Technique: How going digital can revolutionize esthetics

Steve Daggett, CDT, shows how using a digital workflow, including an intraoral scanner, CAD software and a dental mill, can result in tremendous collaborative and esthetic possibilities.

We rely on digital advancements and technology as an integral part of our own day-to-day lives, and the rapid advancement of digital technology for the dental industry means that we can’t ignore it in our professional lives either.

Since our lab began accepting digital scan files more than six years ago, we have seen firsthand how digital scan files can improve dentist/lab communication, contribute to overall increases in efficiency, and enable better accuracy. More and more dentists are beginning to adopt digital scanning technology, and the results we’ve seen in our lab make it clear that this is a technology that has numerous benefits to dentists, labs and patients. At D&S Dental Laboratory, the integration of digital technology is key to our success. It enables easier client communication, more efficient workflows and better overall results.

With traditional impressions, there is more time and energy involved in the process before we may detect an issue. When our lab encounters an issue with a digital scan, we can quickly call the dentist and email them the scan file. Then, we simply point out in real time where any details are missing from a scan, and we can get the final product to our customers quicker. When we communicate with our dentists about the benefits of digital scanning, time-savings is certainly a popular topic.

To that end, we make it a top priority to utilize a digital workflow for as many steps as possible. Our lab can receive digital scan files from customers in minutes, allowing us to avoid spending time pouring up a mold and scanning it into the system, as we must do with traditional impressions. Increased efficiencies in workflows and less chance of error benefit both the lab and the dentist.

With digital scanning, our remake percentage is less than 0.5 percent, which is a huge advantage. We have extreme confidence in scan files, enough so that we often are able to utilize model-less workflows. Currently, our lab is around 98 percent digital, and it’s extremely efficient for us. We can use state-of-the-art technology for our clients, and we can offer the best possible product at the best possible price. With digital comes consistency and confidence, and it’s something that allows our lab to perform at the highest level possible.

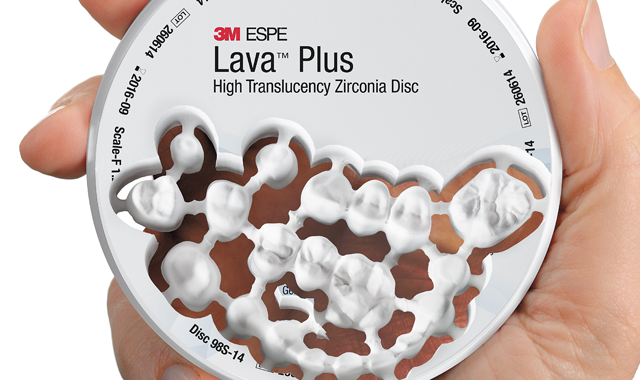

Fig. 08 The Lava Plus zirconia disc available from 3M provides another option for labs.

Fig. 01 The Lava Plus zirconia disc available from 3M provides another option for labs.

High performance zirconia

Beyond the advancements in digital scanning that improve lab efficiency, patient communication and results, new materials in the industry are providing stronger, more flexible and esthetic restoration solutions. Our lab has transitioned from classic 3M Lava™ Zirconia to 3M Lava™ Plus High Translucency Zirconia-utilizing a new generation of zirconia that maintains strength, while providing improved esthetics.

The unique zirconia powder and shading liquids offer the ability to create highly customized restorations, and the material was recently made available in a disc format for open-source milling (Fig. 1). Now, the Lava Plus High Translucency Zirconia Disc is indicated for full-arch restorations, providing the flexibility that many labs seek.

The improved esthetics of this material enable labs to choose what works best-either monolithic restorations, or to stack or press porcelain for a traditional layered restoration. The greater level of translucency is made possible by high quality processing of the zirconia to minimize impurities and structural defects. Our lab has found that this high quality processing contributes to fewer problems with fracturing during the milling process.

Esthetically speaking, a primary standout aspect of this material is the fact that it matches the VITA® Classical A1-D4 shades, plus two bleached shades. Many materials on the market are becoming more esthetic and offering flexibility-and this combination of coloration possibilities and high material translucency means that labs can achieve outstanding esthetics regardless of whether they are creating veneered or monolithic restorations.

The below monolithic crown case was completed by our lab using an all-digital workflow. We utilized scan images from the 3M True Definition Scanner and 3M Lava Plus High Translucency Zirconia for the restorative material.

Fig. 01 The initial crown prep.

