5 things you need to know about 3D printing

3D printing isn't done revolutionizing the dental industry. Here's what you need to know to stay ahead.

You’ve been hearing it for years this point: “3D printing will revolutionize the industry,” “This technology is going to make this other product obsolete,” “Invest in 3D printing before it’s too late!”

3D printers aren't new, but they are continually being made cheaper, better and more accessible than ever. This means that not only do you have to track the 3D printing revolution as it relates dental industry - you also have to track the revolution being brought to 3D printers themselves. It’s a lot to take in, but we’re here to help.

Here are 5 things you need to know about where 3D printing is now - what it’s being used for, how to best utilize it - and where 3D printing will be in the future. 3D printing shouldn’t be intimidating, so here’s how you can stay on top of the 3D printing revolution.

Click through to see the 5 trends in 3D printing

Why the future looks bright for 3D printing

The mass emerges slowly and steadily, still wet from the primordial ooze from which it originated. As it rises, its features are gradually revealed. With every passing moment, it becomes more definite, more apparent that something it is metamorphosing from, seemingly, nothing.

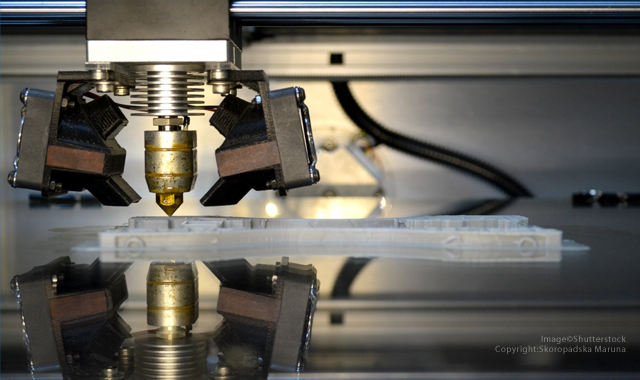

No, this isn't a scene from the 1991 movie “Terminator 2” – it is the model of a lower arch being 3D printed on an M2 3D printer, made by manufacturer Carbon.

While this technology is different from conventional 3D printing technologies, there are more improvements ahead. Currently, 3D printing at dental labs is only used for models and surgical guides for implant placements, but expect important changes in the next year or so - and expect even more Earth-shattering advancements in the years to come.

Click here to read more about the future of 3D printing

7 ways 3D printing is changing everything

CAD/CAM changed the face of dental laboratory work about 15 years ago, and you’d be hard-pressed to find a lab that hasn’t heard about CAD/CAM, isn’t considering CAD/CAM or doesn’t already own a CAD/CAM system. And while the basic system is revolutionary, it has continued to grow and evolve.

One such advancement comes in the form of 3D printing. Labs can derive a lot of use from 3D printers and their prices are coming down, so now might be a good time to consider adding the technology to one’s CAD/CAM solution.

The state of 3D printing

Digital technology is creating workflows never seen before in the dental industry. The pathways of sharing information and collaborating on cases are becoming more abundant and easier to use. As members of the restorative team strive for more accuracy in all aspects of the process, from implant placement, impression taking and prosthesis creation, one tool that is sure to get used more often is 3D printing. There are very few things that have advanced as quickly as 3D printing over the past few years. This advancement has come from the convergence of hardware and material development happening simultaneously. Along with this external development, the people using the 3D printers have also learned to optimize both the files they are printing and the machines they are using.

The amazing thing is that this could just be the tip of the iceberg as it relates to 3D printing. As material manufacturers continue to strive for government approval for intraoral use, the printer and software companies, and the forward-thinking people operating the machines, continue to gain knowledge of the possibilities offered by additive manufacturing. This technology will grow exponentially.

Click here to see how 3D printing will grow.

How is dental technology REALLY being used?

CAD/CAM and digital dentistry are major forces driving the industry, but to what extent? To find out, Digital Esthetics conducted a survey to determine how technology is driving dentistry. The survey asked respondents about how they utilize technology, what kinds of equipment they use and how they interact with their lab or doctor.

Click here to find out how 3D printing is really being used in the real world.

5 workflows changed by 3D printing

3D printing is changing-and disrupting-all kinds of dental workflows. Here are five dental processes that have been revolutionized by 3D printing possibilities:

01 | Model making.

This is the most common use (so far) for 3D printing. Whereas models used to require time to mix stone and then careful set up, models can now be printed using the same CAD file used to create the restoration. It’s an easy way to naturally fit 3D printing into a digital workflow. Plus, it provides a great visual aid for dentists-and a bonus technological marvel for patients to take home!

Click here to see all five workflows.

Product Bites – January 19, 2024

January 19th 2024Product Bites makes sure you don't miss the next innovation for your practice. This week's Product Bites podcast features new launches from Adravision, Formlabs, Owandy Radiology, Henry Schein Orthodontics, Dental Creations, and Dental Blue Box. [5 Minutes]

3D Systems Garners FDA Clearance for Multi-material, Monolithic Jetted Denture Solution

September 17th 2024The company’s unique multi-material, single-piece dentures are designed to offer a combination of distinctive break resistance and outstanding esthetics for enhanced patient experience, and Glidewell labs are currently implementing the solution.