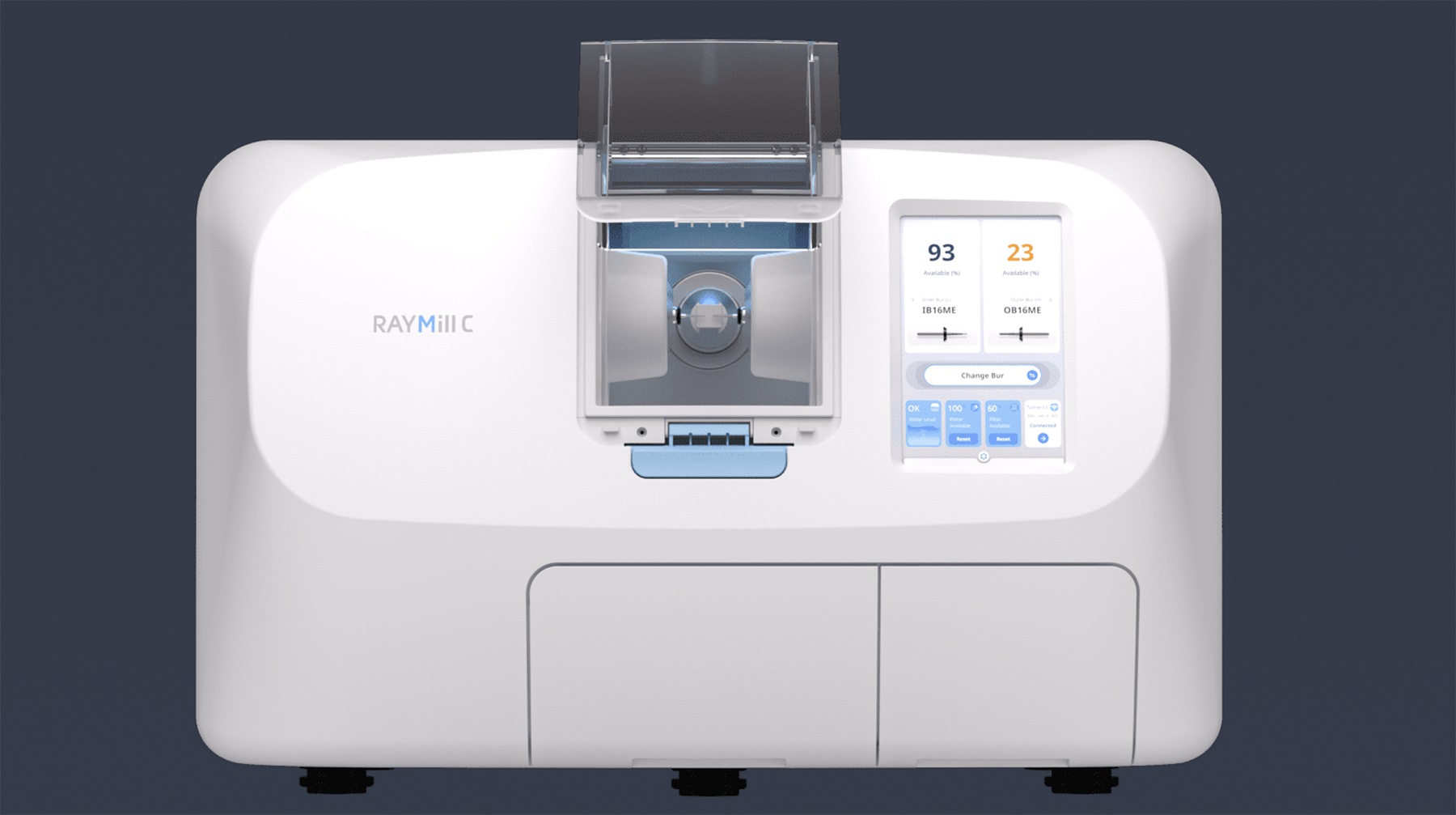

New RAYMILL C Chairside Milling Machine Designed for Speed and Precision

Ray America’s latest launch is described as easy to use and said to deliver great-fitting prosthetics quickly.

New RAYMILL C Chairside Milling Machine Designed for Speed and Precision | Image Credit: © Ray America

Designed for same-day ceramic restorations, the new RAYMILL C chairside milling machine from Ray America features advanced grinding capabilities to address various indications. Boasting the latest in cutting-edge technology and a compact design, the mill is designed for both efficiency and precision. Its advanced dual grinding technology is said to produce top-quality patient fittings quickly. Described as easy to operate by any dental staff member, the RAYMILL C can go anywhere in the practice due to its compact size and quietness (it does not require a separate compressor or direct water supply connection). The device uses a high-frequency spindle 60,000 rpm grinding tech for accurate results within 10 microns during repeated processing. With a diamond-coated cuttable material that provides optimal grinding performance, the milling machine is said to be ideal for thin veneer processing.

It is 25% faster than its predecessor to allow for quicker and more efficient production. Additionally, it can produce glass and hybrid ceramics simultaneously using dual 4-axis machining in less than 18 minutes, Ray America states. The intuitive user interface simplifies workflow for users, who are guided step-by-step through maintenance procedures and tool management. Another benefit of the machine is its Status Check Function, a display with updates on replacement and function for bur, water and filter. The RAYMILL C is designed to deliver a natural-looking prosthetic in 60 minutes or less, from the scan, to design, milling, post-processing and then the seating.

The company’s product offerings include a variety of digital dentistry solutions including scanners, CAD design, CBCT imaging, the RAYDENT Studio 3D printer, and now its latest milling machine.

ACTIVA BioACTIVE Bulk Flow Marks Pulpdent’s First Major Product Release in 4 Years

December 12th 2024Next-generation bulk-fill dental restorative raises the standard of care for bulk-fill procedures by providing natural remineralization support, while also overcoming current bulk-fill limitations.