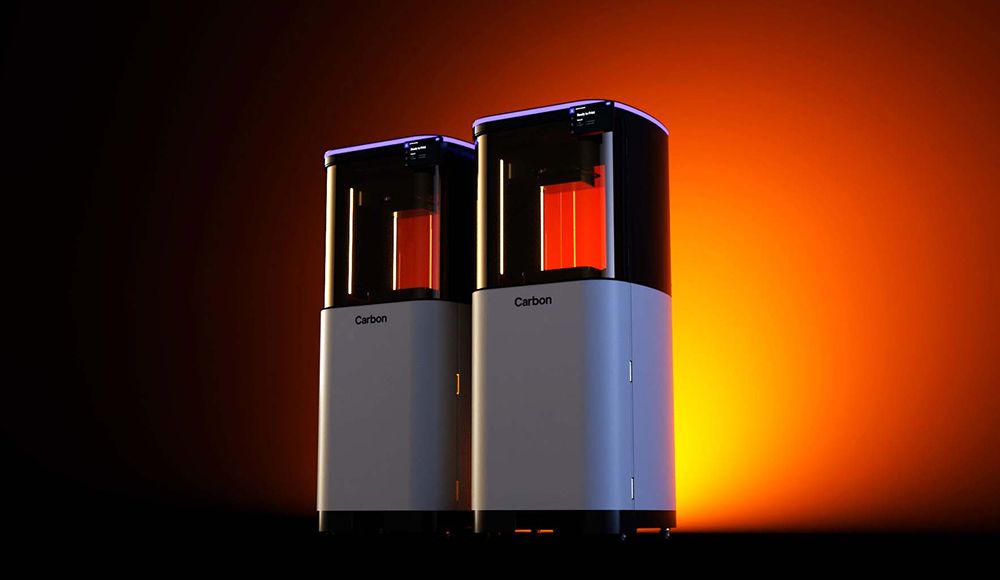

Carbon Launches M3 and M3 Max 3D Printers Designed for Increased Speed, Reliability and Accuracy

The company’s new 3D printers provide up to 2.5X throughput improvements for dental models compared to previous generations and are designed to save dental labs both time and money.

Carbon announced today that it is further evolving its idea-to-production platform with the all-new M-Series 3D printers. The M3 and M3 Max are designed to leverage the next generation of DLS printing technology and provide up to 2.5X throughput improvements for dental models compared to previous generations, driving further value for dental labs.

The next generation of Carbon printers—the M3 and the M3 Max—provide an advanced end-to-end idea-to-production platform when combined with the Carbon Design Engine™ and Carbon DLS materials. The M3 is designed for faster printing, a simpler print experience, and improved cross-build consistency. The M3 Max offers these same benefits as well as a true 4K light engine, enabling double the build area with the same pixel size and density. Both printers offer the same wide range of high-performance materials tailored for applications across dental and lab needs.

“Carbon printers have been a workhorse in our manufacturing center and create high-quality dental models print after print,” says Jeff Lowthorp, Argen vice president, business development. “Having experienced first-hand what previous generations of printers are capable of, we look forward to this step in technology that will save us time and money as we continue to produce high quality products in a shorter period of time.”

Carbon's M3 printer is designed for faster printing, a simpler print experience, and improved cross-build consistency.

“Dental labs ranked Carbon’s printers as the most preferred and most reliable 3D printers used in dental labs today according to a 2021 NADL survey, and this next generation of printers—combined with a wide range of fully validated materials—allows labs to create high quality dental products quicker and more efficiently than ever before,” Carbon’s Chief Product and Business Development Officer Phil DeSimone says. “This will provide further time and money savings for our customers as they provide the consistently high quality products that Carbon has become known for. This will further separate the forward-thinking labs using additive manufacturing on a daily basis.”

According to the company, a recent survey of US dental labs showed that Carbon 3D printers once again outperformed the competition in the areas that matter most, including being the most preferred printer, most reliable, the brand with the highest average daily print hours, and the highest Net Promoter Score (NPS) for large labs. Additionally, the survey found that 3 out of 5 dental labs now use 3D printers, with an additional 35 percent planning to offer 3D printed parts in the future. With the top reasons for wanting to offer 3D printed parts being higher production capacity, faster production times and more consistency, the M3 printers are purpose-built and designed to include the key features important to dental labs, including:

- Faster printing: Thanks to better heat management, the next generation of DLS printers delivers more throughput per square foot in thermally limited scenarios, like dental models, with throughput improvements for models up to 2.5x what previous generations were capable of.

- Simplified printer experiences: The next generation of DLS printing creates substantially lower forces on the part and introduces closed-loop control of force and temperature, reducing failure modes and simplifying the print experience.

- More consistent parts: The next-gen of DLS printing reduces the variation in parts across a single-build by up to 50%—translating to less variation in general accuracy and more production repeatability in engineering resins.

- Fast and easy installation: The M3 is designed to be installed in hours, with the ability to relocate the printer within customer facilities as they see fit.

- Larger Build Area: The M3 Max printer offers double the build area with the same pixel size and density as the M3 printer, making it ideal for dental labs producing many smaller parts with similar quality.

The M3 printer is now available for order and shipping and the M3 Max printer is available for order and is expected to ship in the second half of 2022.

ACTIVA BioACTIVE Bulk Flow Marks Pulpdent’s First Major Product Release in 4 Years

December 12th 2024Next-generation bulk-fill dental restorative raises the standard of care for bulk-fill procedures by providing natural remineralization support, while also overcoming current bulk-fill limitations.