Closer Look: The Benefits of Printing at the Practice

How adding a Formlabs 3D printer is helping one dental practice increase treatment efficiency while reducing costs.

Whether it concerns adding a cone beam 3D-imaging system or an intraoral scanner, Benn Lieberman, DMD, says staying up-to-date on the latest clinical technology is always a priority for his practice in Mount Kisco, New York.

Dr Lieberman and his 2 partners run South Bedford Oral and Maxillofacial Surgery (SBOMS), a busy practice focused on placing dental implants as well as orthognathic and reconstructive surgeries. The practice has had its eye on adding a 3D printer for some time, but it was a recent remodel that led to the investment.

“We completed our renovation about 6 months ago and we now have a dedicated spot for our 3D printing. We’ve been very excited about that addition to our practice,” Dr Lieberman says.

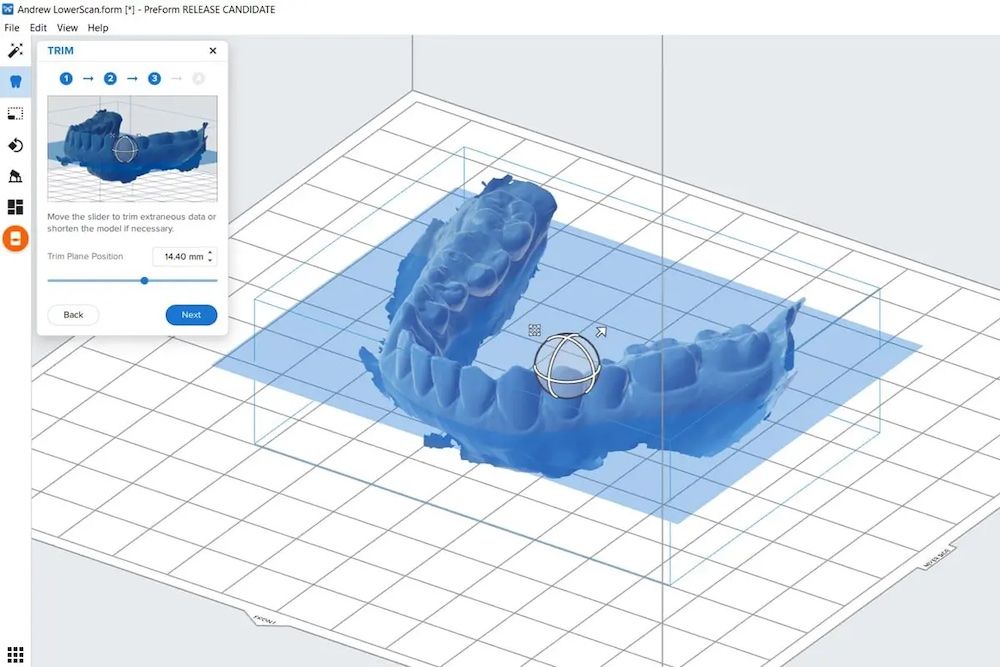

Scan to Model is a new tool for Formlabs’ PreForm software designed to convert intraoral scans into 3D printable models quickly via a simple workflow. Clinicians can create models for diagnostics, thermoformed orthodontic appliances, and fit checks from digital impressions uploaded to PreForm’s Scan to Model tool, and printed with a Formlabs 3D printer. The new tool is said to reduce turnaround time and simplify model 3D printing.

The practice selected the Form 3B printer from Formlabs, which has a compact footprint. Additionally, it delivers the speed and quality the practice was looking for in the production of implant surgical guides, as well as the models Dr Lieberman likes to use to evaluate occlusion and other orthognathic treatment outcomes.

The practice is still refining workflows to include digital impressions of every surgical patient, but the 3D printer has been a great fit overall. Dr Lieberman says the practice works with an IT provider for their technical setup needs, which has made integrating the printer simple. Although Dr Lieberman has had some prior 3D printing experience, at Jacobi Medical Center in the Bronx, where he serves as director of oral and maxillofacial surgery, he has been thrilled with how quickly and easily his team at SBOMS has taken to the technology.

“Even more important than my comfort with it is that the staff has to be comfortable with it,” he says. “It’s been great. We’ve printed out a bunch of guides, and they fit well. Once we’ve learned our systems and our processes, my staff is really good with technology.”

One of the printer features Dr Lieberman has been able to try out is the recently launched Scan to Model capability, designed to make model production more efficient. He says the system is fairly easy to use and that he and his team are becoming more proficient at setting up models or guides for the printer.

“So far, it’s just a few clicks and we’re good to go,” he says.

The models work great for Dr Lieberman’s occlusal analysis. Additionally, he appreciates being able to store a digital instead of a physical model because it cuts down on the space required for storage and makes it easier to find if it is needed in the future. However, the surgical guides are what the practice is using most often right now.

Prior to adding the Formlabs printer, the practice sent cases out for surgical guide design and production. The quality of the guides was great, but with the labs being produced on the west coast, timing was always a challenge.

With the printing taking place in-house, the practice can schedule and complete cases in a shorter time span. These appointments are also more predictable now because the surgical guides are no longer delayed in shipping.

“It’s not that it’s a significant time savings in terms of staff time, but it’s definitely overall money saving because the guides are significantly less expensive. So we don’t have to pass [extra] cost through to our patients, which they like.”

At SBOMS 2 treatment coordinators are in charge of making sure the guides are ready for every guided surgical appointment. According to Dr Lieberman, they are the real experts with the system and have made it possible for the busy practice to add 3D printing technology without slowing patient care.

“I don’t know that I could do this without them because of the volume we’re doing,” he adds.

The printer is a perfect fit for the dentistry and oral surgery performed at SBOMS. Dr Lieberman believes that 3D printing has a big part to play, not only in the dentistry of the future, but also in the treatments that practices are performing right now.

“This is not something that’s the future. This is something we should be doing today,” he says.

ACTIVA BioACTIVE Bulk Flow Marks Pulpdent’s First Major Product Release in 4 Years

December 12th 2024Next-generation bulk-fill dental restorative raises the standard of care for bulk-fill procedures by providing natural remineralization support, while also overcoming current bulk-fill limitations.