Quiz - Do You Know These 5 Surprising Facts About 3D Printing?

When 3D printing entered the retail market, some futurists predicted that it would be the beginning of the third industrial revolution. Economists and industry thought leaders predicted a boom in several areas that would be impacted by 3D printing the most: apparel, automotive, construction, medical, and even space and firearms.

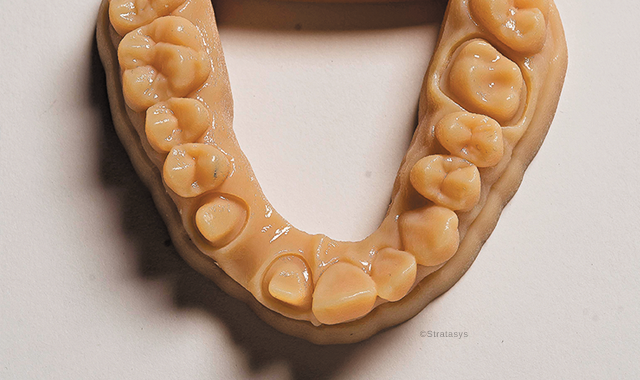

It would take a few more years before we realized exactly how 3D printing would work with oral scanning and CAD/CAM to create immediate in-office models for a variety of dental applications.

Take this quiz to find out how much you know about the creation and rise of 3D printing, and how it’s predicted to impact the dental industry in the next decade.

To first question

See correct answer and explanation

Invented in 1981, 3D printing wasn’t available for industry use until 2012. Additive manufacturing (or AM, an umbrella term for the many techniques used for 3D printing) was first invented in 1981 at the Nagoya Municipal Industrial Research Institute, where Hideo Kodama developed a use for stereolithography to generate 3D objects. It wasn’t until 1984 that Chuck Hull developed a system that was capable of printing a 3D part. Finally, in 1988, Scott Crump invented fused deposition modeling (FDM), the technology that drives most of today’s professional and consumer 3D printers. In October 2012, 3D printing systems were available on the industrial marketplace at a high cost. (Source)

To next question

See correct answer and explanation

Using a simple combination of candle wax and polyurethane, Crump used a hot glue gun to make a 3D model of a toy frog for his young daughter, layer by layer. It was through this that he thought of the idea to automate the process and invented the fused deposition process. Years later, in 1991, he would go on to start his own printing company with his wife, Lisa. Stratasys has been a leader in 3D printing ever since. (Source)

To next question

See correct answer and explanation

Because the dental industry requires such a large number high performance and high value parts, 3D printing is predicted to change the production game completely in the next few years. Worth $780 million in 2015, SmarTech Markets Publishing predicts the 3D printing market in dentistry alone will be worth $2 billion in 2016 and $3.1 billion by 2020. (Source)

To next question

See correct answer and explanation

While desktop 3D printing came on the market in the early 2010s, most printers were not industry-specific. In 2013, Stratasys changed that: the Objet30 OrthoDesk 3D Printer was introduced in March of that year.

While subtractive manufacturing had been around for decades through CEREC, additive manufacturing made chairside dentistry even more advanced and intricate. With oral scanning, CAD/CAM design, and 3D printing, the dental industry was able to further invest in 3D printing on a smaller level, allowing dentists and orthodontists to bring the lab into their clinics while utilizing a wider range of materials and improving details on 3D printed objects. (Source)

To next question

See correct answer and explanation

The Federal Drug Administration approved a 3D printable denture material base last year, and more end-use materials are in various stages of the approval process. Dr. Jason Lee, the creator of the new technology approved last year, said: “The material is a light-cured resin indicated for fabrication and repair of full and partial removable dentures and baseplates, which will eventually replace traditional heat-cured and auto-polymerizing conventional denture making methods.” (Source)