Fig. 02 The initial crown prep.

At the dental office

01 | The patient had a large MOD amalgam restoration with recurrent caries. Due to the size of the restoration, its location in the mouth, and the patient’s bruxism, it was determined that treatment with a monolithic Lava Plus zirconia crown would be most appropriate. The amalgam and caries were removed and the tooth was prepared for the crown (Fig. 2).

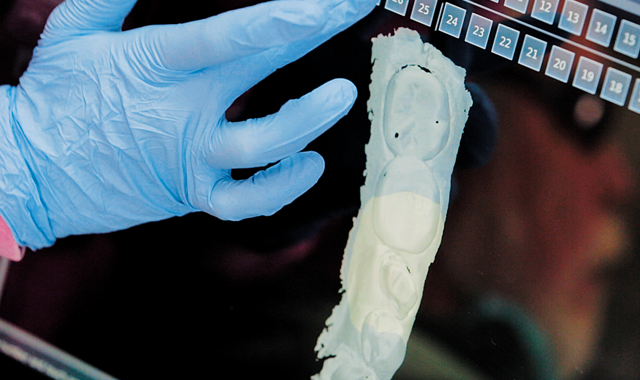

Fig. 02 A digital scan was captured with the 3M True Definition Scanner.

Fig. 03 A digital scan was captured with the 3M True Definition Scanner.

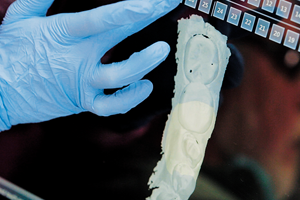

01 cont'd | The 3M True Definition Scanner was then used to capture a digital scan of the mouth (Fig. 3).

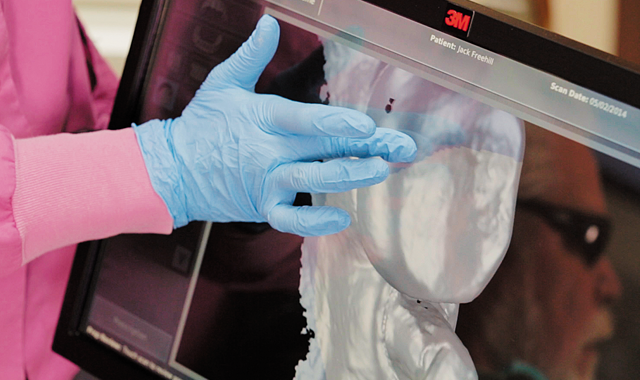

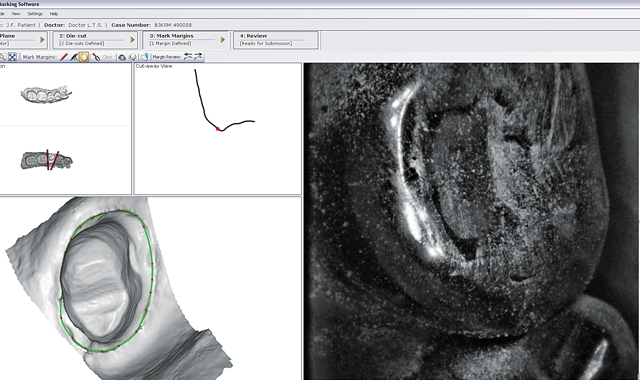

Fig. 03 The scan and margins were reviewed and approved on the monitor.

Fig. 04 The scan and margins were reviewed and approved on the monitor.

01 cont'd | After reviewing the scan for completion, the prescription was submitted to the laboratory via the 3M Connection Center (Figs. 4-5).

Fig. 04 The prescription was submitted to the laboratory through the 3M Connection Center.

Fig. 05 The prescription was submitted to the laboratory through the 3M Connection Center.

Fig. 05 Software was used to mark the margins of the crown.

Fig. 06 Software was used to mark the margins of the crown.

At the lab

02 | Once the lab received the scan, software was used to mark the margins (Fig. 6). The scan was then imported into CAD software and the full contour design was created (Fig. 7; below).

