DWS Systems unveils new lab and chairside digital dental solutions

The chairside and lab products are designed to quickly produce color-matched restorations.

Stereolithography leader DWS Systems announced today the formation of a dedicated dental business unit to transform digital dentistry by offering its latest solutions to this multi-billion dollar market. As part of this groundbreaking initiative, DWS plans to deliver both lab and chairside 3D printing solutions worldwide that can quickly create high-precision dental models, restorations and prosthetics with the push of a button. With DWS’s new products, dentists and lab technicians alike can reportedly create prosthetics matching the color of patients’ own teeth to give them a more natural look, a technological first in the industry.

The announcement was made in advance of the LMT Lab Day and Chicago Dental Society’s Midwinter Meeting, Feb. 22-24 in Chicago, where DWS plans to exhibit its complete range of dental products at each event.

“The formation of a dedicated dental unit leverages the most powerful portfolio of lab and clinic digital dental solutions on the market today. This positions DWS to better serve the American dental market, and offer its latest products to labs and clinics around the world," says DWS Founder and General Manager Maurizio Costabeber. "We believe that our decades of experience in digital dentistry, together with our advanced materials, push button user-experience, and precise, fast printing can successfully meet the demands of this multi-billion dollar market."

Trending article: 5 ways technology has changed the implant workflow

Autonomous lab and chairside solutions

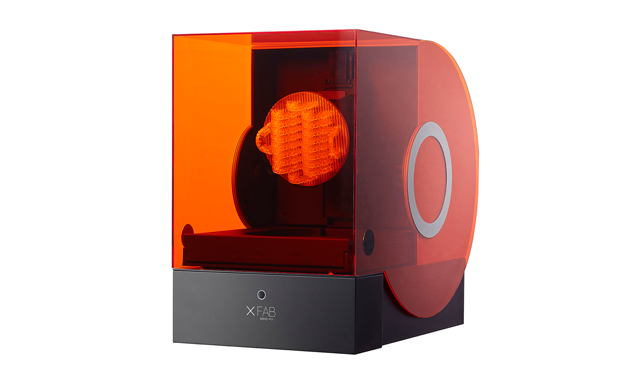

In Chicago, DWS will demonstrate two groundbreaking autonomous 3D printers: the LFAB, designed to produce dental models, surgical guides and prosthetics for dental labs, and the DFAB, which is tailored for the dentist’s office and can quickly deliver high-precision color-matched prosthetics. For use in its revolutionary FAB series printers, DWS also developed Temporis, a new class of biocompatible material for long-term use that meets European Union Class IIa invasive medical device requirements. As part of its North American expansion plans, the company also plans to seek required FDA clearances.

The FAB family of printers are said to be developed for dentists, prosthodontists and lab technicians with the purpose of increasing efficiency and reducing the number of procedures necessary to produce dental prostheses. It reportedly can produce up to five-element precision bridges, ensuring an accurate fitting and a correct occlusion in less than 20 minutes. Independent studies and tests on Temporis have reportedly shown mechanical strength values that are comparable to well-established traditional restorative resin materials.

Natural colored dental prosthetics

While patients want prosthetics that feel like real teeth, they also want them to look natural and match the color of their own teeth. Both the LFAB and DFAB 3D printers are designed to deliver customizable colored restorations using light curable composites. Additionally, the new DFAB is said to effectively replicate patient-specific color gradient using DWS’s revolutionary Photoshade technology to improve overall prosthetics’ appearance. For the first time, dentists can color match and 3D print a functional patient-specific restoration in their office during a single patient visit.

Check out DPR's coverage of the 2018 Chicago Midwinter meeting here

Fast, easy, precise

In Chicago, DWS also plans to unveil the XCELL 6000PD, reportedly the first-ever fully automated dental 3D printer that delivers a full range of dental treatments with the click of a button. The high-speed 3D printer is said to increase operational efficiency with its unique cartridge system that makes it easy for dental technicians to change printing materials. The all-in-one automation completely reportedly eliminates the post-processing labor associated with washing and curing. The XCELL 6000PD can effectively address a broad range of dental applications, including dental models, temporary prosthetics, castable copings and aligner manufacturing. It can also be used for surgical guides, partial frameworks, implant models for analogs and restorations, such as crowns and bridges.

The company invites interested customers, strategic partners and qualified resellers to visit DWS at LMT Lab Day in booth #B52 and Chicago Dental Society’s Midwinter Meeting in booth number #4434 from Feb. 22-24 in Chicago to experience its entire portfolio in action.