How digital milling can improve outcomes and streamline processes

We spoke to a dentist and a dental technician to find out how the Zenotec select hybrid mill and e.max (both from Ivoclar Vivadent) can work to create better restorative workflows and patient outcomes.

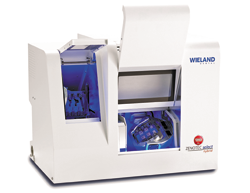

For the past decade, IPS e.max from Ivoclar Vivadent has been one of the most-prescribed materials for restorative dentistry. And for a long time, the ability to mill it was mostly restricted to chairside options. But Ivoclar Vivadent announced the Zenotec select hybrid mill in 2014, a mill specifically designed for the dental laboratory that would mill IPS e.max CAD. Since then, Ivoclar Vivadent has released several updates to the e.max line, providing additional esthetics and strength.

To find out how the addition of the Zenotec select and updated materials has changed the digital workflow, we spoke to Chris Roman, a dental technician who works with a Zenotec select hybrid and with e.max CAD. We also spoke with Trey Wilcox, DDS, a dentist who works closely with Roman’s lab on a variety of restorations, including restorations made with a digital workflow using the Zenotec select and e.max materials. Here’s what they had to say about how the digital workflow really works in the context of a busy lab, and how patients are responding to digital restorations.

Q&A: Sarah Anders, COO of Ivoclar Vivadent North America, explains what "Being Digital" really means

What are your roles on the dental team? Tell us about your laboratory and practice, respectively.

Chris Roman: I am a partner in Oak View Dental Laboratory located in Washington, Pennsylvania and the head technician of the lab along with two other technicians. Our lab has taken a role of working with around 25 doctors, who value the collaborative team approach and enjoy the ability to have a consistent quality product. Currently our lab specializes in crown and bridge and implant restorations with an emphasis on treatment planning to help our clinicians build confidence though education.

Dr. Trey Wilcox: I am a general practitioner with a patient pool estimate of around 1,400 patients. I run a five-operatory practice, with two hygiene chairs and three restorative chairs. During a typical week, I switch between two restorative operatories, and leave the third open for emergency appointments. I usually see between 100-120 patients a month on the operative side of dentistry.

Chris, what’s the workflow been like with IPS e.max?

Roman: We started doing e.max shortly after our lab was founded in 2006. As we all know by now, lithium disilicate has changed our industry dramatically over the last several years. The versatility of this material had given us an arsenal of products that best suit our clients’ needs. We can create everything from single unit anteriors for the most esthetically demanding patients, to our daily “production” singe unit posteriors. Currently, we are also utilizing CAD-ON bridges, bonded bridges and implant retained units.

Related: New bur units expand capabilities of Zenotec select hybrid mill

You also have the Zenotec select hybrid mill. How does that fit into your workflow?

Roman: The mill not only fit seamlessly into the workflow of our laboratory, but almost completely changed our production setup, while making us more efficient and keeping to our standards of a quality product. We have our CAD/CAM system setup with a 3Shape D800 and 3Shape 2015 design software as our server system. We have the ability to work as a client on the server when our case load reaches a certain level. Our designs are then sent to the Wieland software for nesting and CAM simulations before being sent to the Zenotec select hybrid mill.

Dr. Wilcox, what’s the workflow look like when working with a digital lab like Oak View?

Dr. Wilcox: Since I began sending my cases to Oak View, workflow has much improved on my side of the practice. Crown seat appointmentss take less time, with minimal adjustments at most-crowns usually drop into place with invisible margins. I am seriously considering shortening my crown seat appointment times now.

Next page: How the mill was incorporated into an existing workflow ...

Chris, what features made the Zenotec select hybrid the right mill for your needs? What was it like incorporating it into your CAD/CAM workflow?

Roman: Our lab has transitioned to only offering all-ceramic restorations this year, giving us the ability to optimally take advantage of all of the available features of the system. We chose this system for not just its current versatility but also for the future of the next generation of materials and processes.

I originally purchased 3Shape by itself in 2011 and sent all of the designed units to different outsourcing labs depending on what restorations were being produced. When we decided to purchase the Zenotec select, one of our concerns was, how will this system integrate into our workflow? It turns out that after we had the system setup and running (it takes some time to tweak your fits to meet your standards) we realized that we needed to change our workflow to keep up with what this piece of equipment can do daily.

How does the combination of e.max and the Zenotec select hybrid mill work for your lab?

Roman: IPS e.max has become our first choice for restorative units due to the versatility of esthetic options. Add to that the excellent margin adaptation and the fact that it can be bonded, it has been a workhorse for us. Since our work load is approximately 60 percent e.max, it was a no-brainer for us to utilize the Zenotec select. The combination of this mill and the material developed from the same company gives us the peace of mind we need to make sure that we can confidently produce a consistent quality restoration every day.

How is the fit for e.max restorations made with the Zenotec select?

Roman: We have found that our best fit for e.max has been all anterior restorations up to three-unit bridges, full contour posteriors and in the esthetically demanding cases, micro layering of the buccal of posteriors for strength and beauty.

Dr. Wilcox: The results of the digital workflow have been outstanding. I have used multiple labs in my seven years of private practice, and the crowns I receive from Oak View are the best fitting crowns I have come across. Patients leave impressed, usually with the response of “it was that easy?!” Patients are happy when they can be in and out in under 30 minutes with a high-quality crown.

Related reading: Ivoclar Vivadent's new shades for e.max CAD

Anything else either of you would like to add?

Roman: While we have only talked about the machine and the materials used with it, I also think a major influence for us was the quality of support we received from Ivoclar Vivadent. They have been there for us for the simple “duh” questions and have really exceeded expectations with the most complex problems!

Dr. Wilcox: I am thoroughly impressed with the quality and fit of the work from Oak View Dental Lab. Results are consistent, of the highest quality, and Chris and his staff are a treat to deal with!

Top photo: Courtesy of Chris Roman, Oak View Dental Laboratory

Product Bites – January 19, 2024

January 19th 2024Product Bites makes sure you don't miss the next innovation for your practice. This week's Product Bites podcast features new launches from Adravision, Formlabs, Owandy Radiology, Henry Schein Orthodontics, Dental Creations, and Dental Blue Box. [5 Minutes]

Product Bites – December 22, 2023

December 22nd 2023The weekly new products podcast from Dental Products Report is back. With a quick look at all of the newest dental product launches, Product Bites makes sure you don't miss the next innovation for your practice. This week's Product Bites podcast features updated software from Medit. [2 Minutes]