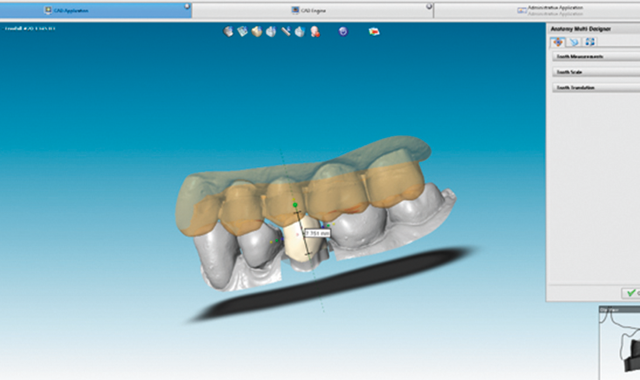

Fig. 06 Full contour design is created.

Fig. 07 Full contour design is created.

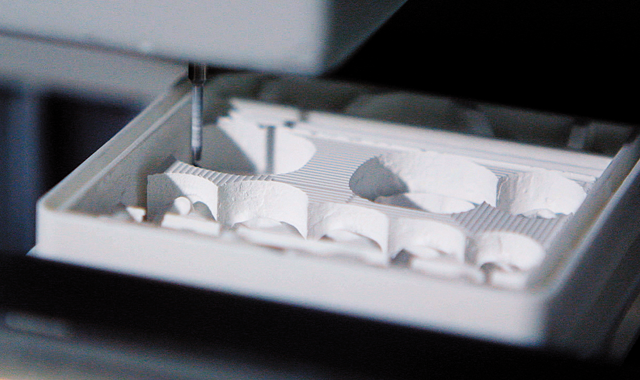

Fig. 07 Crown is milled from a Lava Plus zirconia block.

Fig. 08 Crown is milled from a Lava Plus zirconia block.

03 | The CAM file was calculated by the software and the crown was then milled (Fig. 8). Going forward, new zirconia discs offer another solution for labs.

Fig. 09 The milled Lava Plus crown in its green state.

Fig. 09 The milled Lava Plus crown in its green state.

04 | Once milling was complete, the block/restoration was removed from the mill and a high-speed fine diamond bur was used to cut the crown from the block. The sprues were smoothed and the green state Lava Plus crown was cleaned to remove any excess dust (Fig. 9).

Fig. 10 The crown was immersed in dying liquid.

Fig. 10 The crown was immersed in dying liquid.

05 | To stain the crown, a mixture of W3 and A1 Lava Plus shading liquids were applied with a brush to the incisal half of the crown. Color markers were used to track where the incisal shade was placed. The entire crown was then immersed for two minutes in the body shade of Lava Plus shading liquid (Fig. 10). The crown was then carefully removed and excess liquid was blotted from the surface.

Fig. 11 The crown is placed in a sintering tray and fired.

Fig. 11 The crown is placed in a sintering tray and fired.

06 | The crown was placed on a sintering tray and fired (Fig. 11). Our laboratory has found that Lava Plus zirconia is able to produce consistent results with a fast firing cycle of just four hours, which includes drying and cooling time.

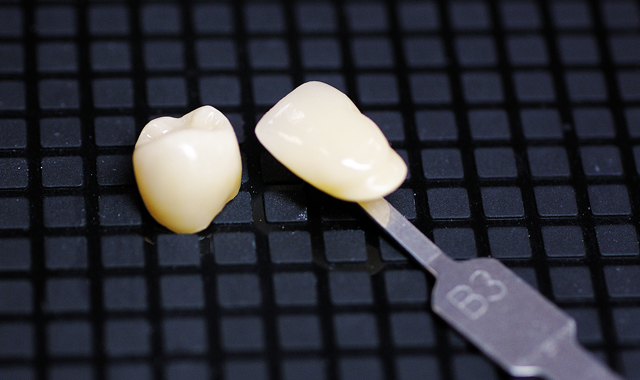

Fig. 12 A final shade comparison was done after staining and firing.

Fig. 12 A final shade comparison was done after staining and firing.

07 | After firing was complete, final contouring and characterization were performed, including final finishing of the margins and minor adjustments to interproximal and occlusal contacts. The final shade is confirmed (Fig. 12) and the crown is prepared to be returned to the dentist for final seating (Fig. 13; below).

Conclusion

The efficient workflow described here is very typical for a case utilizing the 3M True Definition Scanner and Lava Plus zirconia. With a highly accurate digital impression and an esthetic and strong monolithic crown, workflows are simplified for both the dentist and the laboratory. In the end, the patient benefits from a natural-looking restoration that will stand up to wear in the mouth and continue looking great for the long term.

Fig. 13 The final crown on the model.

Fig. 13 The final crown on the model.