New options in implantology

Jason Atwood of Core3dcentres explains how dental labs of all sizes can get into implants, and how Core3dcentres can help with that workflow.

Implantology is increasingly a huge growth area within dentistry. As labs become more involved in the implant workflow, it’s increasingly important for technicians to keep up-to-date with the latest in implant trends, from abutments to restorative solutions.

Jason Atwood

One avenue that some labs take is to work with an outsourcing partner for some or all of the implant workflow. Core3dcentres is one such partner, offering a variety of validated implant workflow options with a number of implant manufacturers. We recently spoke with Jason Atwood, Senior Digital Solutions Advisor at Core3dcentres, about what labs need to know about implants, how Core3dcentres can help and how labs can balance in-house design with outsourcing needs.

How has the world of abutments (and more broadly, implantology) changed over the last 12 months?

Certainly, implantology is becoming more and more user-friendly at all levels and the range of available options to resolve cosmetic and functional issues continues to grow exponentially, as has the number of practitioners entering the field. This has also lead to increased challenges for the dental technician-requests for faster turnaround; incorrect angulation; implants placed too deep sub-gingivally; obsolete systems; and more.

If a lab is concerned about making sure the abutments it is working with will work with the implant system, how can Core3dcentres make sure this happens?

Core3dcentres has always invested heavily in strategic partnerships to ensure clear and concise verified workflows. Validated by leading CAD software providers such as 3Shape™, Dental Wings™ and exocad™, Core3dcentres® digital implant library contains the majority of the branded implant connection platforms (19 brands and 105 different connections-with more in development), fully supported by a validated work-flows. This gives Core3dcentres and its laboratory partners a unique ability to have one system utilized by both the intraoral and laboratory scanner, making this a cost-effective solution for both the clinician and the laboratory.

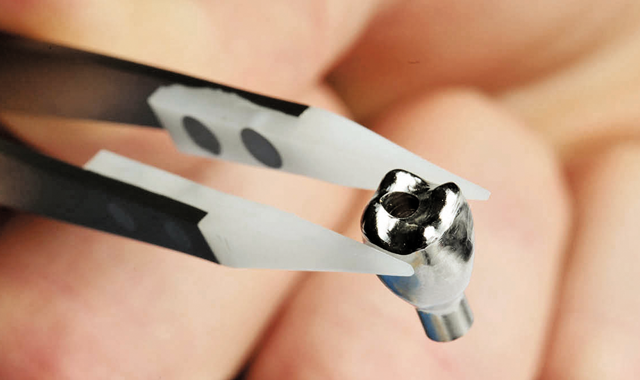

We match this with our range of Core™ screw or cement-retained custom implant abutment options (Custom Titanium, Zirconia or Hybrid) and precision-made implant componentry including dual-use lab/intraoral scan bodies (radiopaque and autoclavable); lab analogs; digital model analogs; screws; titanium bases; hybrid abutments; titanium abutments and bars; and milled frameworks in PMMA, Zirconia, Titanium and CoCr for screw-retained bridges.

How Core3dcentres are equipping labs for the future

Most important, Core3dcentres offers a comprehensive Root-to-Tooth Implant-Abutment-Crown Warranty. Core3dcentres fully warranties our abutments and will replace the implant, abutment and crown at no charge (certain conditions apply).

What’s the advantage of outsourcing custom abutment work over doing the work in-house?

There are often many variables involved in the design and manufacturing of custom abutments. The time alone spent designing can affect the output of a laboratory at any time, let alone the upfront cost of the machines and equipment needed to provide the kind of consistent quality and outcome most labs desire. This can be a major drain on any laboratory. As a result, many labs are opting out of the investment and partnering with companies that can provide the necessary services.

Through our partnerships, our extensive R&D activities and the broad range of clinical situations we see on a day-to-day basis, our support, design and production teams are well-versed in all implant systems and are able to guide our customers to the best options.

Next page: Unpacking the process of working on an implant case with Core3dcentres ...

