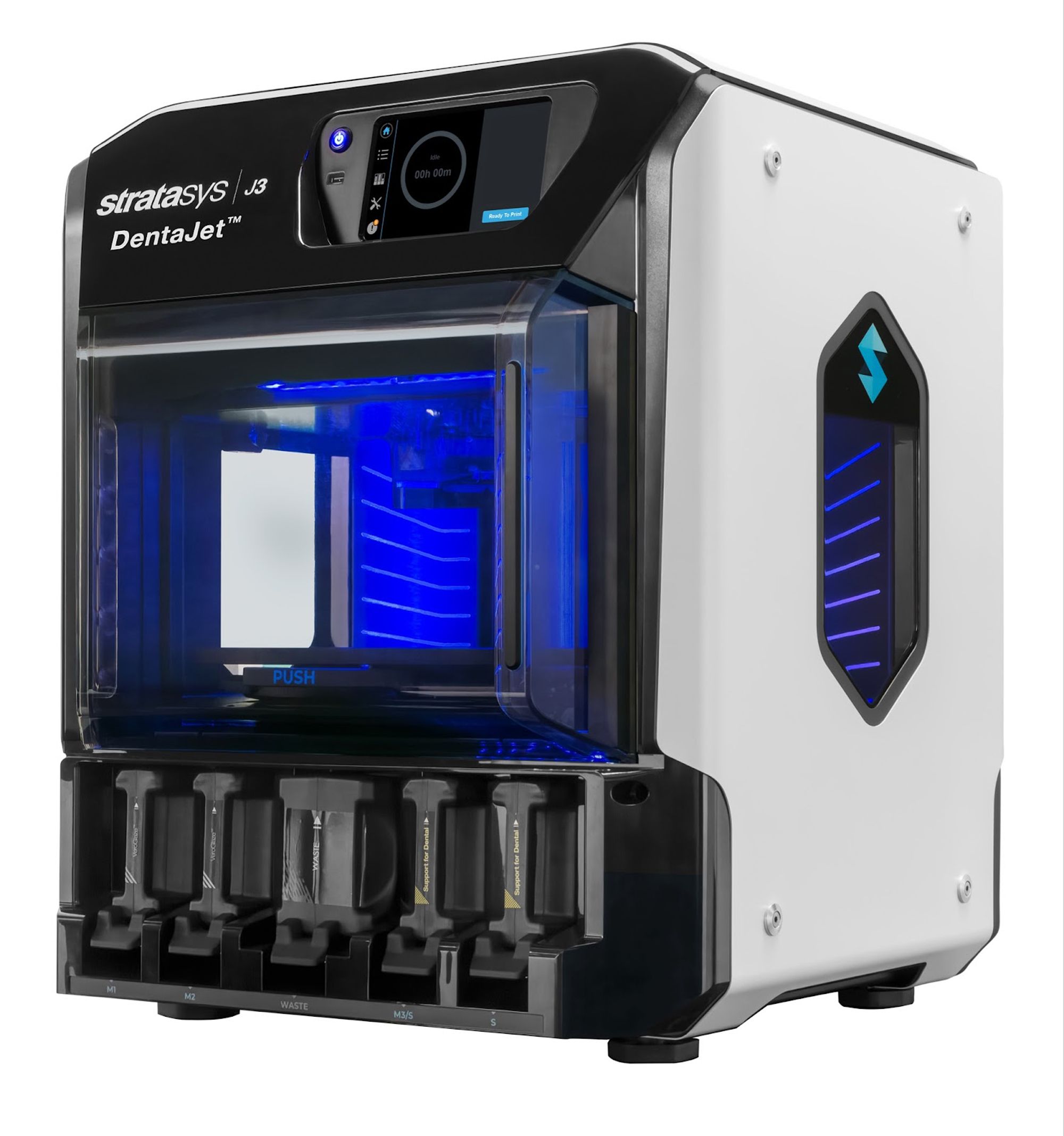

3D printing company Stratasys has announced the launch of its newest printer, the multi-material J3™ DentaJet® 3D printer. Designed to be suitable at an entry-level, the J3 DentaJet features biocompatible resins that can be used to create mixed parts for crown and bridge models, implantology, and orthodontic models in the same print job, according to a press release from Stratasys. It has a large circular build tray and a High-Speed mode to help labs increase their efficiency, according to Vice President of Dental at Stratasys Ronen Lebi.

“This printer is a great value for smaller dental labs that have previously been limited to small, single-material, table-top 3D printers and are ready to level up their dental production to offer higher-quality digital dental products,” Lebi says in the press release. “Adding a J3 DentaJet 3D printer can help labs produce best-in-class dental applications that require extreme accuracy at scale as demand is growing.”

Part of the J3 DentaJet is Stratasys’s proprietary PolyJet™, jetting technology. This is said to cure printed parts during the printing process, further boosting efficiency by minimizing post processing. An added benefit to this is that lab employees do not need to handle uncured resin, a boon for any lab personnel.

The J3 DentaJet 3D printer will be available for viewing at the LMT Lab Day Chicago, from February 23rd through the 25th as well as the IDS global trade fair in Cologne, Germany from March 14 through the 18th. It is expected to ship in March, 2023.

ACTIVA BioACTIVE Bulk Flow Marks Pulpdent’s First Major Product Release in 4 Years

December 12th 2024Next-generation bulk-fill dental restorative raises the standard of care for bulk-fill procedures by providing natural remineralization support, while also overcoming current bulk-fill limitations.