Sterngold Celebrates 125 Years of Innovation

Manufacturer of dental restorative solutions continues to evolve, lead the way in dental implant, attachment developments, and more solutions, with patient care a driving force.

A Milestone Wall that Sterngold unveiled at a short but sweet commemorative event on Tuesday, Sept. 13, 2022.

Not many companies in any industry can say they’ve been in business for 125 years, and even fewer can claim to have come out on the other end of a pandemic thriving in new and very impressive ways.

But this month Sterngold Dental is celebrating 125 years of serving the dental industry and the company’s superb track record is a great example of the importance of adapting to a changing environment. Along the way during these many years, Sterngold Dental has responded to changes in the industry while also showcasing the need to have a sound foundation and clear vision to stick with to ensure sustainable, long-term success.

Company president Gordon Craig says never losing site of what’s most important has been a staple in the company’s success. He says this means first and foremost, helping to deliver affordable products and services designed to improve the lives of dental patients. Secondly, making sure to assist and take care of Sterngold’s customers, who in turn lead the way to delivering this optimal patient care.

Sterngold Dental is a US manufacturer and distributor of a wide array of products in restorative dentistry with a storied history that traces back to 1897. The company carries the largest selection of attachments, the popular MOR® mini implant, and the TRU® and PUR® conical and internal hex connection implant All-in1 bundle. Other recognizable brands include the ERA® implant system, SternSNAP®/SNAP Angled® attachments, and RC housings. On the consumables side, clinicians and lab technicians alike rely on the EZ PickUp®

, InstaTemp® Max, QuickLine ®, and SternVantage® consumables line. Additionally, they provide digital dentures featuring the Baltic Denture System® of Merz Germany to support those involved in the growing digital dental market.

“We want to have everybody able to have a level of quality, affordability and access,” explains Craig, who started his career in corporate marketing. “The company has been around for quite some time. We have that expertise, we have that knowledge, and we have the path to be able to help you and to point you in the direction to make sure you have everything covered.”

A Sterngold employee at work in 1947.

While people are most likely to recognize the name Sterngold Dental—or the shorter reference—Sterngold, today’s Sterngold Dental, LLC is the union of 2 companies with impressive dental histories: APM-Sterngold and ImplaMed.

Call the company by whatever name you prefer, just know that a company that has been around for 125 years has quite a story to tell.

“I think you’ll see some themes along the way on how companies need to adapt, to stay relevant and continue to bring value to the customers,” Craig says while reflecting on Sterngold’s past. “That’s really what we try and do here at Sterngold.

“If you look at what the company was 125 years ago, it’s completely different. Certain companies can still do some things like they’ve done 125 years ago, but certain industries, like dental technology…certainly in the last 20 years have significantly advanced with the digital developments and workflows injected into the industry.Prior to that, the world of dentistry was a very steady and predicable industry.

Technology and digital workflows have changed everything in dentistry and Sterngold changed along the way. But even today, the company continues to support labs and clinicians using both analog and digital technologies.

Getting Started

Adaptation and advancements have been brought in to really shape the future of the industry. Sterngold has the expertise and the knowledge and has “…that pathway of what works and what doesn’t work”, says Craig, who grew up in New Jersey. They’re the problem solvers.

“We do still have some of the legacy products that we’ve maintained because we’re kind of like the L.L. Bean of the dental space. You know that if you’re in trouble and you don’t know where to turn, you can come to us. We’ll either be able to help you, or we’ll be able to point you in the direction where you can get the help. We are a hub to this industry in that regard.”

In the early days, Sterngold was very heavy on the lab side. It wasn’t until the company started to get into implants that it branched over to the clinical side. Now, Sterngold has a full circle workflow for both labs and clinicians.

Company president Gordon Craig

With Craig serving as a tour guide, here’s a look at some of Sterngold’s storied past.

From 1897 all the way up until around 1940, Sterngold focused primarily on precious metal alloys, alloys used for precious metals in dentistry including casting.

The company originated in Manhattan and later moved to upstate New York, before heading to Stanford, Connecticut in the 1960s. In 1978, Cookson—which hired Craig right out of college in 1994—acquired Sterngold and moved the company to Attleboro, Massachusetts in 1984. The company has resided there ever since.

