Step by step: An easier cost effective way to deliver articulated cases

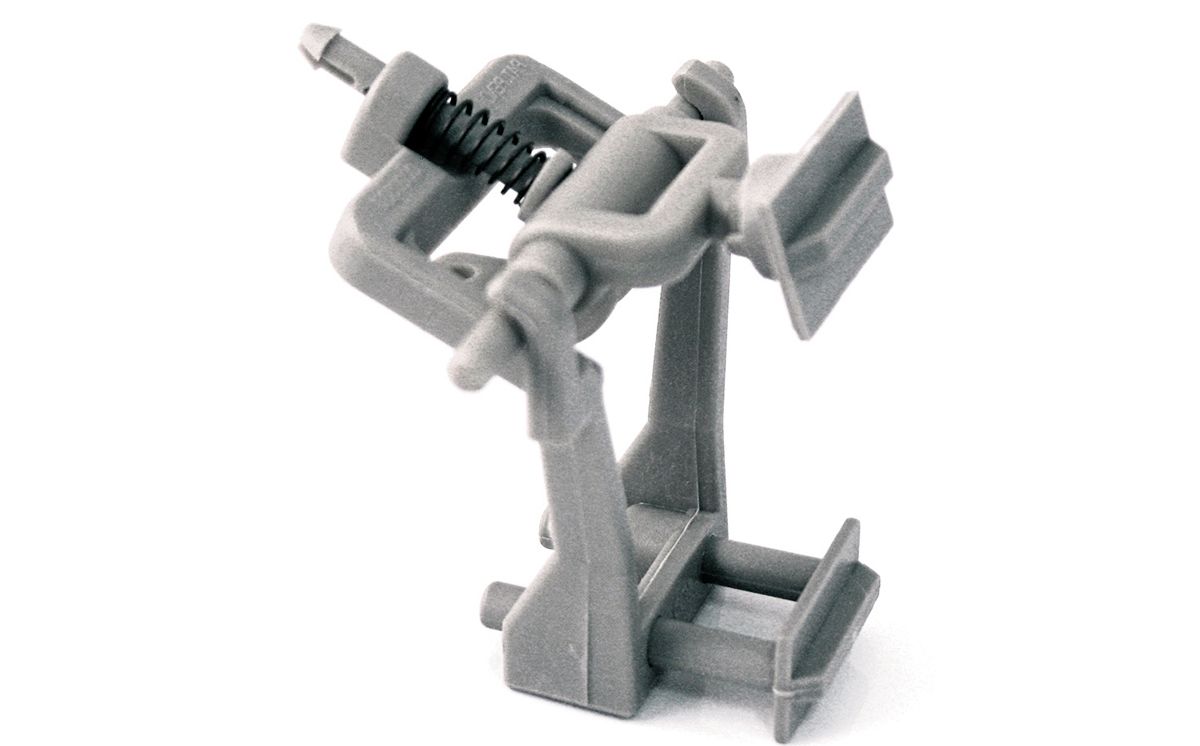

Many other plastic articulators have a tendency to rock back and forth or they can flex and bow, which makes it difficult to work. The dental technician constantly has to reposition the articulator to make it stable. Wondertech Articulators are made of a more durable, stable plastic, which helps to make a better end product.

Exploring how the Wondertech Small Articulator can help you provide better cases to your clients.

Durable and stronger than most other plastic articulators, Wondertech Articulators (from Dental Creations) do not have stability problems. The articulators function much like metal “Foster” articulators.

Once articulated, the case can easily be put through the same functions and excursive movements as metal or semi-adjustable articulators.

Tom Zaleske on making procecessed baseplates more efficiently

Many other plastic articulators have a tendency to rock back and forth or they can flex and bow, which makes it difficult to work. The dental technician constantly has to reposition the articulator to make it stable. Wondertech Articulators are made of a more durable, stable plastic, which helps to make a better end product.

The Wondertech Articulator functions the same as all other popular small, fixed metal articulators and is disposable, which eliminates the messy clean-up that is required with the metal articulators. Of remarkable importance, the Wondertech Articulators are affordable enough that the technician can send the finished product to the dental office with the articulator attached. They are also lighter weight than a metal articulator, which saves in delivery costs. By sending an articulator with the finished product, if there is a problem, the dentist can see where the mistake occurred. Metal articulators are too expensive, so they cannot be sent to the dentist with the finished product attached.

Additionally, Wondertech Articulators are designed to be easier to work with because whether a lab technician is doing crown and bridge work or a full denture, the Wondertech Articulators can be easily used for both applications. When working with metal articulators, the technician either has to use the metal crown and bridge articulator or use the full denture articulator to make the application.