What does the process look like for a lab who wants to work with Core3dcentres? Take us through that.

There are two approaches for our partners. Some labs have begun to integrate digital technology into their workflow. They have scanners, the ability to design their own restorations and even some milling capability. Under this scenario, the lab will electronically send their completed designs to Core3dcenters for quality fabrication. Once milled, we ship the product to the laboratory unfinished-this is important to note, we always keep the laboratory in the loop. The laboratory is then able to finish the product with its own personal touches.

Must read: How to understand and handle today's digital workflow

Under the second option; if a laboratory has made the decision to avoid the digital arena, but would still like to provide their doctors with all the latest options, Core3dcentres can receive the models, scan, design and manufacture on their behalf. We use the “top down approach,” which means we design the full contour first, then we design our abutments within the space created. Then we take esthetics into account. Next, we take esthetics into account, with a full palette of shades available for a seamless transition between zirconia abutment and crowns. Customized height, width, margin and angulation can all be specified. Even large full arch or full mouth reconstruction cases can be fabricated. We also offer a Titanium Base for individual milled hybrid Zirconia/Titanium abutments (this includes a screw) which allows metal-to-metal connection between screw and abutment to help prevent fracturing.

What advantages does Core3dcentres offer?

With our extensive range of options, and inclusive pricing, we believe Core3dcentres offers the best value in the market today. However, we also believe our value goes beyond those two aspects.

Trending: 10 implant trends you NEED to know

At Core3dcentres, we understand that getting into the digital arena of the implant-based laboratory field can be a daunting task. As we’ve discussed in the past, we consider our customers our partners. We are here to educate and assist in building an understanding of the full digital workflow. Our goal is to allow our partners to dramatically expand their range of implant-based capabilities-without the investment! We are structured to allow our partners to add as much, or as little, of our experience, reliability and an in-depth knowledge of the digital world to their team as they wish.

Do you work with implant companies to make sure all components are safe and reliable? How so?

Absolutely. As mentioned earlier, we are a Certified BioHorizons® Milling Center and an Authorized Milling Partner for Thommen, as specific examples. Beyond that we work, grow and communicate with major implant companies around the world on a regular basis.

What kind of abutment options does Core3dcentres offer? How do you help labs make the right choice?

We support 19 different implant manufacturers offering full titanium, cobalt chrome and zirconia/titanium hybrid options; in simple abutments or complex full contour screw-retained crowns (even in titanium). Beyond that, our ability to bundle abutment and crown options (in a wide variety of materials) results in a complete one-stop implant-crown solution; for real savings in overall restoration cost and turnaround time. By offering such a wide range of products on so many different platforms, we can provide customers the array of restorative options they need to meet the demands of a complex implant-based world. Our team is always available to discuss/plan these options by phone or online.

The List: Top 5 CAD/CAM terms you need to know

How do you help labs ensure the restorations they build on top of the abutment will be successful?

Our team has many years of experience in “what will work” and watch for cases we think may result in difficulties at the final restoration stage. We pride ourselves as the best in customer service. We offer tools such as Brightsquid, which also has a 3D viewer to allow outside labs to review designs before fabrication. Additionally, we offer training through Core3daCADemy courses and webinars. All of this support is what makes the real difference in selecting an abutment partner.

Oral Health Pavilion at HLTH 2024 Highlighted Links Between Dental and General Health

November 4th 2024At HLTH 2024, CareQuest, Colgate-Palmolive, Henry Schein, and PDS Health launched an Oral Health Pavilion to showcase how integrating oral and general health can improve patient outcomes and reduce costs.

Episode 31: Dentsply Sirona Implant Announcements

September 30th 2021DPR’s Editorial Director Noah Levine sat down with Gene Dorff, Dentsply Sirona’s group vice president of implants and Dr. Dan Butterman to review several big announcements the company made in the arena of implants during Dentsply Sirona World 2021 in Las Vegas.