Group Practices of All Sizes Need Infection Control Protocols

The end goal for both the single site and multi-site practice is the same—safety for patients and dental team members, alike. But how they get there can be very different.

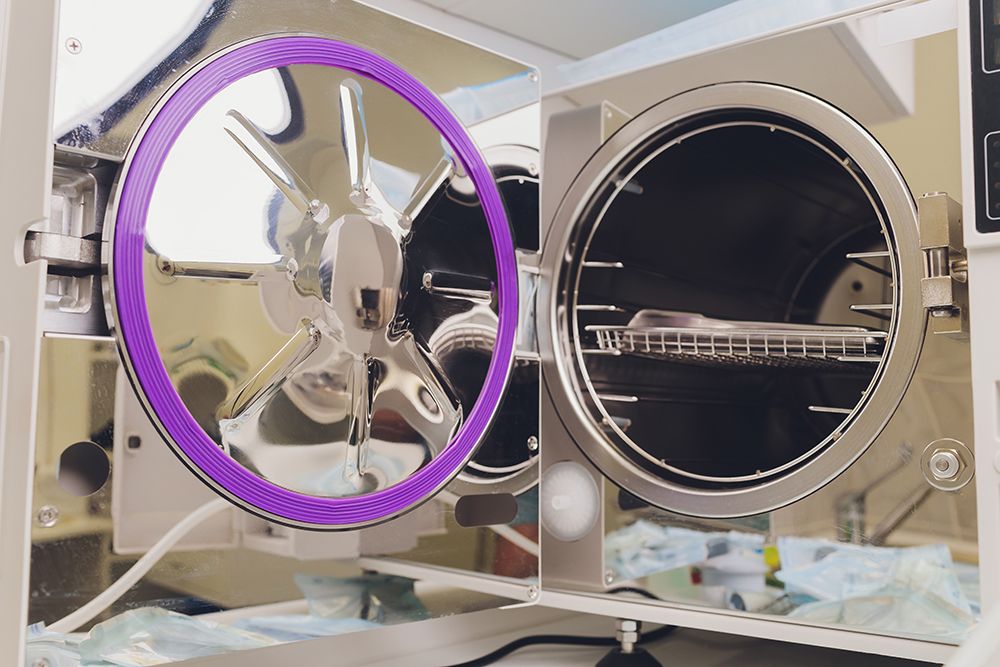

Евгений Вершинин /STOCK.ADOBE.COM

Not surprisingly, there are a lot of moving parts in a large machine. What may seem simply implemented in a smaller organization—like a single dental practice—might be more complex in a bigger group practice. The same is true when infection control practices are managed in both organizational sizes. While the result should be the same—safety and compliance—how practices with different organizational structures get to that goal can vary.

Definitions

It all starts with understanding what a Dental Service Organization (DSO)—or “Group practice”—means. There is no, one standard definition. A group practice could be as small as 2 locations, it could be as large as 1,000. Several locations may be governed—very strictly—by a single management authority, or they could just be a lone practice, taking advantage only of the group name and left to their own devices.

“The key issue here is scale,” Shannon Mills, DDS, observes. Dr Mills is a private healthcare consultant and Chair of the American Dental Association Standards Committee For Dental Products (SCDP) Subcommittee on Dental Infection Prevention and Control. “When you say the phrase ‘group practice’, there are so many different variations on that theme. They’re modeled very differently. Some of them provide a whole range of services for the practice, but they leave the practice management up to the practice, themselves. They may set some franchise rules where you must do this, or you must do that. This can be a good thing, as you have organizations that have very rigorous policies, standardizing infection prevention and control safety practices across the entire enterprise.”

Ultimately, what matters is how those infection control methods are put into practice.

“At the chairside, we have a set of guidelines,” Dr Mills says. “We have a set of principles. It’s imperative that each of these practices have an individual who has the training and the understanding of what they’re doing to manage for infection prevention and safety. Sometimes it’ll be more than 1 person. You have a safety person and an infection prevention person in some larger practices, but you must have someone who’s been properly trained with an understanding of the guidelines, understanding of the legal consequences and the licensure consequences of noncompliance.”

Uniformity

For DSOs and group practices—no matter how they are defined—what’s necessary is that safety practices are the same at each location.

“The biggest thing is consistency,” infection prevention speaker and consultant Karen Daw, “The OSHA Lady“ advises. “How do you maintain consistency in your safety protocols and policies across multiple sites? Especially as you’re growing, that can be a huge concern and a challenge. Ask, “How do I make sure that my expectations are being met at Site A the same as Site B?” And that’s where either working with a consultant—or at least having the proper checklists and templates—are going to be helpful, too. I also advise my multi-site locations to have a safety point person assigned to each location. They’re not going to do it all. You may have 1 person that’s in charge of overseeing safety for all the sites, and this person might make sure that they schedule the OSHA training for everyone. However, the point person is the eyes and ears of the individual location reporting upwards about safety concerns or suggestions.”

Consistency is necessary because, left to their own devices, it’s not guaranteed that each location is going to deliver the same results.