Originally Sterngold was located in an industrial park with 6 or 7 sister companies, all part of Cookson at the time. The spot was known as the jewelry mecca of country with companies like Josten’s, located there.

The company’s first big shift away from just alloys came when it started to take alloys and create precious metal attachments. Instead of just selling ingots, Sterngold was now starting to create precious metal attachments. In the 1960s, there was more of an emphasis on different types of attachments as that segment of the market continued to grow.

Sterngold has always focused on the patient removable restorative solutions side rather than on the fixed side of restorations. They never got into porcelain or ceramics or other materials for crowns. It produced attachments on natural teeth and then attachments for implants.

In the early 70s into 80s dental implants really started to come into favor, and Sterngold was primed to play a key role.

“I would say the biggest turning point for Sterngold was in the early 80s, when we created the ERA [implants],” Craig says. “That was the first time that we said that instead of having metal to metal, you know male female, metal-metal attachments, we’re going to have metal to a performance nylon. So, you have one side, with the nylon that wears. That’s where the maintenance comes in.”

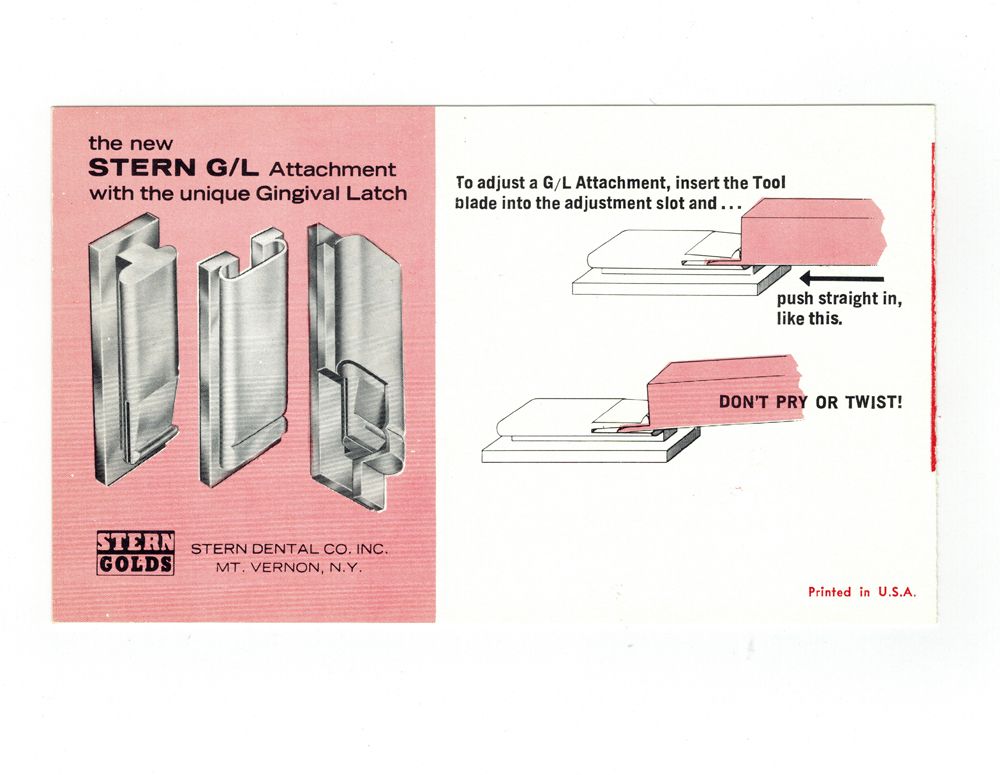

This publication from 1960 features the STERN G/L Attachment with the unique gingival latch.

This development provided much better longevity and at the same time the ability to adjust the level of force. With ERA attachments, you can basically customize the level of force that is used to take the attachment together and bring them back apart. Now you can customize a level of retention based on what’s best for the patient.

Sterngold continued to develop the ERA line for the next decade or so, coming out with attachment families within that brand. Next came implants, abutments, single-unit crowns and now partials.

“That really kind of leap frogged us to the head of the attachment scene at that time,” Craig says.

But then another big move was about to give the company yet another boost as Sterngold continued to evolve.

With dental implants starting to come on, and Cookson still owning Sterngold at the time, the global company with massive resources funded the move for Sterngold to acquire an implant company, ImplaMed, in the early 90s. The Florida company was making external hex implants and the move gave Sterngold the ability to not only handle the attachment level, but now the implant level.