Finally, Wondertech Articulators are easier to mount. The bottom piece slides in and out and the top piece will move up and down or from left to right which makes it easier to adjust the model to the right angle. With these articulators, the technician can send the finished product to the dentist with the articulator attached. After simply trimming the excess plaster from the outside of the product, articulator and product can be sent to the dentist. With metal articulators-and some plastic options-before sending the finished work to the dentist, it must be removed from the articulator, the excess plaster knocked off and the model trimmed while ensuring the model is not broken or cracked. The Wondertech Articulators save bench time and, therefore, money for the dental lab.

Related: 6 easy ways to increase productivity in your lab

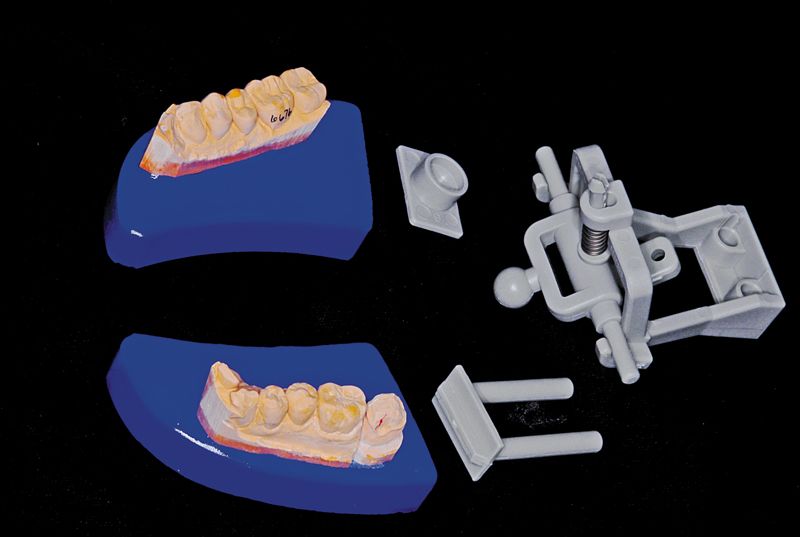

Below is a step-by-step technique for using Wondertech Articulators, a great option for any dental technician looking to find an affordable and efficient alternative to traditional, metal articulators.

Next page: Go step-by-step ...

Using the articulator

01 Using a cyanoacrylate gap filling medium glue, apply the adhesive to the model base. This will hold the model in place for proper viewing of the final case. (Fig. 2; all figures in video below)

02 To prevent a misaligned articulation, center the upper ball receiver attachment to the middle of the model base. This will ensure a successful result when it’s time to send the case to the client. (Fig. 3)

03 “Snapping” in the ball joint into the ball receiver attachment assures you have properly connected the two. Your upper model is correctly assembled because the models will be level with the bench. (Figs 4 & 5)

04 Assemble the lower arm assembly by aligning and sliding the two arms with the two holes in the articulator base. (Fig. 6)

05 Trim bite or triple tray and place onto the models. This step makes certain the final model will match the bite. (Fig. 7)

06 Set the bite by bringing the two models together with the bite in place. (Fig. 8)

07 Now place the lower assembly into place in its place below the prepared upper portion. Via the flexible ball joint, the articulator will move around to aid in articulation. (Fig. 9)

08 Using a cyanoacrylate gap filling medium glue, adhere the lower assembly onto the lower model. (Fig. 10)

09 Once you know the bite is set, you may glue the upper ball joint assembly into place. (Fig. 11)

10 To finish the articulation, glue the two arms of the lower assembly to the two holes of the articulator base. (Fig. 12)

Using this method, lab technicians can ensure excellent results with Wondertech Articulators. This affordable, disposable solution can help any lab ensure they deliver reliable, esthetic results to their clients every time.

Wondertech Articulators

A disposable and affordable alternative to metal articulators.

Features include:

- Affordable & disposable

- Light weight & easily adjustable

- Made of durable ABS plastic

- Provide stable mounting

For more information, contact Dental Creations at wonderfill.com or call 254-772-4661.

This article originally appeared in the February 2015 issue of Dental Lab Products. For more great, need-to-know lists, click here to subscribe to DLP: http://bit.ly/18S8j4i

ACTIVA BioACTIVE Bulk Flow Marks Pulpdent’s First Major Product Release in 4 Years

December 12th 2024Next-generation bulk-fill dental restorative raises the standard of care for bulk-fill procedures by providing natural remineralization support, while also overcoming current bulk-fill limitations.