“Maybe the lead safety person will coordinate events around infection control and safety and bring in different speakers,” Daw says. “But at the individual sites, there’ll be somebody who’s overseeing the safety program, making sure they all are using the same OSHA manual. I’ve walked into some practices where they acquired 2 new locations, and I see that they’re all using different OSHA manuals and different safety systems. And I ask them, ‘How long ago did you acquire these 2 practices?’ And the response was, ‘Oh, it’s been over a year.’ That tells me they really haven’t done anything as far as reviewing their systems to ensure that they’re using the same manual, the same checklist, the same audit procedures, the same training so that everybody hears the same information and understands the expectations.”

Training

Training is a key part of infection prevention and compliance. That is, rules and regulations may or may not change, but team members can fall into bad habits or forget critical parts of the infection control process. Also, yearly training is an OSHA requirement. As such, having someone per OSHA who is knowledgeable in the subject matter perform the training is necessary. At the end of the day, that person will answer to OSHA about the training during an investigation. Why not have someone who focuses on just that?

“Corporate-owned practices might have a full-time person that oversees it, and then they appoint a point person at each location,” Daw says. “What I’m finding in what I call a ‘mid-tier’ or ‘expanding multi-site locations’, is that they don’t really have a full-time person or have a budget or a structure in place to have a full-time person oversee everything for them. So, having a safety committee would be helpful where you have these point people from each location all get together and discuss how they can streamline safety across all locations. What’s happening at Point A that’s not happening at Point B? What do we need to do to get everybody up to par?”

Sometimes practices rely on video or online trainings. And while those trainings are certainly quick and allow them to check off the box that training was accomplished, Daw observes that those trainings may not provide the same quality that an in-person trainer would.

“I see this many times, when they’re doing safety training, they watch a short video just to check off the box and they’re done,” she says. “And that opens them up to huge liability. Growing multi-site locations are still in a position to do team trainings. They might do it virtually, but everybody’s hearing the same information, and it’s a deeper dive on the safety and infection control topics that they need to be aware of. That’s another challenge that I think much larger organizations face. ‘How do we make sure that our continuing education is above and beyond?’

Not only, she says, does that live-person training provide more quality, but it also shows team members that their safety is important to practice leadership.

“When you look at the messaging that you give to your team, if you let them know, ‘Hey your safety matters so much to us that we’ve invested in top line systems and software, we bring in the expert speakers’,” Daw says. “‘We have full-day events where all we do is talk about compliance and safety and subjects that matter to you.’ I think that speaks volumes about what your organization values.”

While group practices may have someone whose whole job is to oversee training, Daw observes that there may be a little too much responsibility.

“A lot of the corporate practices that I’m aware of have a full-time person that’s overseeing the training,” Daw says. “I spoke with one who used to work at corporate-owned dental practices and left. Her biggest concern was that she was constantly under the pressure to feel like she knew everything. She had to do it all. She had to know it all. So, it wasn’t really a culture that encouraged her to seek outside help, to bring in an advisor, bring in a consultant.”

“I’m going to emphasize and reemphasize getting the right training,” Dr Mills adds. “Also, you’ve got to give that individual sufficient responsibility. Say, you’re the infection prevention and control person in this clinic, but we don’t give any authority and nobody in the clinic pays any attention to them. They just talk and everybody says, ‘I’m just going to do whatever I want, because the doc’s not going to make me.’ Then you’re going to have a failure somewhere along the line. There’ll be a breach, whether it’s a little one or a big one.

Recordkeeping

When one thinks of infection prevention, the things that come to mind are things like surface disinfection, instrument processing, and PPE, but one of the least sexy aspects is recordkeeping. For compliance sake, it’s necessary to keep track of several processes to prove that that work has been and continues to be performed correctly and consistently. The organizational structure of a DSO can make that process more involved, depending on its corporate requirements.

“If the central authority, the corporate headquarters, wants to take responsibility for auditing and evaluating the quality of infection prevention and safety in the practices, they can do that and they can ask them to provide information,” Dr Mills observes. “Send us documentation. Send us your spore testing results. Send us your water testing results, and we’ll keep that centrally. More likely what they’re going to do is what we did in the military—you’re going to do spot inspections. You’re going to audit them.

“For instance, you’ve got a headquarters in Kansas City, but you’ve got practices all over the country,” he elaborates. “You’re going to send either someone out to audit that practice—in Wyoming or South Dakota or wherever it is—or you’re going to ask them to submit documentation on a spot basis to show that they’re compliant.”

As the world moves to more digital recordkeeping, some places are still paper in nature. Group practices will likely require electronic records—as opposed to paper records—for the sake of consistency and efficiency.

“Single practices, I find, are kind of 50/50,” Daw says. “Some of them have electronic documentation, some of them like to use pen and paper, and that’s absolutely fine. If that system works for them, that’s great. It’s a little bit more difficult to have a paper system in multi-site practices. So, they tend to streamline it by going electronically. And that really does work well, because then if you have 1 person in charge of all the records and making sure all the record keeping is getting done, having a shared network folder that you can access across multiple sites is going to make that infection control coordinator’s job so much easier, from a record-keeping standpoint.”

The end goal for both the single site and multi-site practice is the same—safety for patients and team members, alike. But how they get there can be very different.

Product Bites – November 17, 2023

November 17th 2023The weekly new products podcast from Dental Products Report is back. With a quick look at all of the newest dental product launches, Product Bites makes sure you don't miss the next innovation for your practice. This week's Product Bites podcast features new launches from Intiveo, quip, Designs for Health, and Premier Dental.