Mini Implants and Consumables

As Sterngold added mini implants and got more involved in consumables, the company became more of a one-stop shop for both lab technicians and clinicians.

Up until 1985 the company’s focus was purely on laboratories. Then from 1985 on to currently it’s focus is labs and clinicians. This is based on having products catered to clinics and to labs, and then products in the center that cater to both.

“We decided in the early 2000s to develop a mini implant,” Craig explains. “We said, ‘look we can take an ERA and put it on a small diameter implant and make it a one-piece design’. It started to act as a transitional interproximal to conventional implants during the healing phase…so it gives the ability for the patient to have some sort of restorative solution that is immediate and gives them some function.”

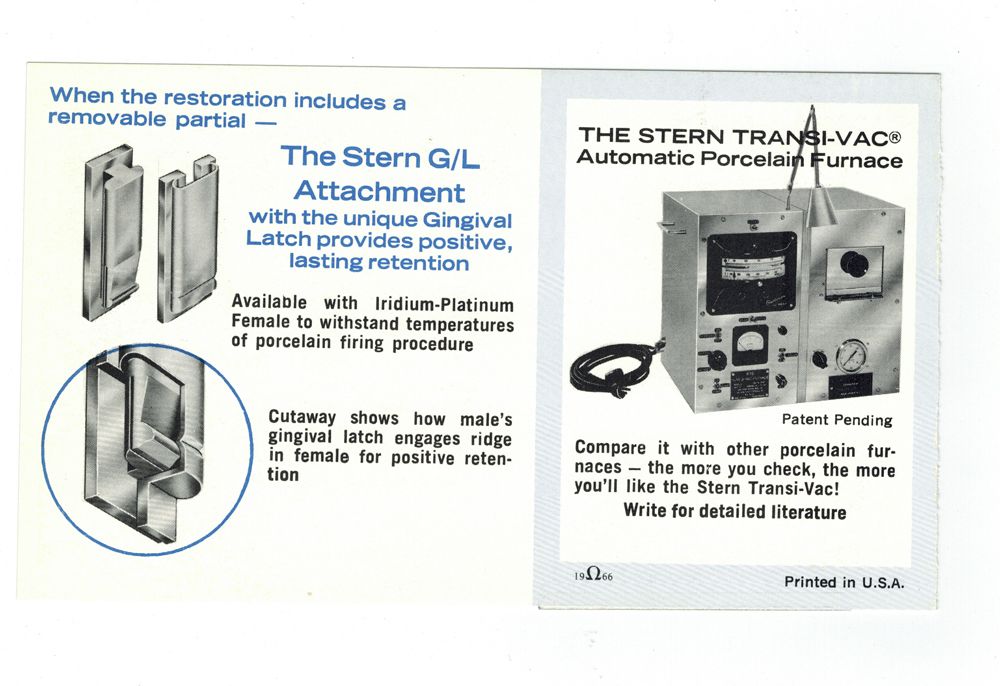

Company products from around 1970.

At the same time it helps to protect the conventional implants that are healing under the tissue. That’s how the original ERA mini implant was developed.

The company applied for long term use and received approval by the FDA to not only have it as a transitional but to have it for long term. They continued to collect evidence using the cases they were doing…and Craig says, “Lo and behold, [we learned] if done the proper way the mini implant would integrate just as well as a conventional implant.”

He adds that you wouldn’t use a mini implant on a molar by itself… but if you’re using a mini in an overdenture situation where it’s partly tissue supported, you can actually create environments where that implant will last a lifetime for the patient and be less invasive.

“Maybe the patient has been wearing dentures for a long time so much that they don't have enough bone to put in a conventional [implant] without grafting, all this higher cost treatment,” Craig says. “So, the theme around everything is about access to restorative dental materials. We want every patient of any socioeconomic class be able to have a level standard of care. Quality is No. 1 for us, but in addition to quality is affordability and access to these materials is also very important.”

Sterngold makes all of their own implants and all of the abutments. Because of this, the company controls about 70 percent of its supply chain and can deliver on quality, according to Craig. “And we can do things efficiently to create that affordability so that the access is there for any type of person,” he adds.

