New Nexa3D Material for Dental Prosthetics Is Powered by BASF Forward AM

xMODEL 2505 rigid beige color material makes it possible for dental labs to optimize their dental model production by taking advantage of a material that delivers robust processing and optimal model accuracy and detail.

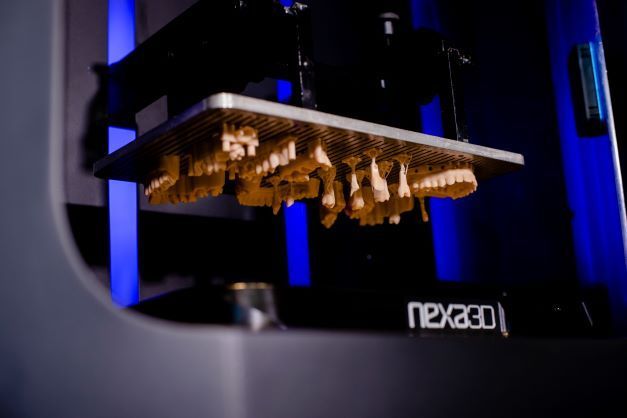

Designed for the ultrafast production of additively manufactured thermoformed dental models, dental removable dies, and other dental model applications, Nexa3D’s new xMODEL 2505 rigid beige color material powered by BASF Forward AM is now commercially available.

xMODEL 2505 printed on Nexa3D’s NXD 200 3D printer is said to deliver higher print accuracy that brings the total cost per model down for dental prosthetics manufacturers by reducing their printing, post-processing, and fitting time. This new dental model material requires no finishing detergents, as the printed models can simply be washed with water.

The collaboration between Nexa3D—the maker of ultrafast polymer 3D printers—and BASF Forward AM leverages their combined capabilities to deliver faster additively manufactured dental solutions for dental labs leveraging the 20X productivity advantage of its ultrafast NXD 200 dental 3D printer. No other manufacturing process offers as many possibilities for faster dental lab model fulfillment, according to the manufacturer.

Combining Nexa3D’s productivity with Forward AM’s tailor-made materials makes it possible for dental labs to optimize their dental model production, taking advantage of a material that delivers robust processing and optimal model accuracy and detail.

“Our extended partnership with Nexa3D enables us to develop a broad range of photopolymers for the most lucrative and fastest-growing segment in digital dentistry,” explains Francois Minec, managing director, BASF 3D Printing Solutions. “Together, we plan to deliver an expanded materials library across Nexa3D’s rapidly growing portfolio of photoplastics (SLA) and thermoplastics (QLS) for the benefit of our customers around the globe.”

“For dental labs and prosthetics manufacturers that are competing for higher share, based on service levels, fast just got faster thanks to BASF’s new generation of dental materials,” says Kevin McAlea, COO of Nexa3D.

Both companies are committed to democratizing access to additively manufactured dental, industrial and consumer products at scale. With NXD 200 dental printers’ 20X productivity gains, and up to 85 percent lower total cost of ownership, dental labs can now access higher productivity, better functionality, and exceptional cost effectiveness, McAlea adds.

BASF 3D Printing Solutions GmbH is headquartered in Heidelberg, Germany, and focuses on establishing and expanding the business under the Forward AM brand with advanced materials, system solutions, components, and services in the field of 3D printing. Nexa3D’s photoplastic printers are powered by its proprietary Lubricant Sublayer Photo-curing (LSPc) and its thermoplastic printers are powered by Quantum Laser Sintering(QLS).

ACTIVA BioACTIVE Bulk Flow Marks Pulpdent’s First Major Product Release in 4 Years

December 12th 2024Next-generation bulk-fill dental restorative raises the standard of care for bulk-fill procedures by providing natural remineralization support, while also overcoming current bulk-fill limitations.