On the consumables side of things, the company did a joint venture with a company in Germany to supply consumables, and it’s called Sterngold Restorative Systems. It consists of the products that are consumed or needed to facilitate an implant or attachment case.

This came before the digital evolution, so it includes materials you need to take the impression, the cements, custom tray material, attachment processing tools material, and laboratory components like duplicating material and putties.

“We created Sterngold Restorative Systems and all those consumables to go along with that. It really started to shape up to be one-stop shopping for not only the restorative dentist but we’re also doing a similar pathway for labs. Really catering to both,” he says.

For the past 15 years Sterngold has been focusing on product development and advancements to bring more products with the implant, attachment and restorative line into the digital world. The company has added scan bodies, custom abutments, Digital Dentures, intraoral scanners and a variety of digital solutions designed to assist digital workflows.

With a vast number of dental professionals now investing in state-of-the-art equipment, versatile software and 3-D imaging services to better themselves and their patients, Sterngold offers an array of products and services aimed to help those looking to improve their digital efforts.

“We’re serving the digital track, but we also maintain the analog offerings,” Craig says. “We live in both worlds.”

Surviving a Pandemic

As the company continued its expansion, it developed the Vision 2025 plan which was a 5-year plan instituted right before COVID hit in early 2020. It was an aggressive plan to grow the company with a huge internal communication plan. Then came the pandemic, which brought the dental industry to a screeching halt.

These were scary times for dentists, manufacturers, and the entire industry.

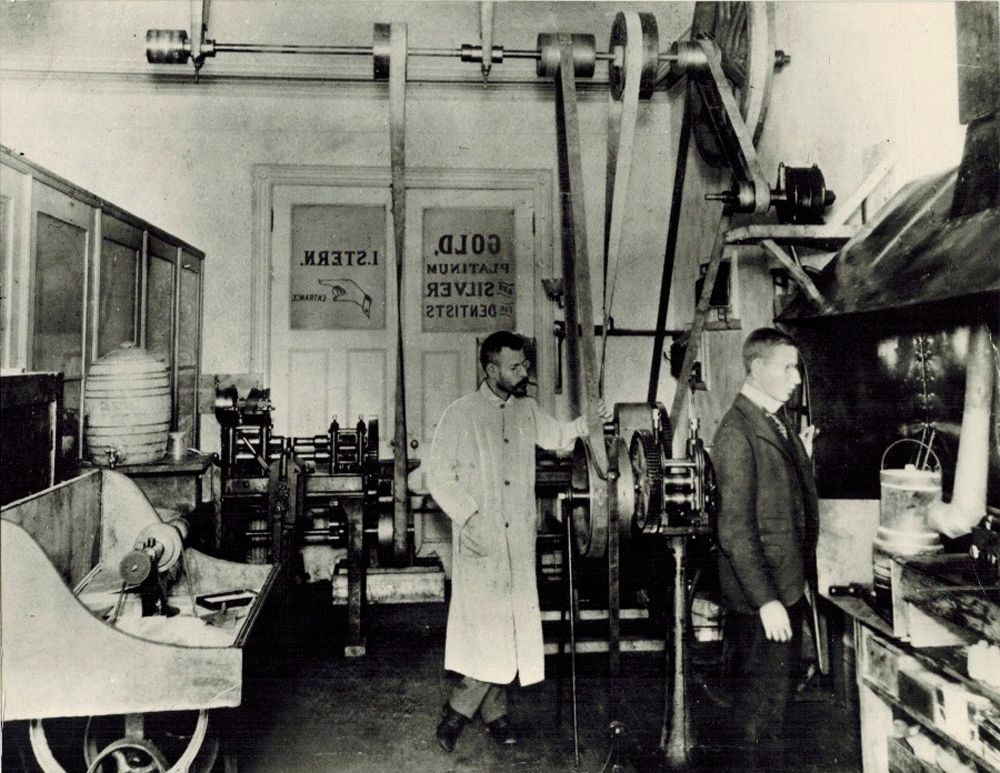

Sterngold Dental has been in business for 125 years now. Here's a photo from the company's original facility.

“I was on the phone with everybody I knew in the dental industry and we were all in this together. On day one of the pandemic nobody knew anything. All we knew is that we’re getting calls by the state and the ADA is telling people, ‘Don’t go to the dentist’,” Craig recalls. “None of us in the current times has ever endured any kind of pandemic to that level, but just sitting here in the industry that we’re serving, it was like we were in a boat and someone stole the motor and we didn’t have any oars, and said, ‘Alright have fun’. It was kind of chaotic.”

To make matters worse, the governor of Massachusetts announced in March 2020 that everyone with an office building or a manufacturing facility could not have more than 10 percent of their staff in the building at one time.

“I had to make a decision, right. I could have fought to be a critical supplier, since we are a medical device,” he says. “But I met with my executive team and we said, we can fight. I’m ready to fight. But what are we fighting for because our industry is closed?”

The company stayed at it, even as much of the dental industry went from its normal operating level to as low as 12 percent of normal business. This drought lasted 2 months as dental practices were shut down for all except for emergency treatment in most states.

“We operated very lean during those times, and we got to learn Zoom very, very quickly,” Craig explains. “I was taking a lot of walks at lunchtime with my wife.”

He admits to having concerns about the future and if Sterngold would ever fully rebound from those crazy pandemic times.

Craig confided in a number of people in his network, talking to lab owners, colleagues in the industry and even competitors.

During COVID Sterngold developed a #ReadyNow campaign. The company went on the aggressive once things started to go up and things started to come back into light, they had this campaign ready—stating “We’re Ready Now!”

During the pandemic the company continued to ship products through its website, often dropping off shipments at a Kinkos to be delivered when FedEx and UPS stopped making pickups.

“We never closed the office. We had our people at home, our Voice over IP phones, headsets on, computers, customer service, tech support—all that was still open,” he says. “We’d come in on the weekend. Whatever it takes. It was a strange time. No one was on the road…but we got through it.”

With the campaign in place and heavy engagement with its customers that included a lot of webinars, Sterngold weathered the storm.

“We were doing a lot of showing and educating and just helping people get back,” Craig says. “By June of 2020, it was kind of like a normal June. The faucet was turned back on.”

Then came July and August, which were banner months. The company was not only back on track, but thriving.

“It was the best July and August we ever had in company history, because that was the back pressure,” Craig says. “Halfway through September we started seeing that sort of normalizing again.”

When December came around, the company looked back and saw that Q2 was a disaster—just like it was for pretty much everyone at the onset of COVID—Q3 was phenomenal, and then Q4 was pretty normal, with business slightly up.

“So at the end of the day, we finished the year slightly up, which was a whole lot better than we thought based on going into COVID,” he says.

Moving Forward

Never losing site of the end result that is delivering optimal care to dental patients, Craig says the company will continue some processes it learned during the pandemic, as well ones developed over the past 125 years.

“We want to help our customers be more efficient. Through our labs, to the doctors, and then ultimately the patient. We're focusing on communication between all parties. We want enhanced, super-efficient workflows,” he summarizes.

In order for a company to be successful for more than a century, it has to deliver and it has to have many loyal customers. Sterngold checks both of these boxes.

One clinician, who has been in practice for almost 5 decades, credits companies like Sterngold with helping him best help his patients.

Joseph Buttacavoli, DMD, of Buttacavoli Dental Arts in New Jersey, has been a dentist for 47 years, and has been doing implants since 1978.

He liked the ERA attachments the first time he got his hands on them and then the same can be said about Sterngold’s mini implants.

“Their ERA attachments always worked very well, and I got very involved with doing their mini implants and wound up lecturing for them for a while,” Dr Buttacavoli says. “I've had a very close relationship with them and I've enjoyed working with them. They've been great people. The president of the company, Gordon, is a very nice guy and they've been very helpful. Whenever I have technical questions and everything the technical department is very helpful. They want to make sure that people are comfortable with what they’re doing and they've got very good products.”

Having lectured in the past and worked with dental staffs getting started with implants, Dr Buttacavoli has helped produce a new generation of younger clinicians eager to work with implants and to take advantage of the products and education resources available from a company like Sterngold.

“It’s a joy to work with the people who answer the phone when I place an order,” the longtime dentists says. “And I could not lecture for a company that I didn't believe in what they would tell me. To me, the mini implants are some of the best implants we've got.”

With Sterngold’s assistance, Dr Buttacavoli is just one of many clinicians who have been able to help to improve the quality of life of plenty of patients indeed of restorative care. The company has no plans to stop innovating just because it has reached 125 years of success.